Advantages of SF4060 Automatic Wood Pallet Production Line

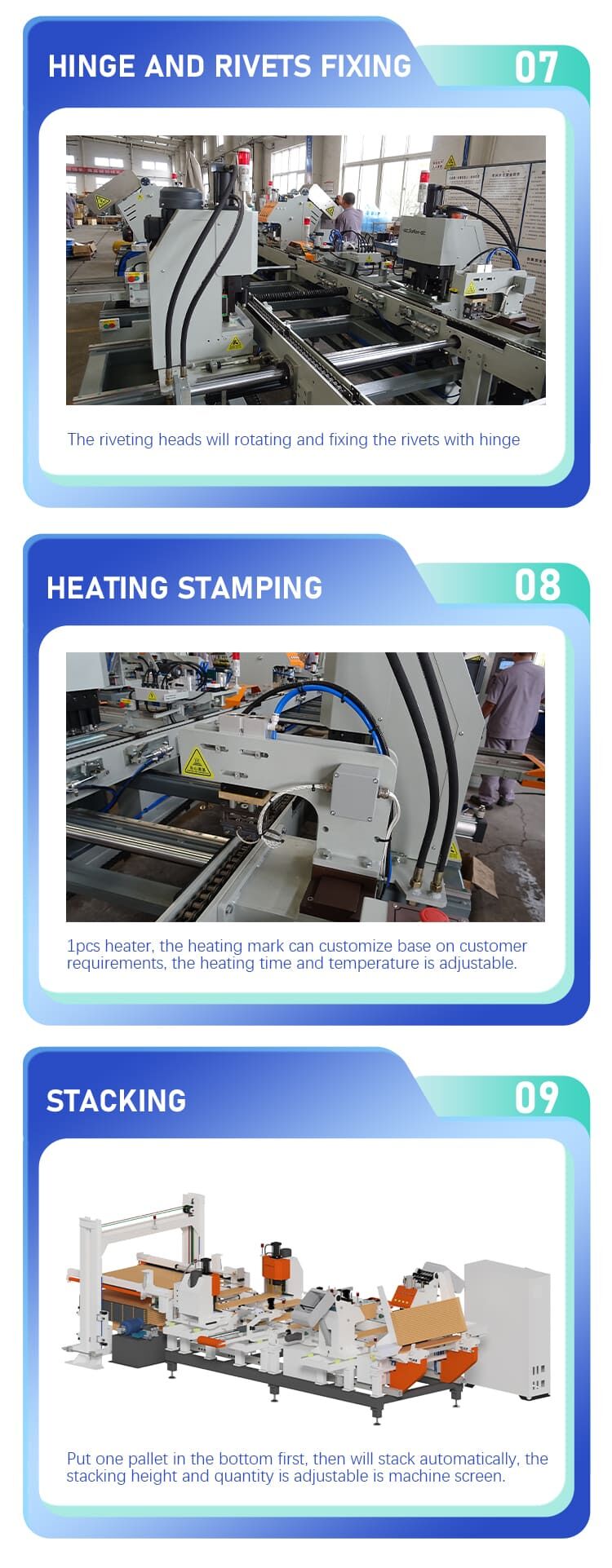

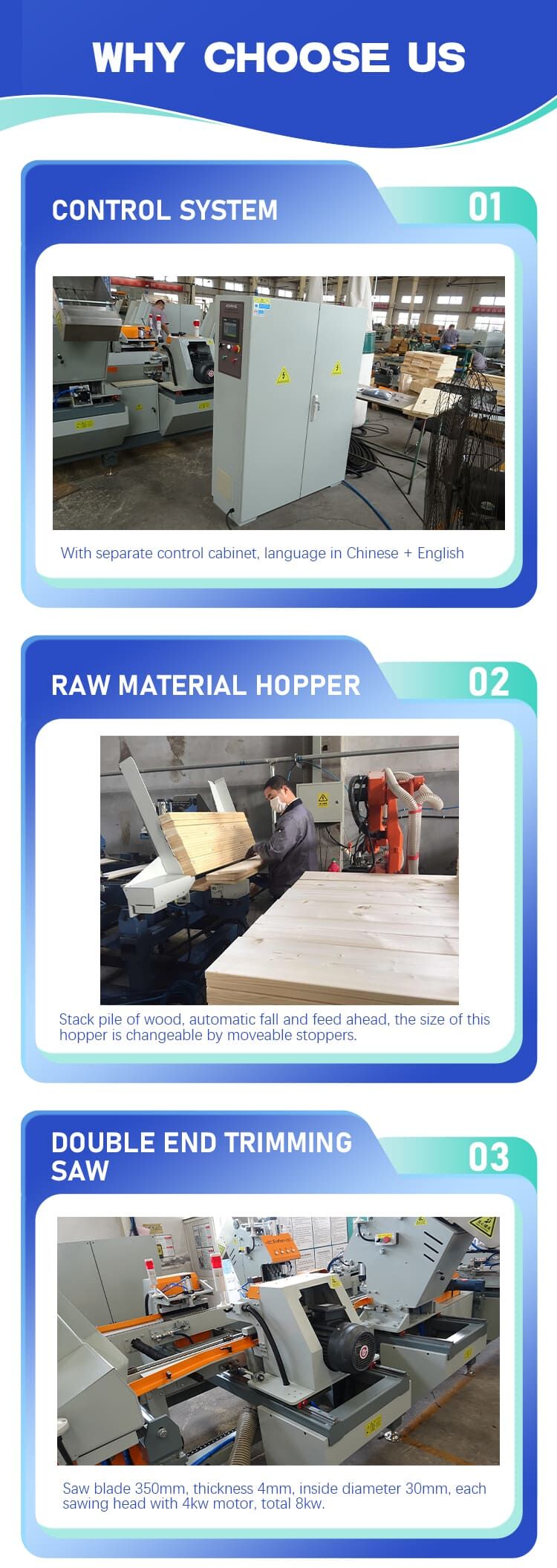

1. Control system

Equipped with independent control cabinet, Chinese + English language

2. Raw material hopper

Wood stacking, automatic material dropping and forward feeding, the hopper size can be adjusted by movable stopper.

3. Double-head trimming saw

Saw blade diameter 350 mm, thickness 4 mm, inner diameter 30 mm, each saw head is equipped with 4 kW motor, total power 8 kW.

