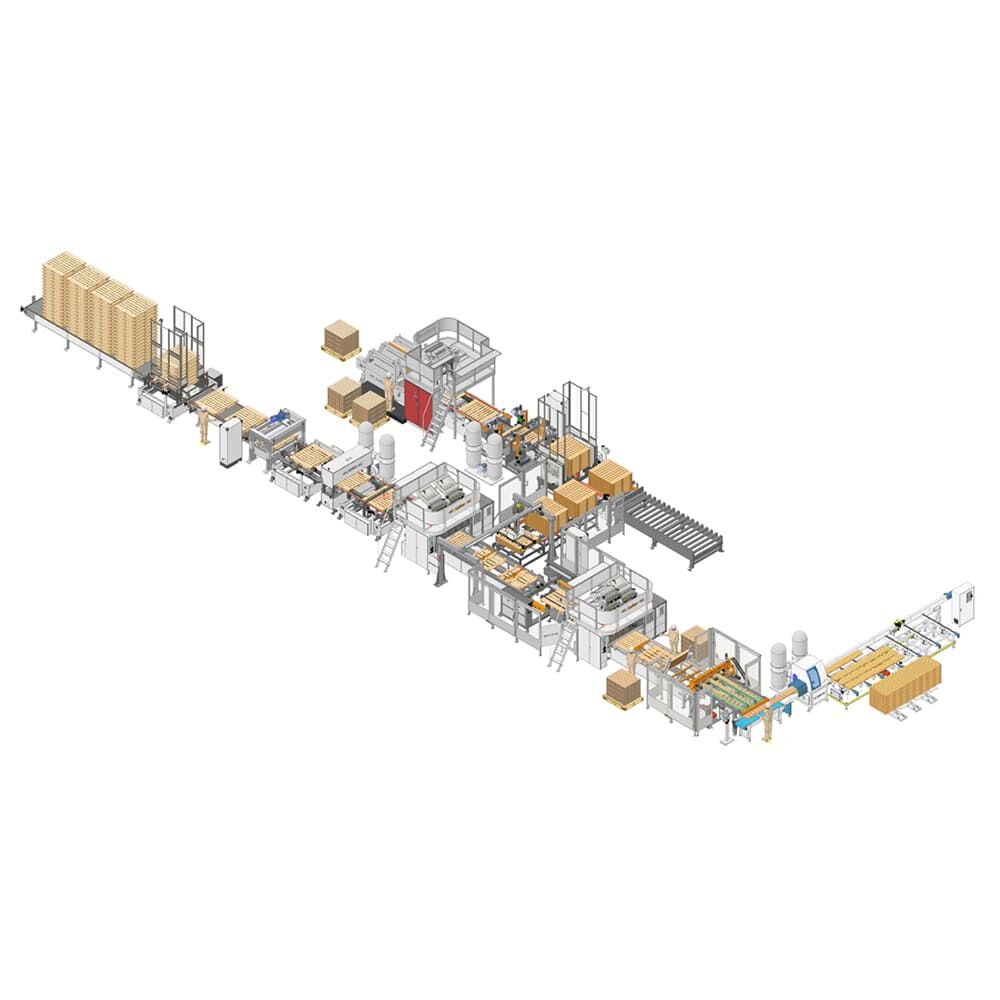

HICAS bietet hochwertige, maßgeschneiderte Holzpalettenmaschinen mit 25 Jahren weltweiter Erfahrung. Durch ISO9001-, UL- und CE-Zertifizierung untermauerte, forschungsgetriebene Lösungen bieten Präzision, Effizienz und unübertroffenes Service weltweit.

Kontaktinformationen

-

E-Mail

[email protected] -

Telefon

8618562586815 -

Adresse

Fabrik in Chengyang: Huida Straße, Shuangyuan Straße, Flughafen Industriegebiet, Chengyang Bezirk, Qingdao Stadt, Shandong Provinz, China.