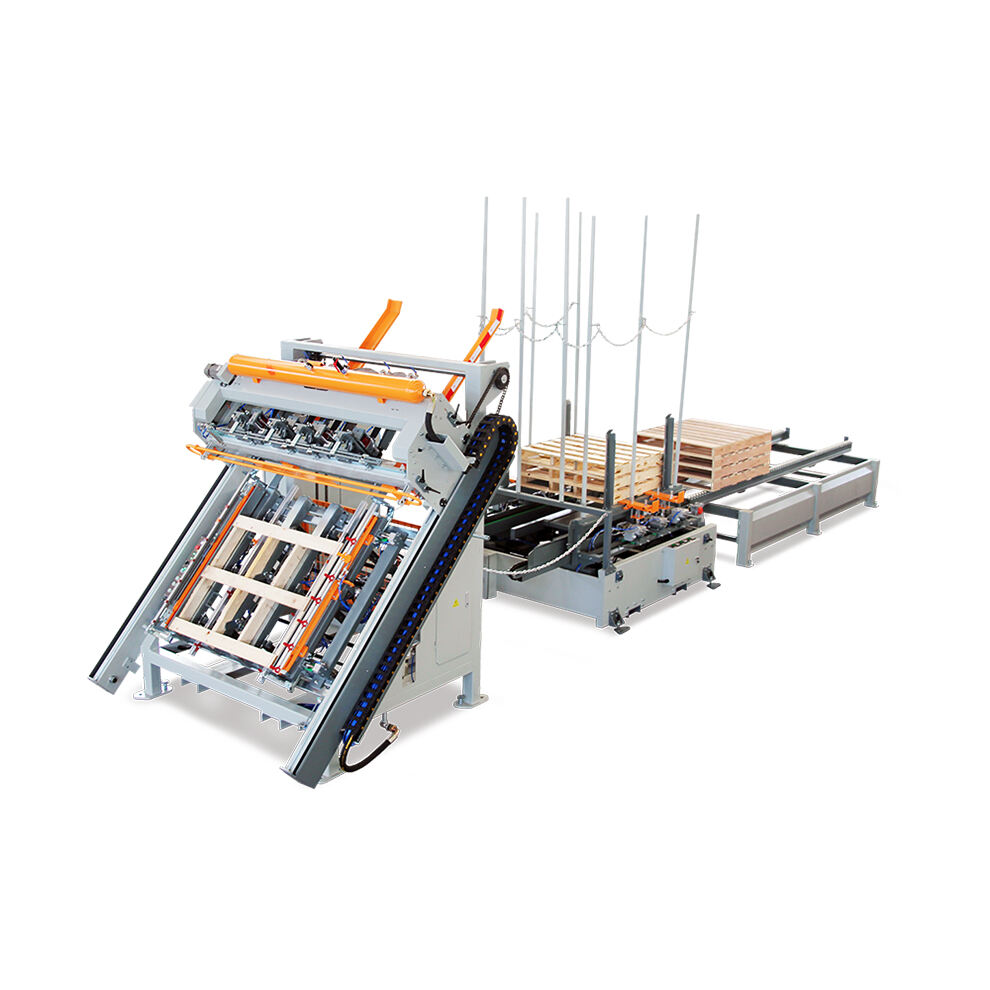

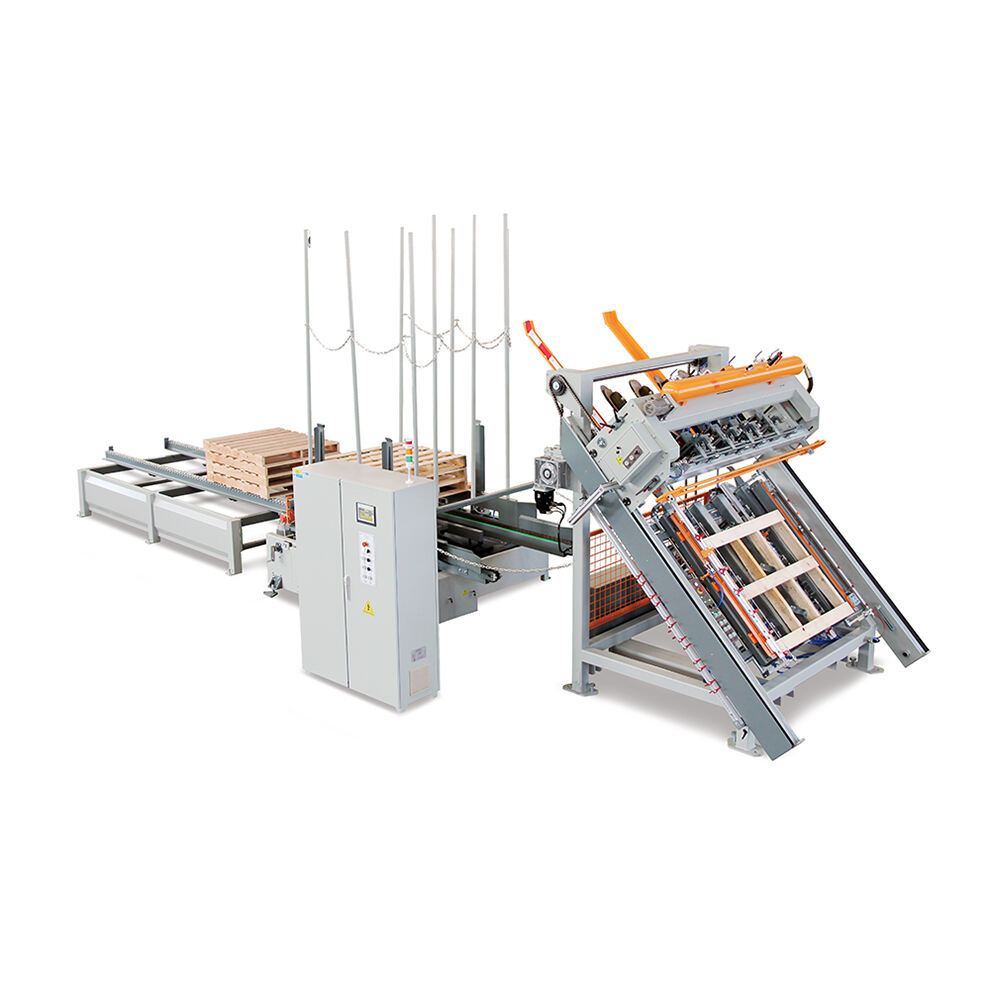

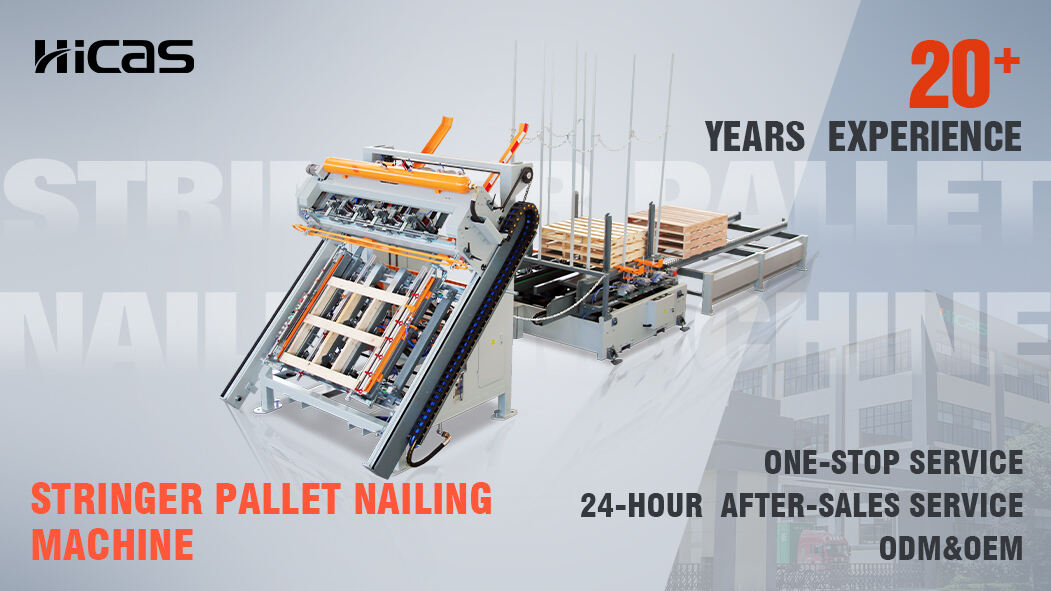

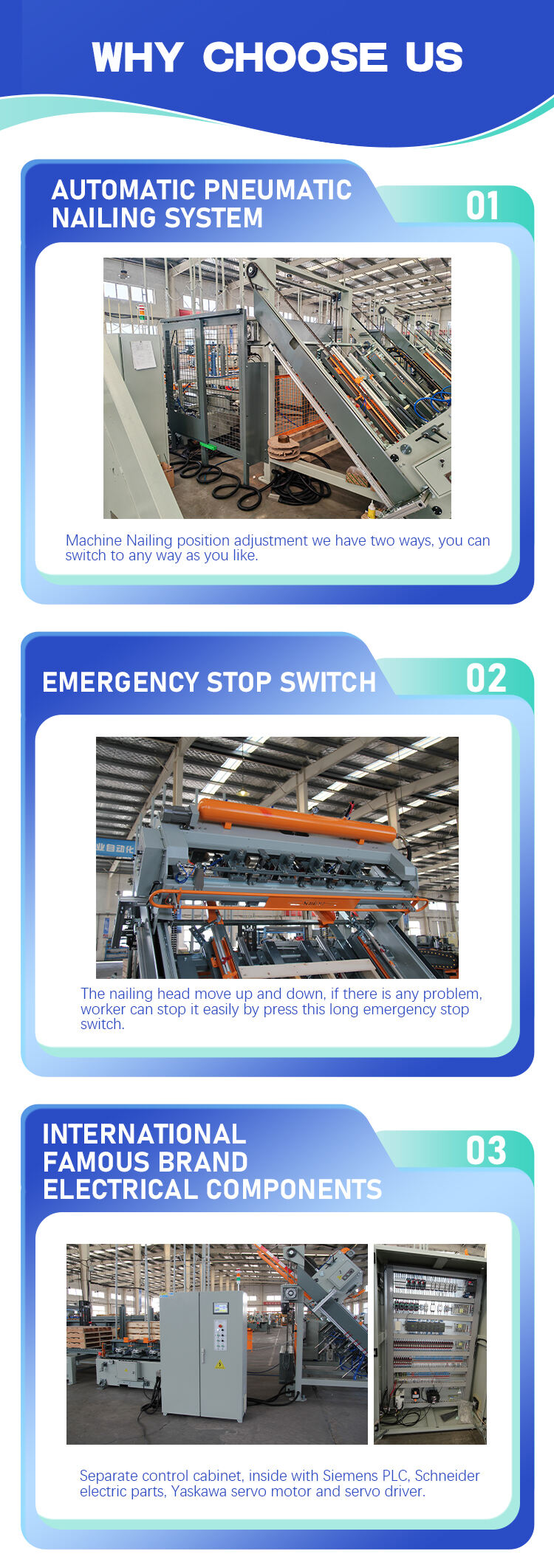

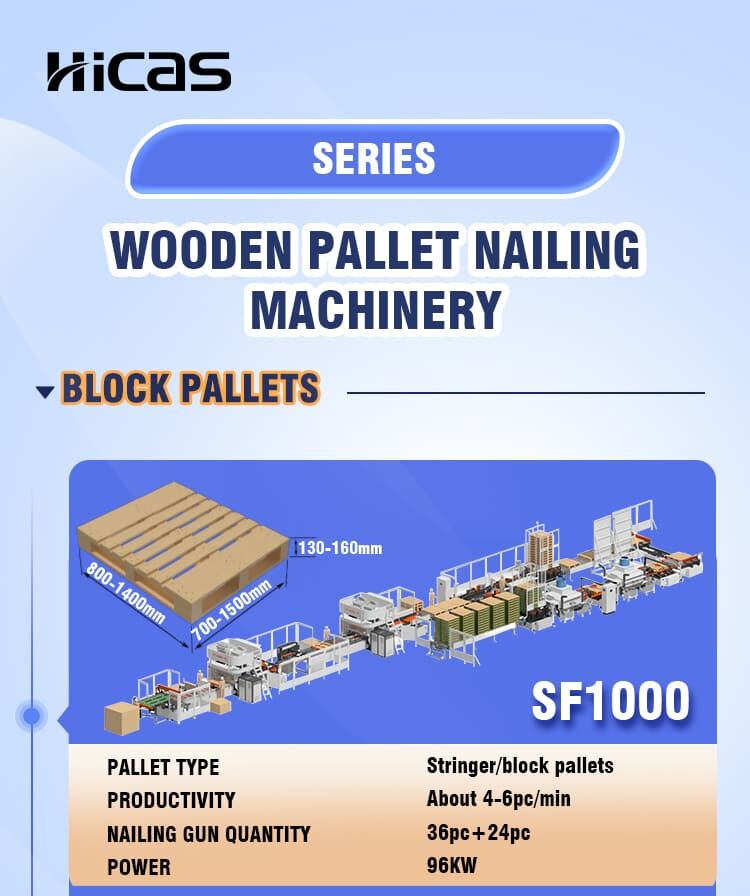

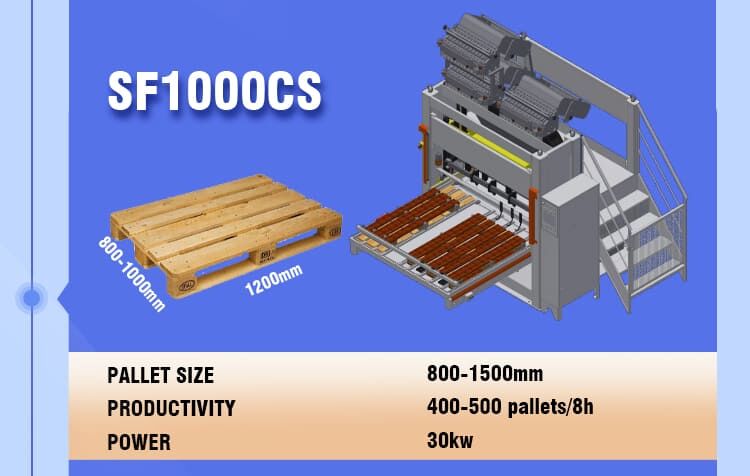

HICAS offers high-quality, customized wood pallet making machines with 25 years of global experience. Backed by ISO9001, UL, and CE certifications, our R&D-driven solutions deliver precision, efficiency, and unmatched service worldwide.

Contact Info

-

Email

[email protected] -

Phone

8618562586815 -

Address

Factory in Chengyang: Huida Road, Shuangyuan road Airport Industrial Area, Chengyang district, Qingdao city, Shandong province, China.