Advantages of Spray Painting Machine

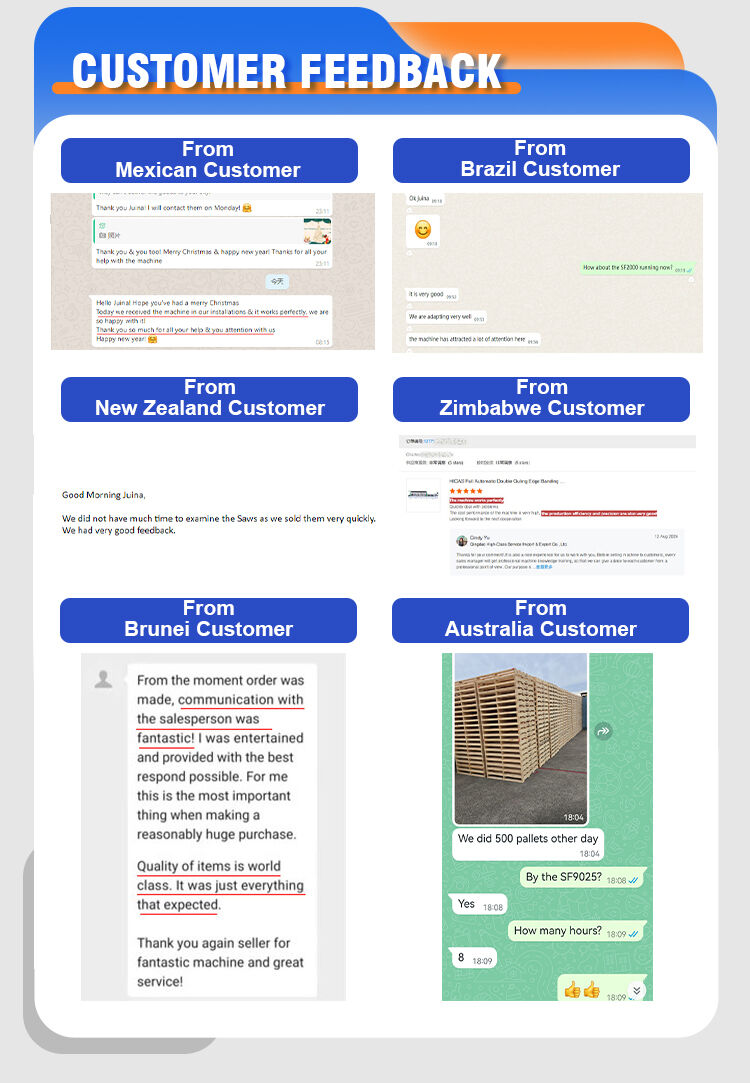

1. This 2.2KW explosion proof automatic spray painting machine adopts a fully enclosed spray booth design, and the front tempered glass door is easy to open.

2. It adopts an Italian flat-top compressed air filtration system, equipped with a filter fan, continuously replenishes clean air volume, and installs an exhaust gas filtration system.

3. The large-flow high-pressure fan ensures that the paint mist is completely recovered to avoid secondary pollution of the paint mist.

4. Equipped with a paint exhaust treatment cabinet to reduce environmental pollution.

5. The paint recovery system uses an independent recovery vehicle to facilitate paint recovery, replacement and cleaning.

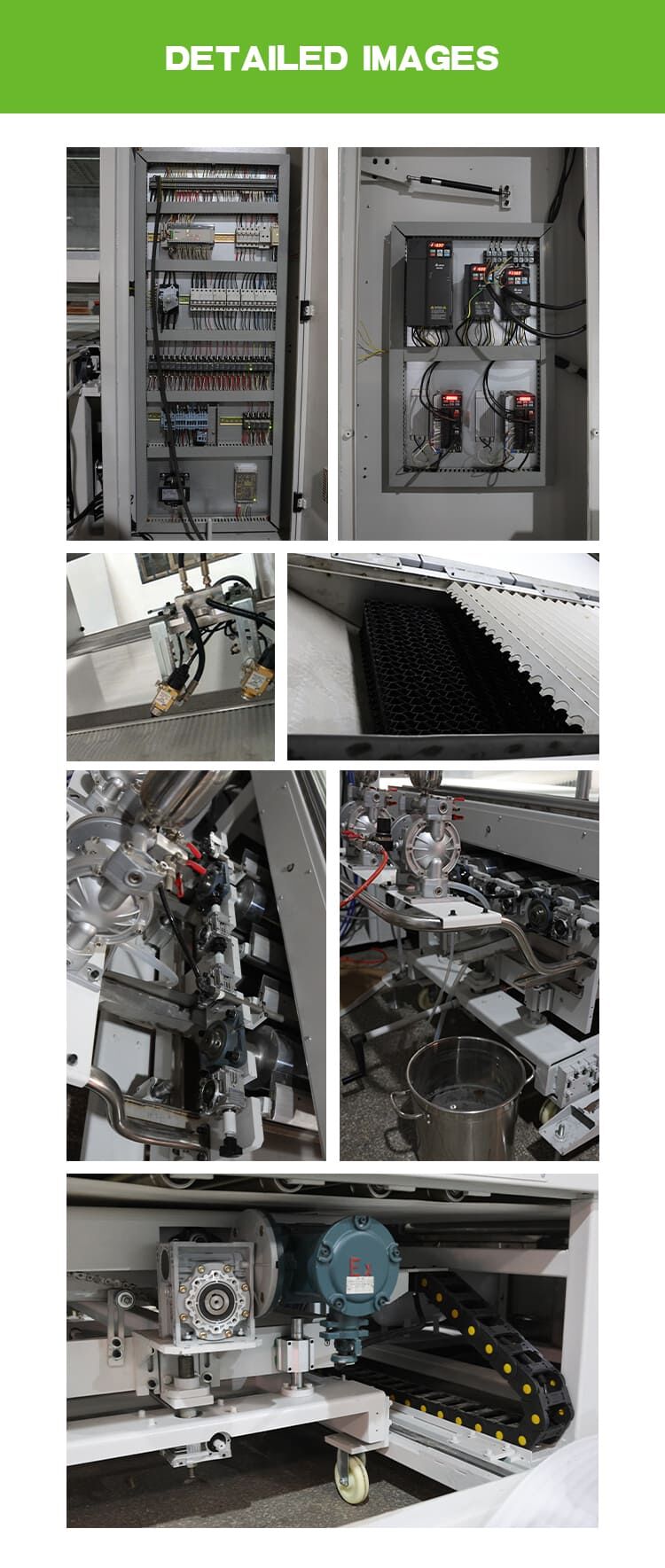

6. The control system uses an Italian imported grating to detect the feed port, and PLC programming controls the automatic spray gun action. Spraying is performed according to the shape of the workpiece to save paint to the greatest extent.

7. Equipped with an independent air pressure control system to accurately control the degree of automation of the spray gun, achieve the best automation effect, and reduce waste.

8. The human-computer interactive touch screen makes operation more convenient.