Q:Do you offer installation? Video guidance and English manual can be provided freely, and we provide online support, now all ourA:customers install and operate the machine by themselves with our online support.

Q: Where can we get replacement parts?

A:Most of the spare parts are ready in stock. They will be sent to the buyer directly from our warehouse with original prices.

Q: How long can we get replacement parts?

A:Common spare parts can be delivered by express within one week. Some parts can be purchased locally.

Q: What technical support do you offer?

A:1. Technical support by phone, email or WhatsApp/Skype around the clock.

2. Friendly English version manual and operation video.

3. Engineer available to service machinery overseas.

Q:Do you have any machines in our country?

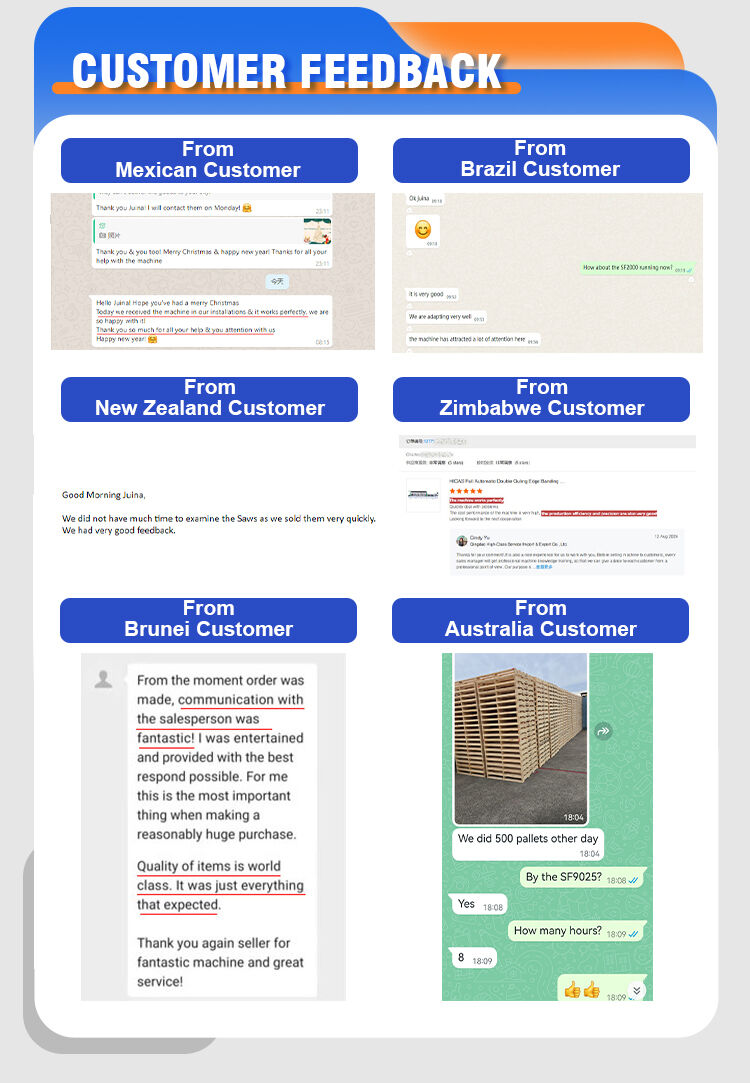

A:Our machines have been sold to more than 20 countries all over the world, like Russia, Singapore, Uzbekistan, The

USA,Malaysia,Peru, Colombia, Vietnam, Slovakia, etc.

Q:Can you customized the machine?

A:Our machines can be customized made according to buyers’ request.

Q:What other machine do you offer?

A:We provide one-stop shop service of woodworking machines for the buyers. Other kinds of woodworking machines, like sanding machine, CNC router, drilling machine, saw machine can be provided as well.

Q:Can you set the system to our language?

A:Our system supports common languages like Chinese, English, Russian, Spanish.