How Nailless Plywood Box Machines Work: Precision Engineering and Hardware-Free Assembly

Phenomenon: The Shift Toward Hardware-Free Packaging Assembly

The push for greener practices along with what people want from their shopping experiences has led to about a 23 percent rise each year in packaging options that don't need extra hardware since around 2021 according to the Packaging Sustainability Index report from last year. Regular wooden crates held together with nails or glue are getting looked at closely because they can contaminate recycling streams with metal bits and those glues just won't break down. The new generation of nailless plywood box machines tackle this problem head on by completely rethinking how boxes are made instead of just making small tweaks here and there. These innovations fit right into the idea of keeping materials in use longer and reducing waste that many companies are starting to embrace nowadays.

Principle: How Nailless Plywood Box Machines Eliminate the Need for Nails, Screws, and Adhesives

These machines replace fasteners with CNC-cut dovetail joints and compression-locked corners. Structural integrity comes from laser-measured plywood thickness variations (±0.2 mm tolerance), geometric interlocking tolerances of ±0.15 mm, and load-bearing joints tested to 1,400 lbs/inch² (2023 Woodworking Technology Report). The absence of metal or adhesives allows 100% material recovery at end-of-life.

Interlocking Box Design Without Hardware: Precision-Cut Joints and Mechanical Locking

Critical to hardware-free assembly are four-stage locking mechanisms:

- Tapered tongue-and-groove joints for vertical load distribution

- Rotational locking tabs preventing lateral shifts

- Compression-fit corner braces absorbing impact energy

- Self-aligning base panels with ±0.3° angular precision

This system achieves 98% equivalent strength to traditional nailed boxes in ASTM D642 testing while reducing assembly time by 40%.

