Main characteristic

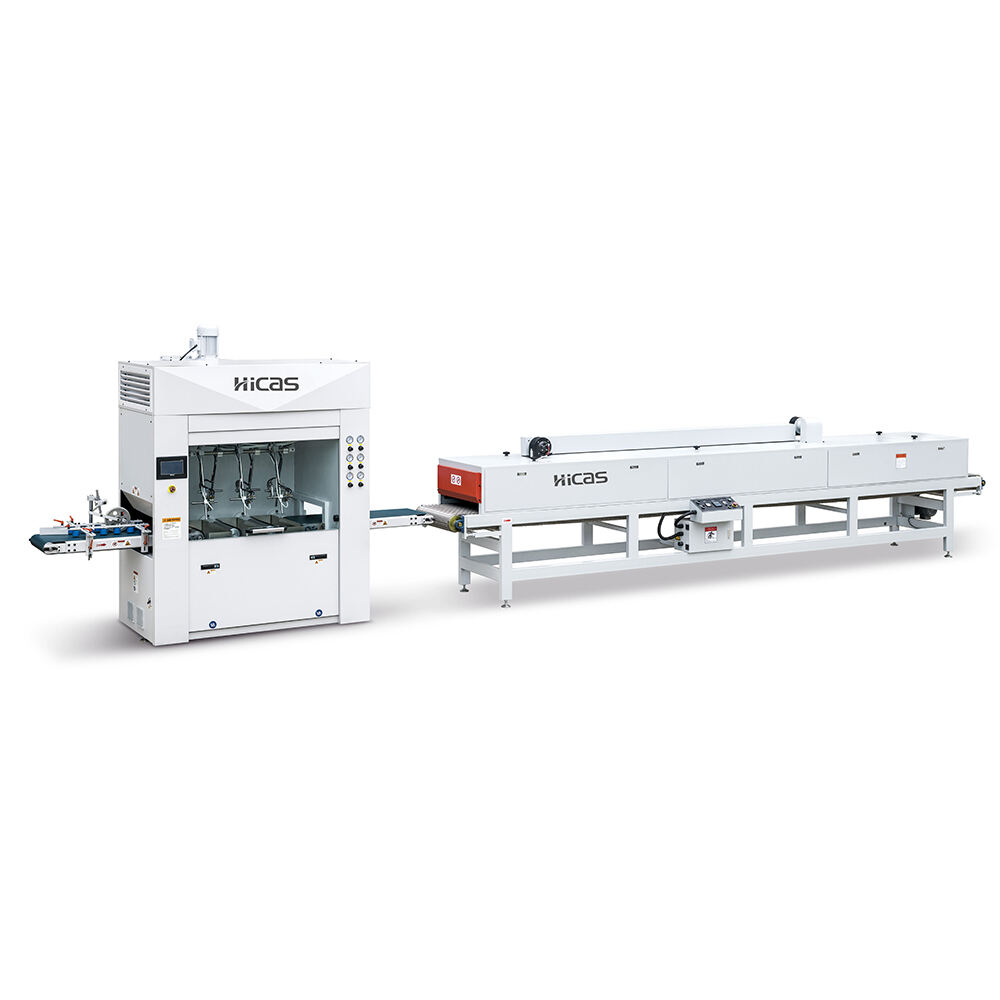

1. The rack is composed of square tubes and iron plates, with exquisite appearance and stable performance.

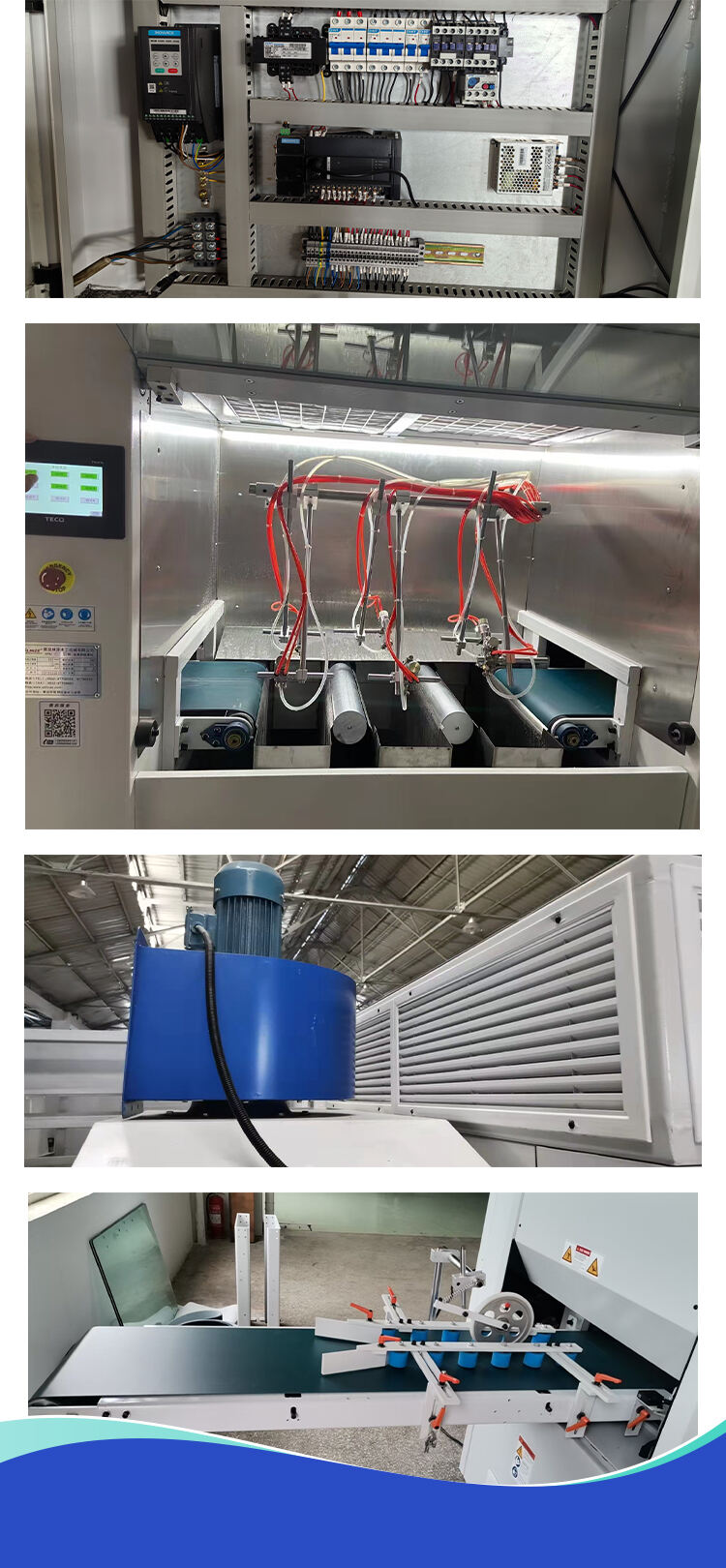

2. The machine configuration control system adopts 7-inch Taian PLC. Computer programs facilitate automated control.

3.The photoelectric induction system located at the machine inlet can accurately transmit the signal of the detected workpiece to the PLC program controller.