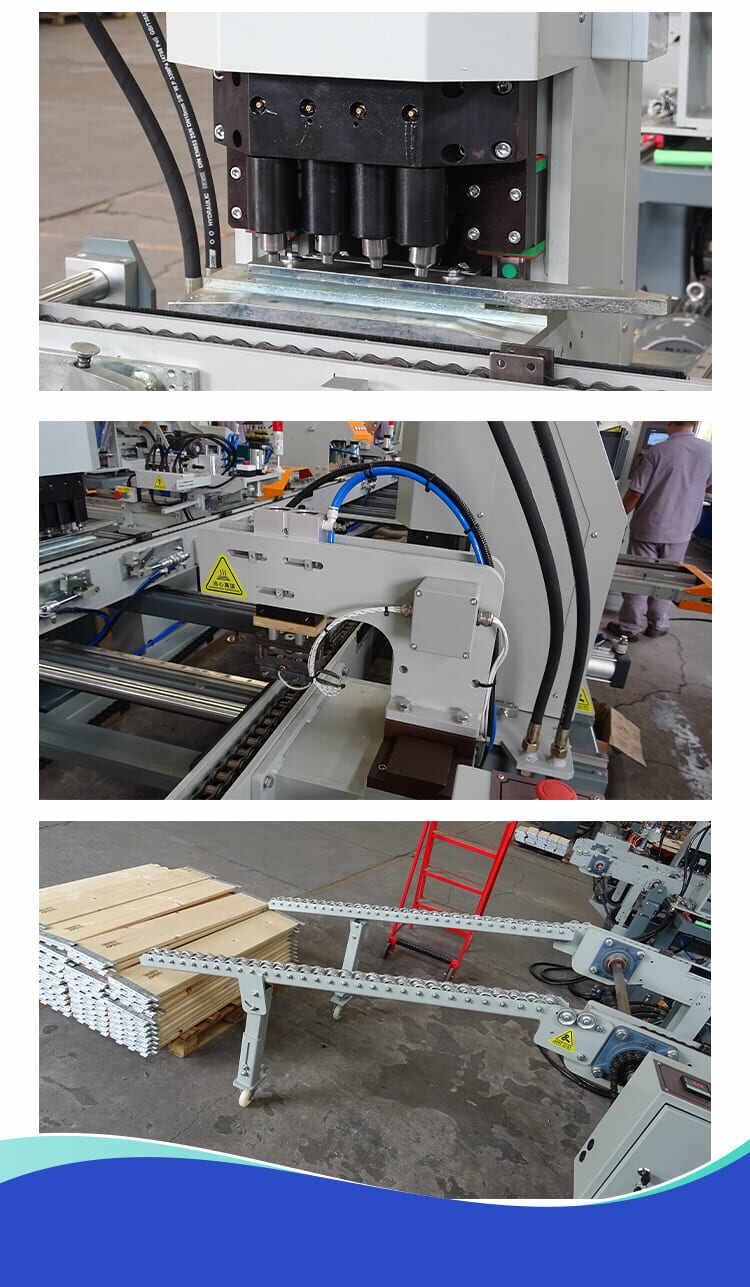

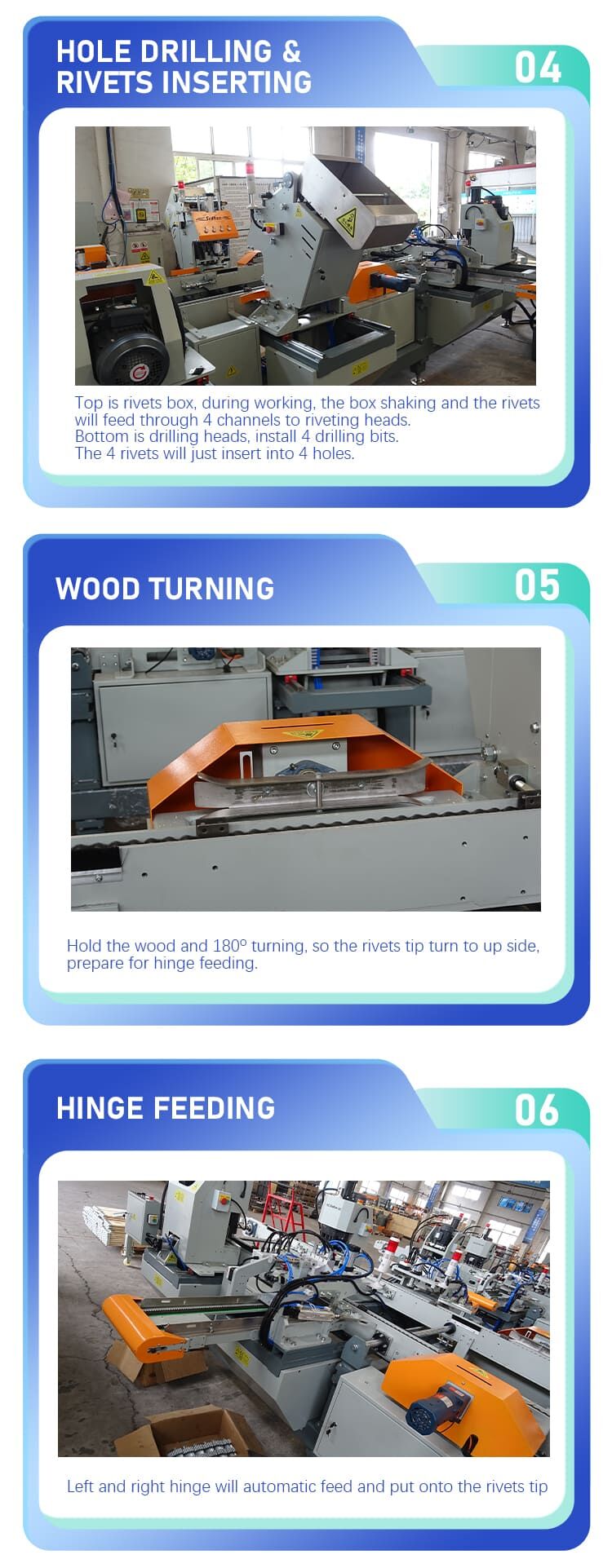

4. Drilling and rivet installation

The top is the rivet box, when working, the rivet box shakes, and the rivets are fed into the rivet head through 4 channels. The bottom is the drill, 4 drills are installed. 4 rivets are inserted into 4 holes exactly.

5. Wood turning

Hold the wood and rotate it 180° so that the rivet tip is facing up.

Ready to feed the hinge.

6. Hinge feeding

The left and right hinges are automatically fed and placed at the rivet tip.