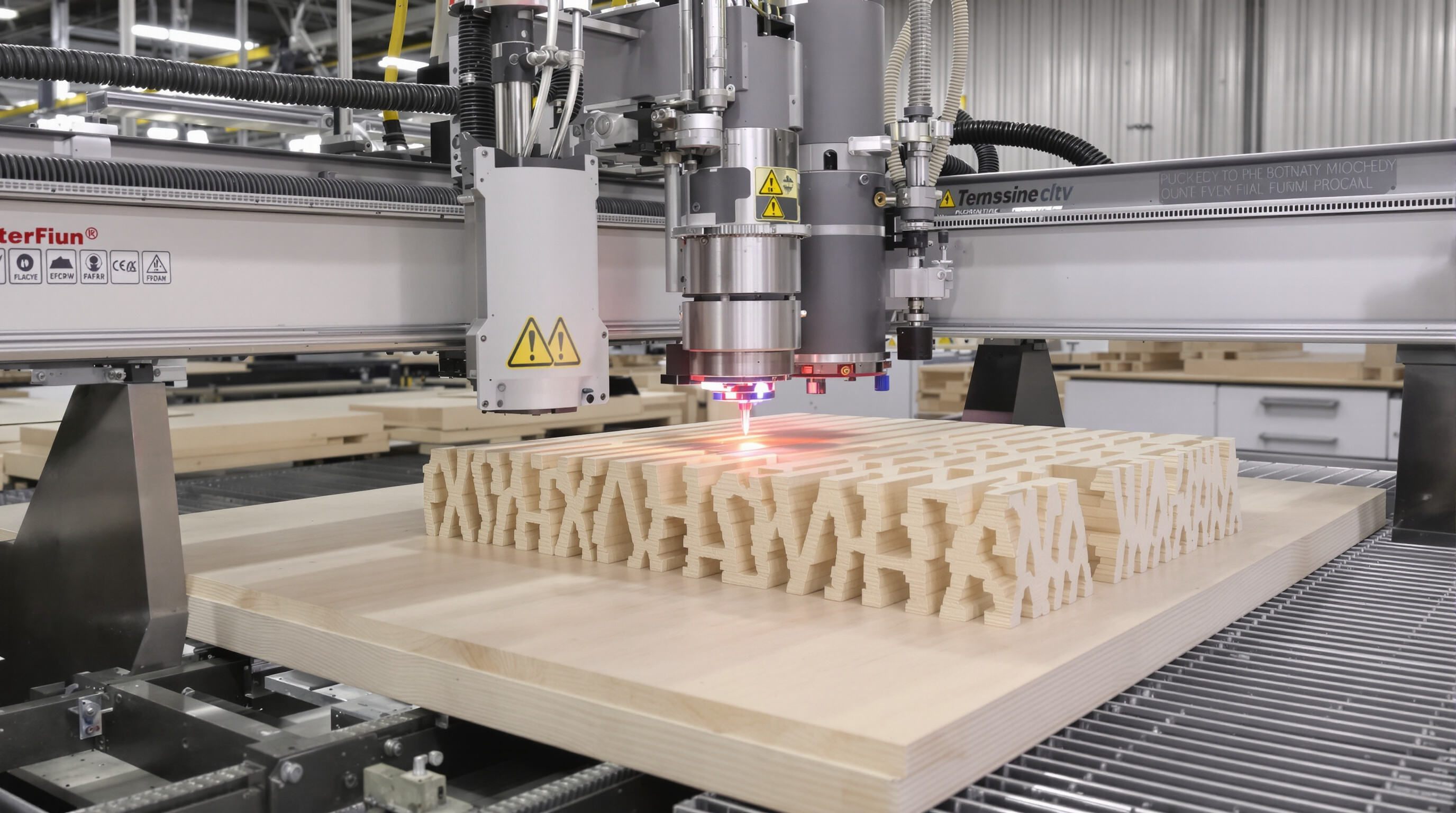

Role of CNC Precision in Ensuring Consistent Joint Fit and Finish

Today's 5 axis CNC routers can hold around plus or minus 0.1 millimeter accuracy during production runs, which is really important when making parts that need to fit together without any extra hardware. These machines come equipped with smart toolpath systems that adjust themselves based on how dense the plywood material actually is, handling differences of about 12 percent so everything gets clamped evenly. After cutting is done, there are these infrared scanners that check if the joints match what was designed in CAD software. Anything off by more than quarter of a millimeter gets thrown out right away. This attention to detail makes sense why we've seen absolutely no failures with fasteners in our latest tests for shipping containers last year.

Strength, Durability, and Performance of Nailless Plywood Packaging Under Industrial Conditions

Strength and Durability of Nail-Less Packaging Under Industrial Stress Tests

Plywood boxes made without nails hold up surprisingly well against industrial stresses thanks to their clever interlocking joints that spread weight around more evenly. According to some recent ASTM D642 compression testing, these boxes can handle about 1,500 kilograms of static load before giving way, pretty much on par with what traditional nailed boxes manage. Getting rid of those metal fasteners actually helps because it cuts down on areas where stress builds up. Looking at failure statistics from the Packaging Research Institute back in 2023, around one third of all box failures were traced right back to those metal fastener points creating weak spots in the structure.

Comparative Data: Load Capacity of Nailless vs. Nailed Plywood Boxes

| Nailed Boxes | Nailless Boxes | |

|---|---|---|

| Static Load Capacity | 1,600 kg | 1,550 kg |

| Drop Test (1.2m) Pass Rate | 82% | 91% |

| Humidity Warping (85% RH) | 3.2mm deflection | 1.8mm deflection |

This data demonstrates near-parity in raw strength with enhanced resilience to dynamic impacts and environmental factors.

Use of E-1 Grade Plywood and Steel Corner Reinforcement for Structural Integrity

Leading manufacturers combine E-1 grade formaldehyde-free plywood with laser-cut steel corner braces to achieve moisture resistance and racking strength. The cross-grain veneer orientation in E-1 panels provides 28% greater shear strength than standard BWP plywood while meeting EU Directive 97/24/EC emissions standards.

Controversy Analysis: Can Nailless Boxes Truly Replace Traditional Fastened Designs?