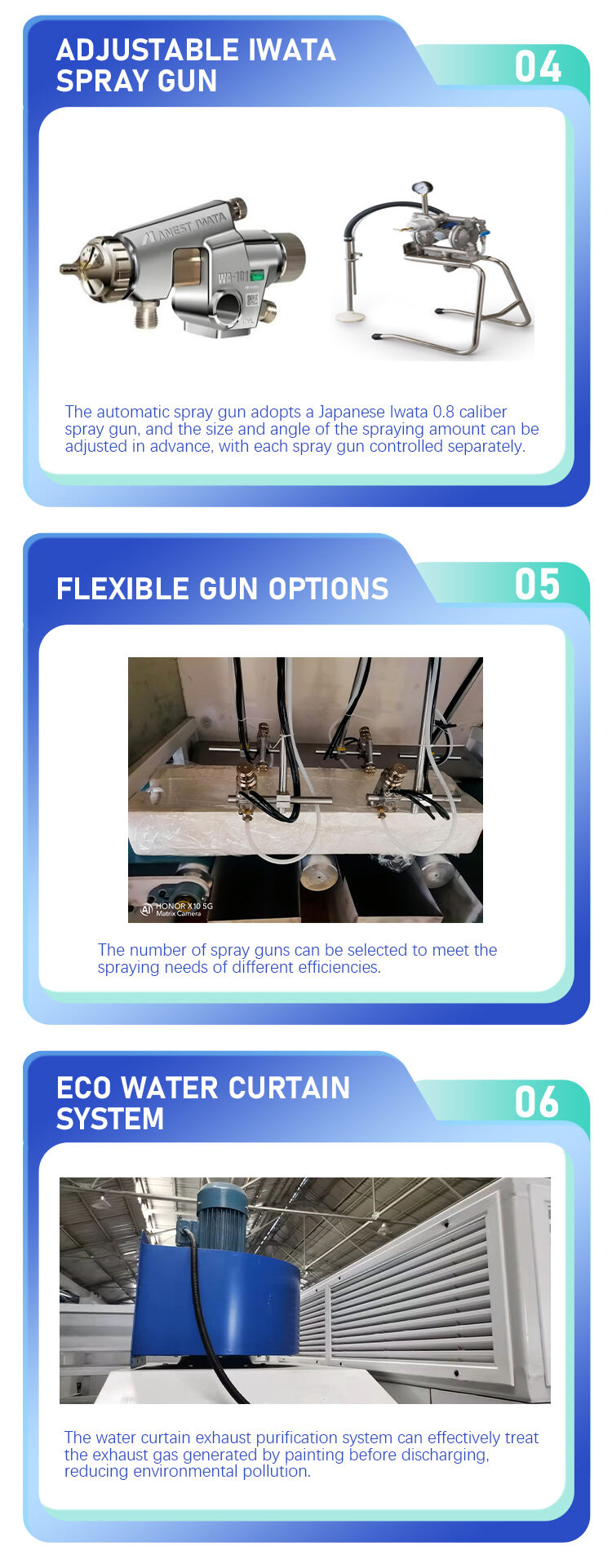

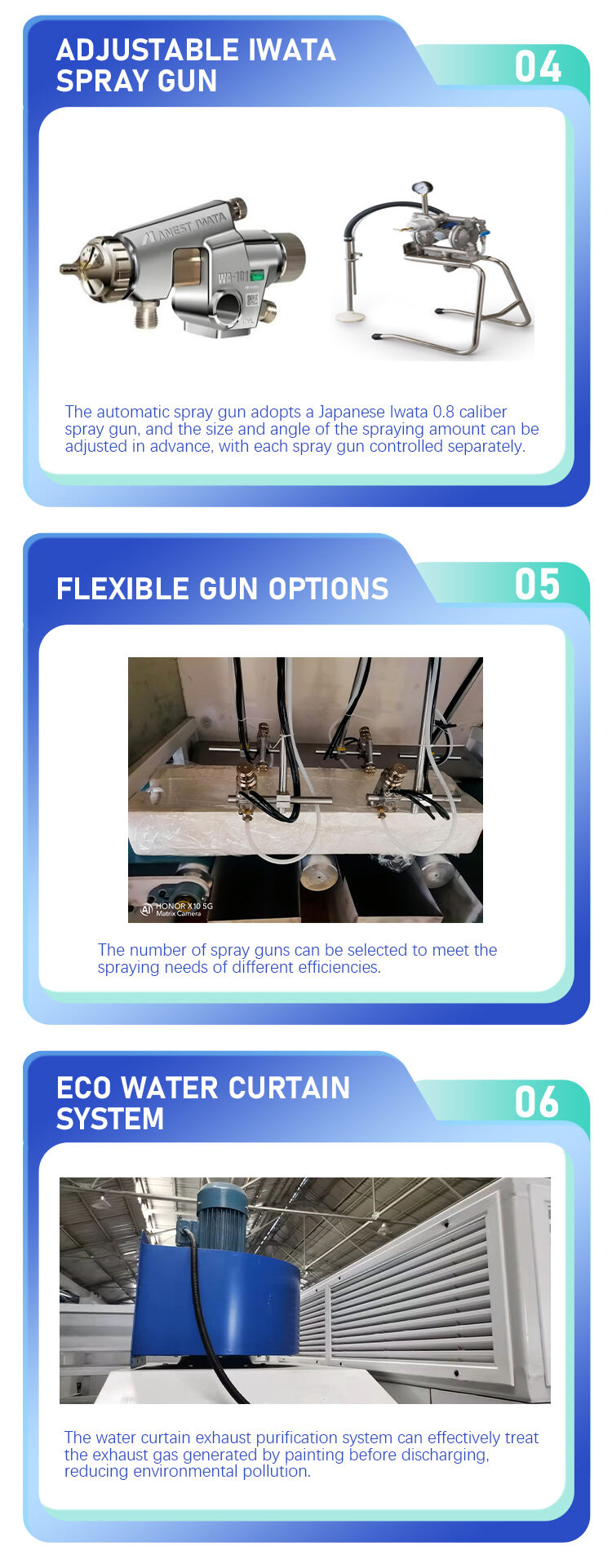

4. The automatic spray gun adopts a Japanese Iwata 0.8 caliber spray gun, and the size and angle of the spraying amount can be adjusted in advance, with each spray gun controlled separately.

