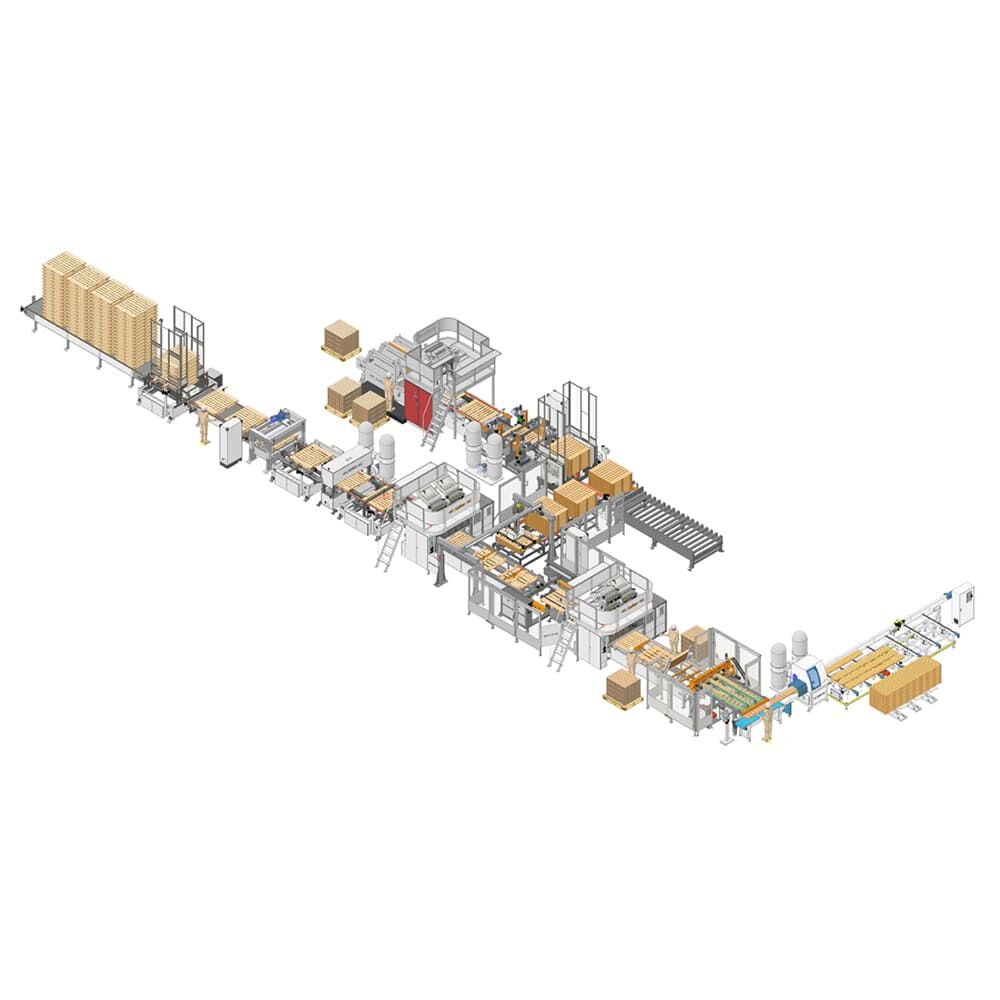

HICAS ofrece máquinas de alta calidad para hacer pallets de madera, personalizadas con 25 años de experiencia global. Apoyadas por certificaciones ISO9001, UL y CE, nuestras soluciones impulsadas por I+D ofrecen precisión, eficiencia y un servicio incomparable en todo el mundo.

Información de contacto

-

Correo electrónico

[email protected] -

Teléfono

8618562586815 -

Dirección

Fábrica en Chengyang: Huida Road, Shuangyuan Road, Área Industrial del Aeropuerto, Distrito de Chengyang, Ciudad de Qingdao, Provincia de Shandong, China.