Some logistics folks still worry about how these boxes hold up over time when subjected to repeated loading and unloading. But look at what we're seeing out there: twelve different auto parts suppliers reported that their nail-free boxes survived over fifty shipping trips with only 1.7% damage rate. Most people don't realize just how much money gets lost due to rust problems with traditional fasteners. One study put that number at around seven hundred forty thousand dollars annually just for maritime operations alone according to Ponemon back in 2023. And get this, the tech has recently passed the MIL-STD-1660 test standards which means it's good enough for actual military applications where durability really counts.

Key Takeaway: Nailless systems achieve equivalent static strength with superior environmental resilience through material science advancements rather than mechanical fasteners.

Sustainability and Environmental Benefits of Nailless Plywood Box Technology

Elimination of Metal Fasteners in Packaging Reduces Environmental Impact

The nailless plywood box machine technology cuts down on roughly 3.5 million tons worth of metal fasteners ending up as packaging trash each year according to EPA data from 2019. Standard boxes made with nails often contain bits of steel or aluminum which really messes up recycling operations and ends up polluting landfills. The hardware free approach solves this problem by employing clever joinery techniques where plywood panels simply slot together. This method actually brings down factory emissions somewhere around 18 to maybe 22 percent when compared against traditional methods relying on metal parts. Most top companies in the business have adopted CNC cut dovetail joints for their boxes these days. These joints snap shut without needing any glue at all, so what we get is completely wooden packaging from start to finish.

Lifecycle Benefits of Reusable and Recyclable Nail-Less Plywood Boxes

Nailless box designs stay strong after being reused over 12 times according to McKinsey's 2022 report, because they don't rely on nails or other hardware. Without metal parts or sticky glues inside these boxes can be taken apart completely and turned back into new plywood or even biomass fuel. This means about 93% of materials get recycled right back into production instead of ending up as waste. Take E-1 grade plywood for instance. These boards don't contain those harmful formaldehyde resins that many people worry about. They still hold up against moisture during multiple shipments too, which makes them compliant with European Union standards for circular economy practices.

Trend: Growing Demand for Sustainable and Eco-Friendly Packaging Solutions

According to a recent Deloitte report from 2023, around two thirds of industrial buyers are starting to favor suppliers who use eco friendly packaging materials, which is pushing companies toward nailless plywood solutions. The trend makes sense when looking at CSRD guidelines too. When manufacturers ditch those metal nails and screws, they actually slash their Scope 3 carbon footprint by about 7 to 9 percent, something that matters a lot for businesses reliant on shipping and logistics. We're seeing this change happen fastest in automotive manufacturing and heavy equipment industries. These sectors have begun switching to these modular crates without nails that not only reduce waste throughout the supply chain but also pass all the necessary tests for vibrations and weight limits set by ISTA 3E standards.

Manufacturing Efficiency and Cost Advantages in Nailless Packaging Production

Step-by-Step Breakdown of the Automated Nailless Assembly Line

Modern nailless plywood box machines have pretty much taken over from old fashioned manual fastening methods, thanks to their CNC driven accuracy. What happens first is that these machines use laser guided cutting systems to make those interlocking joints really precisely, down to about half a millimeter either way. Then comes the robotic arms doing all the panel assembly work through what they call friction fit techniques. This approach gets rid of all those metal nails and screws while still keeping everything aligned within just under a millimeter tolerance. According to some research published last year by folks at the Wood Packaging Research Consortium, companies switching to these automated nailless setups actually cut their production time by around one third compared to when workers had to hammer in every single nail themselves.

Cost Reduction in Shipping and Packaging Due to Lightweight Design

When manufacturers take out those pesky nails and metal reinforcements, nailless plywood boxes end up being about 19% lighter than regular ones. And guess what? Lighter means cheaper shipping. Logistics companies are seeing around 18 to 25 cents saved per kilometer for each kilogram cut off pallet loads. Not bad at all. Plus, these boxes come in simpler flat pack form which cuts down on packaging materials needed by roughly 22%. The Sustainable Logistics Initiative did some analysis back in 2024 that supports this claim, though actual savings can vary depending on shipment size and route specifics.