5. The number of spray guns can be selected to meet the spraying needs of different efficiencies.

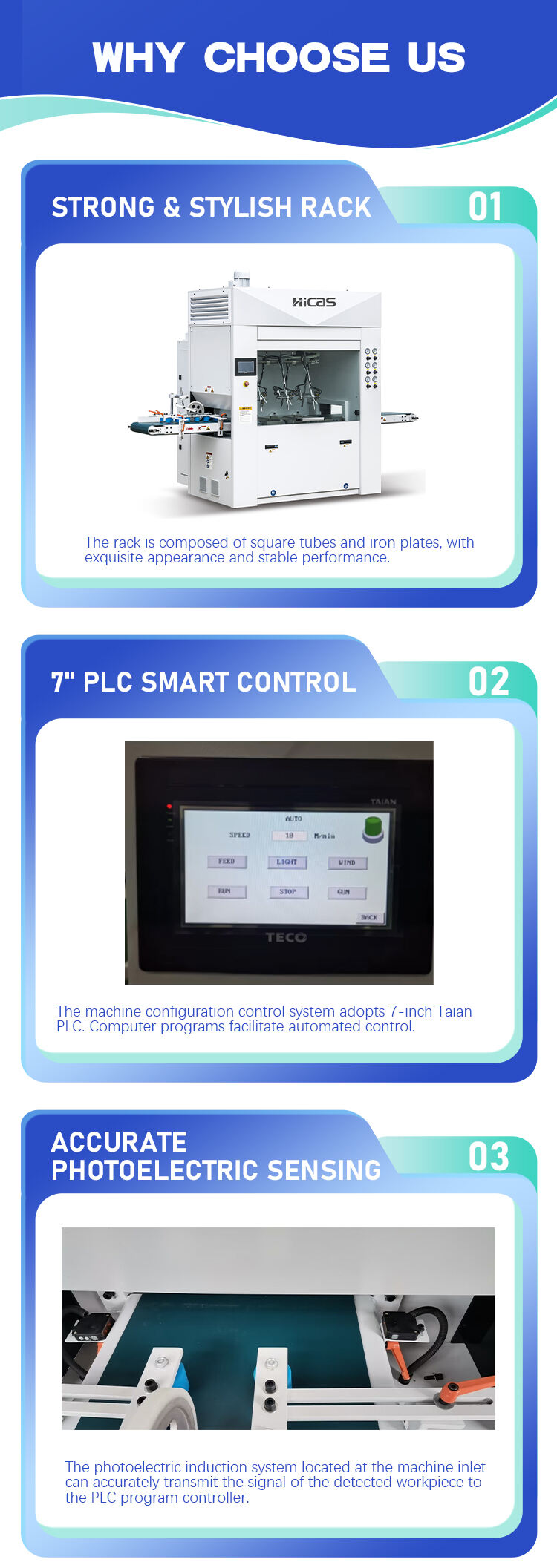

6. The water curtain exhaust purification system can effectively treat the exhaust gas generated by painting before discharging, reducing environmental pollution.