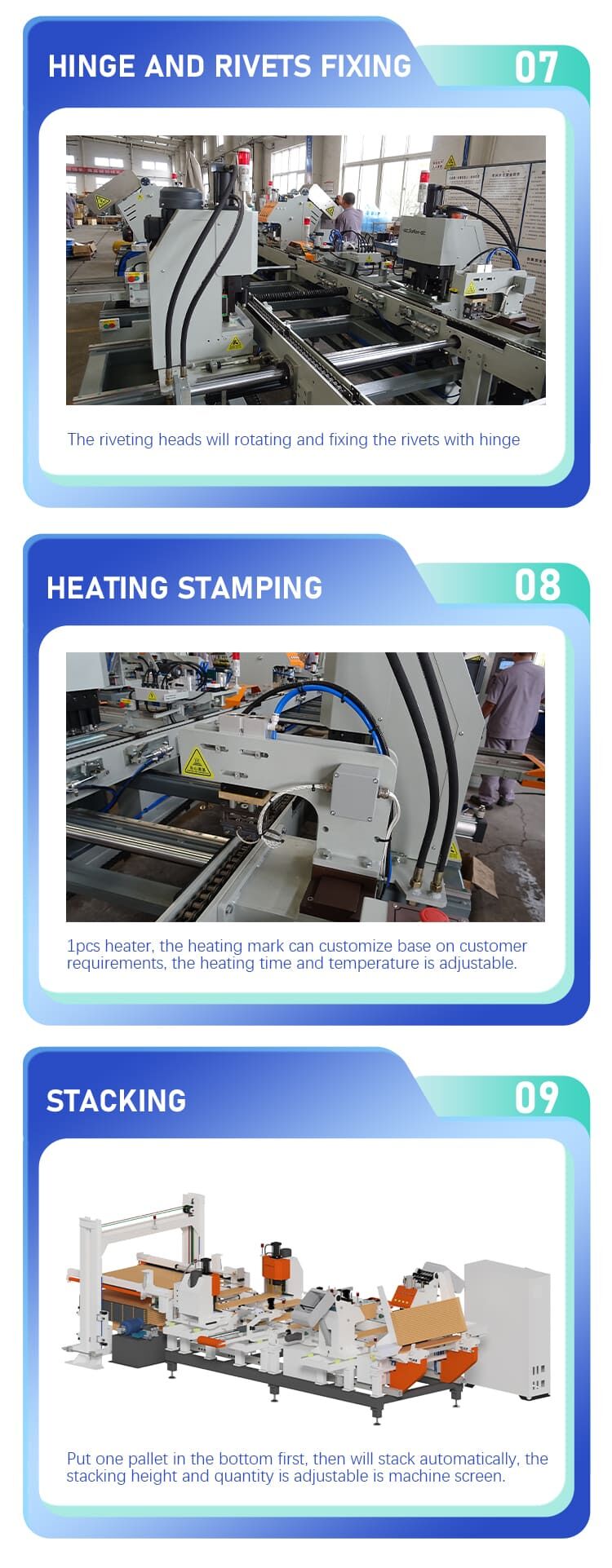

7. Hinge and rivet fixing

The rivet head rotates and fixes the rivet on the hinge.