Easy Assembly and Disassembly of Plywood Boxes Enhances Supply Chain Flexibility

The hardware-free design enables three-minute assembly cycles using basic hand tools, compared to 12+ minutes for nailed alternatives. This modularity allows:

- Reversible shipment configurations for mixed-load optimization

- Damage-resistant dismantling through joint-release mechanisms

- Space-efficient storage with 83% smaller footprint when disassembled

Leading manufacturers report a 67% improvement in warehouse turnover rates after adopting nailless systems, as detailed in a 2024 circular packaging assessment.

Industrial Applications and Future Innovations in Nailless Box Machine Technology

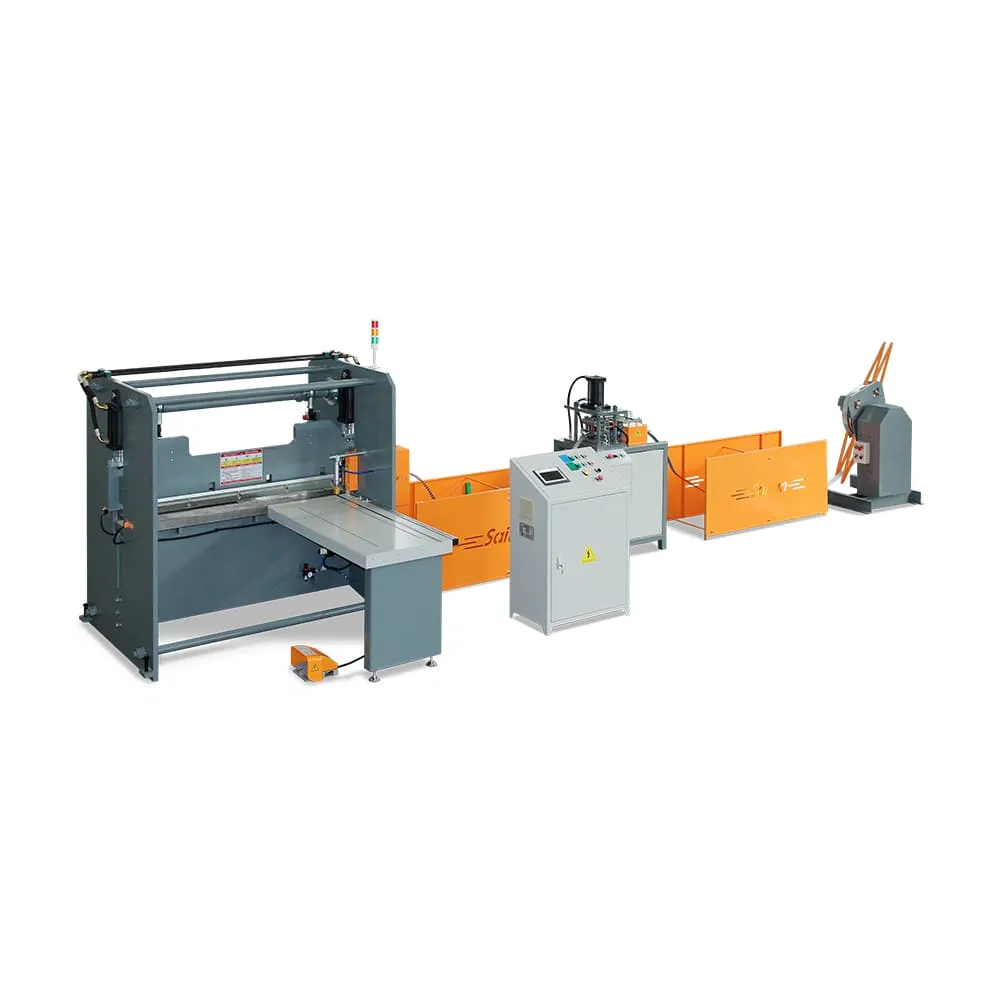

Case Study: SHANDONG HICAS MACHINERY GROUP CO LTD’s Innovation in Nailless Assembly

One major player in the industry has completely changed how hardware-free packaging works by combining CNC milled joints with steel reinforced corners on their nailless plywood box machines. The new design gets rid of all those metal fasteners but still holds up under 1800 pounds of weight, which solves a lot of durability issues that come up during tough shipping conditions. What's really impressive is that putting these boxes together takes about 40 percent less time than regular nailed boxes. This makes sense for companies looking to scale up production while keeping things green in industrial packaging applications.