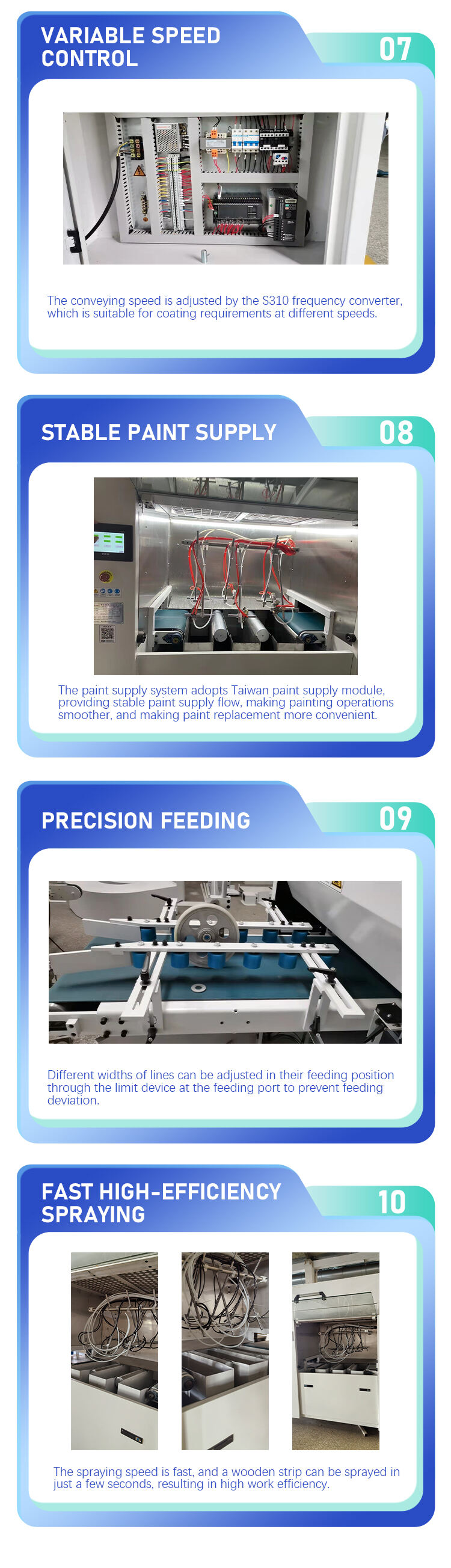

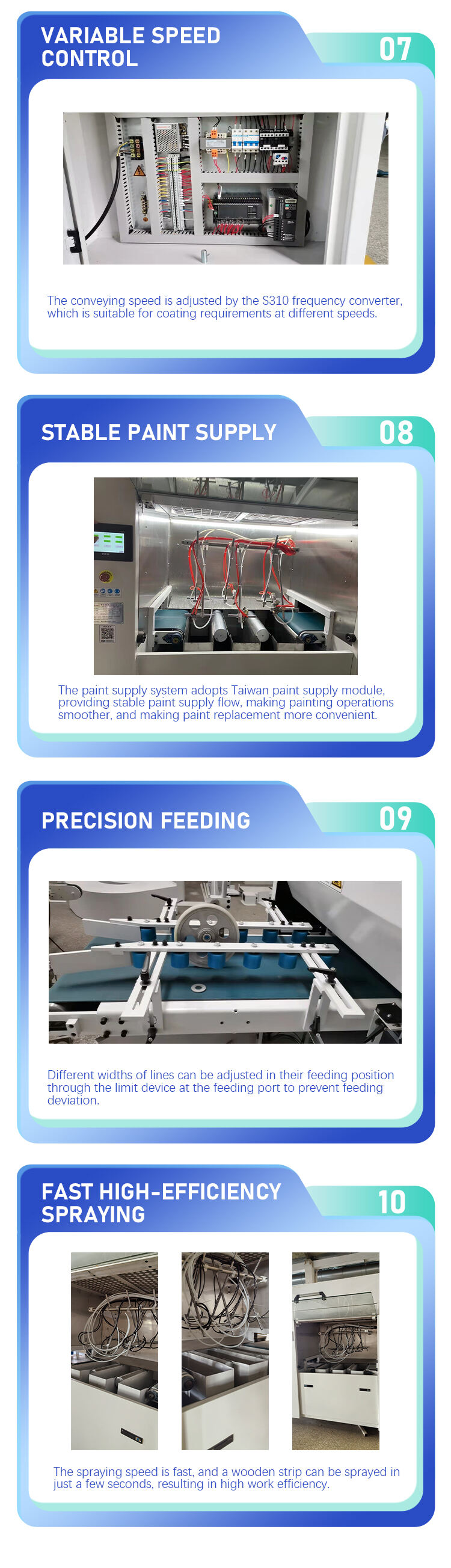

7. The conveying speed is adjusted by the S310 frequency converter, which is suitable for coating requirements at different speeds.