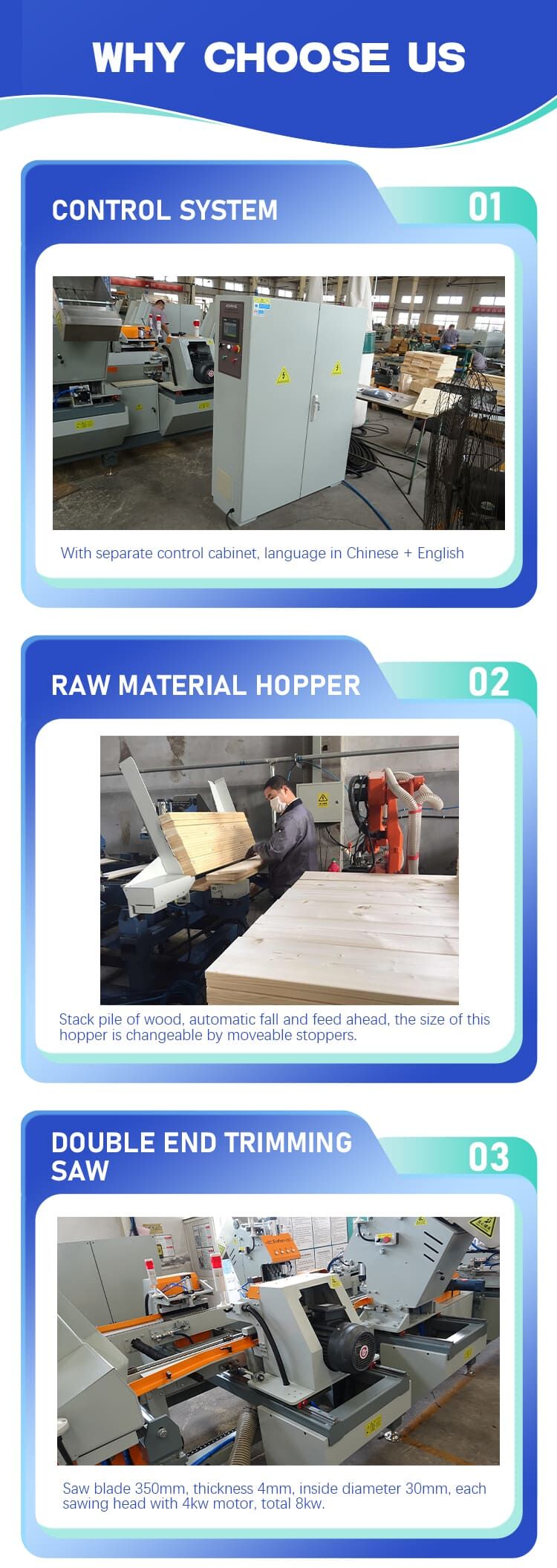

8. Heating stamping

1 heater, heating mark can be customized according to customer requirements, heating time and temperature are adjustable.

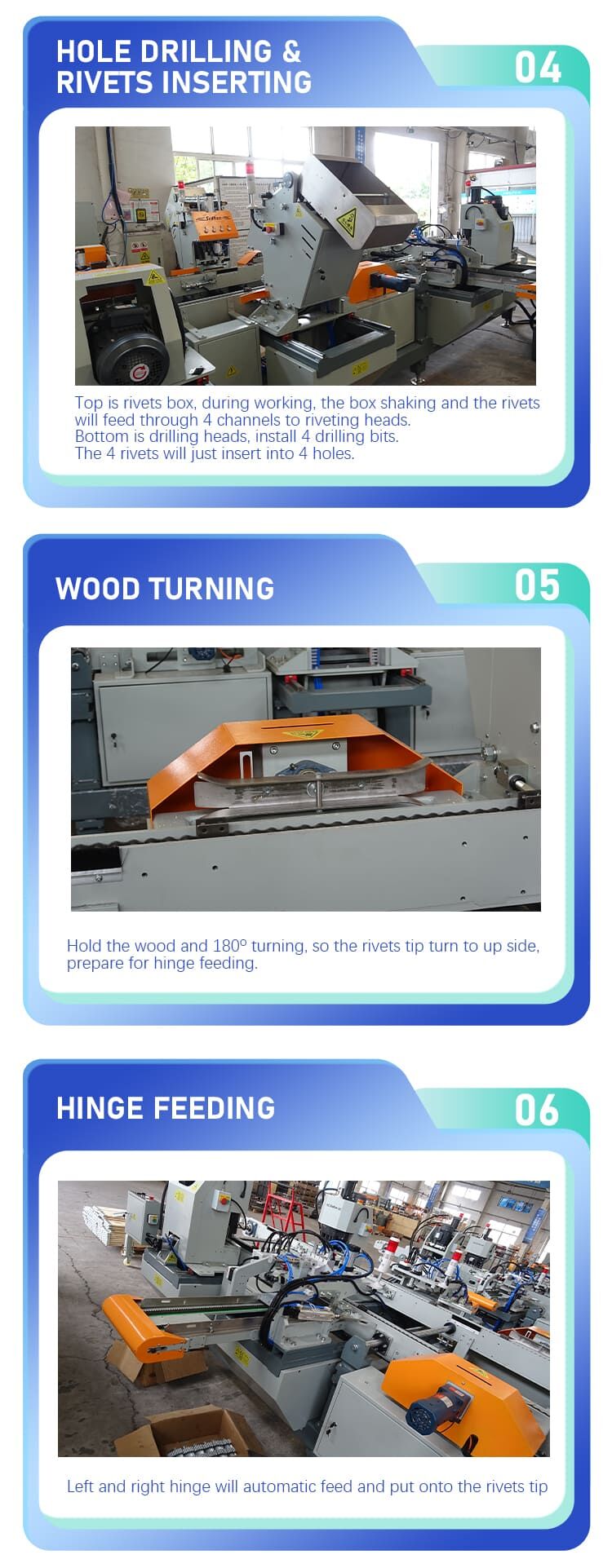

9. Palletizing

First place a pallet at the bottom, then automatically palletize, the palletizing height and quantity can be adjusted according to the machine screen.