Packaging Innovations and Advancements in Automotive and Heavy Machinery Sectors

More and more companies are turning to nailless plywood box machines when shipping automotive parts these days. These boxes have tight joint tolerances around -0.2 to +0.1 mm which really helps stop parts from getting damaged by vibrations during transport. Most manufacturers mix E-1 grade birch plywood with those neat modular stacking options, so they can build custom setups for different engine components and machine parts as needed. Getting rid of those sticking out nails has actually cut down warehouse injuries quite a bit – somewhere around 27% according to the Industrial Safety Journal last year. Plus, when containers get broken down following standard procedures, we're seeing space savings of about 22% in our warehouses too.

Future Outlook: Smart Integration and Modular Nailless Systems

New AI based predictive maintenance tech is now monitoring joint stress as it happens, giving workers early warnings about wear before things actually break down. Some companies have started making mixed systems where they pair traditional mechanical locks with eco friendly glues for those really tough conditions. At the same time, machines connected to the cloud let technicians tweak cutting settings from anywhere. All these advances mean nail free methods could take around a third of the industrial wood packaging market by mid next decade. The push comes mostly from green regulations and how well these systems work with automated production lines.

FAQ Section

What are nailless plywood box machines?

Nailless plywood box machines are machinery used to create packaging boxes without the need for traditional hardware such as nails, screws, or glue. They utilize CNC-cut dovetail joints and compression-locked corners for assembly.

How do nailless boxes benefit the environment?

Nailless boxes reduce environmental impact by eliminating metal fasteners, which can contaminate recycling streams. They offer a completely wooden packaging solution and significantly lower factory emissions compared to traditional methods.

Are nailless plywood boxes as strong as nailed boxes?

Yes, nailless plywood boxes show equivalent static strength to nailed boxes. They feature interlocking joints that distribute weight evenly and demonstrate enhanced resilience to dynamic impacts and environmental factors.

How does CNC technology contribute to the precision of nailless boxes?

CNC technology ensures high precision in cutting joints with accurate tolerances, which is crucial for hardware-free assembly. It allows for adjustments based on plywood density, ensuring consistent and reliable fit and finish.

What industries are adopting nailless plywood boxes?

Industries like automotive manufacturing, heavy machinery, and other sectors focused on sustainable practices are increasingly adopting nailless plywood box technology for its economic and environmental benefits.

Table of Contents

-

How Nailless Plywood Box Machines Work: Precision Engineering and Hardware-Free Assembly

- Phenomenon: The Shift Toward Hardware-Free Packaging Assembly

- Principle: How Nailless Plywood Box Machines Eliminate the Need for Nails, Screws, and Adhesives

- Interlocking Box Design Without Hardware: Precision-Cut Joints and Mechanical Locking

- Role of CNC Precision in Ensuring Consistent Joint Fit and Finish

-

Strength, Durability, and Performance of Nailless Plywood Packaging Under Industrial Conditions

- Strength and Durability of Nail-Less Packaging Under Industrial Stress Tests

- Comparative Data: Load Capacity of Nailless vs. Nailed Plywood Boxes

- Use of E-1 Grade Plywood and Steel Corner Reinforcement for Structural Integrity

- Controversy Analysis: Can Nailless Boxes Truly Replace Traditional Fastened Designs?

- Sustainability and Environmental Benefits of Nailless Plywood Box Technology

- Manufacturing Efficiency and Cost Advantages in Nailless Packaging Production

- Industrial Applications and Future Innovations in Nailless Box Machine Technology