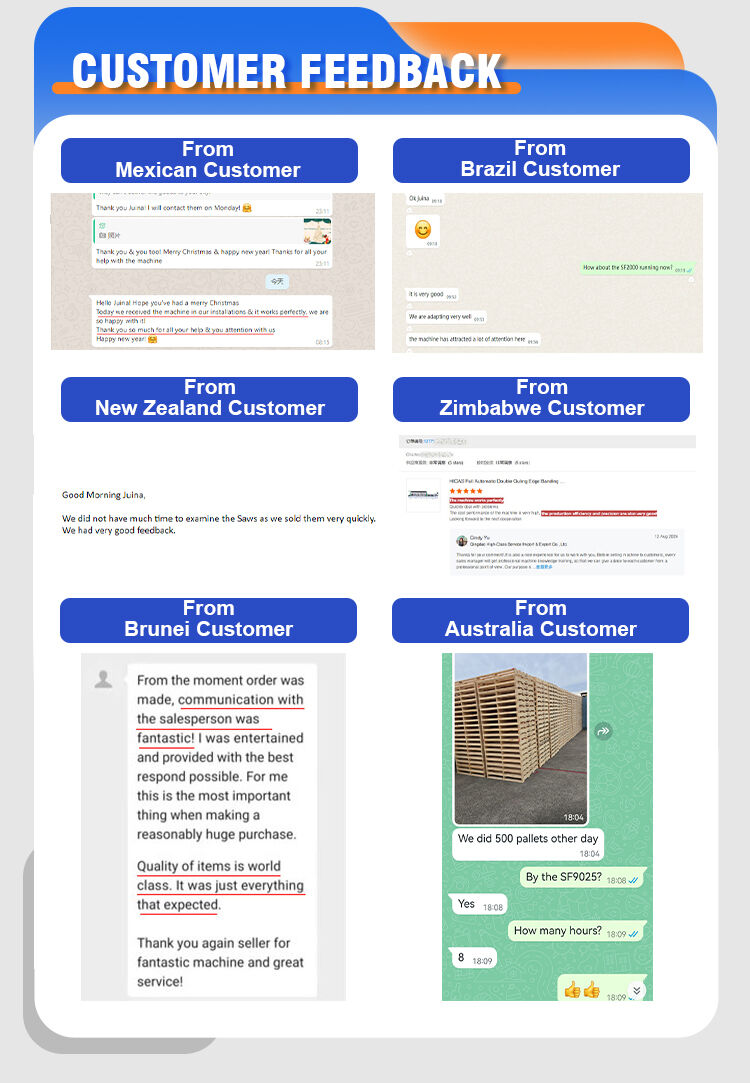

8. The paint supply system adopts Taiwan paint supply module, providing stable paint supply flow, making painting operations smoother, and making paint replacement more convenient.

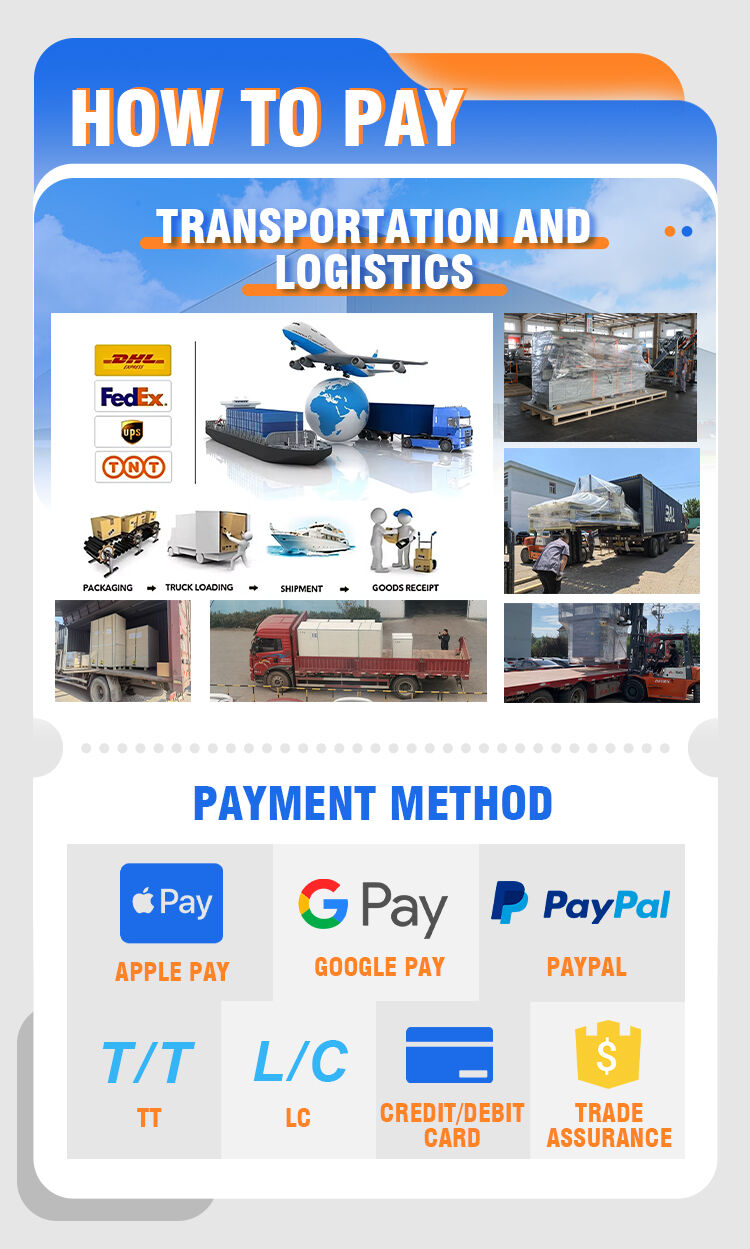

9. Different widths of lines can be adjusted in their feeding position through the limit device at the feeding port to prevent feeding deviation.

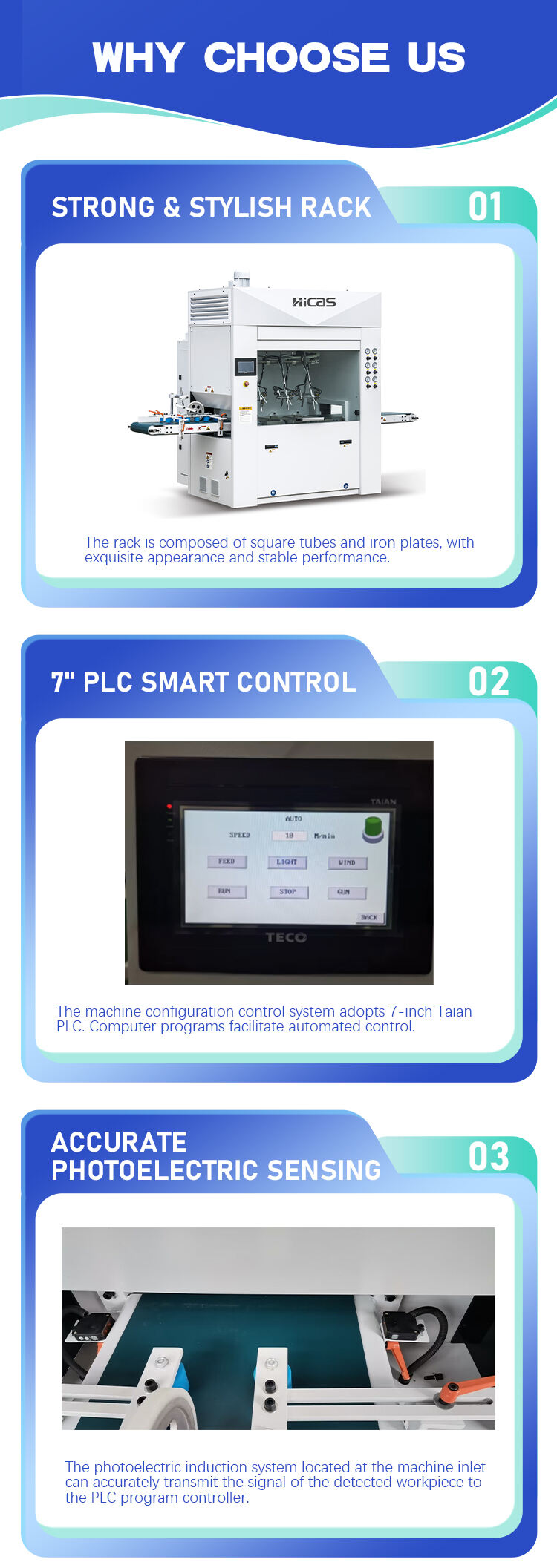

10. The spraying speed is fast, and a wooden strip can be sprayed in just a few seconds, resulting in high work efficiency.