Understanding Automated Nailing Machines and Their Core Technology

How Automated Nailing Machines Streamline Pallet Assembly Workflows

Nailing machines that work automatically take away the need for people to position boards manually and hit them with hammers. These machines combine special servos with those PLC boxes that control everything. When these parts work together, they line up boards just right and drive nails one after another at speeds around 12 per second. That cuts down on how long it takes to build each pallet, saving about 40 to 55 percent of the time compared to doing it all by hand. For companies stuck with slow spots in their workflow, especially when putting together complex structures that need multiple pieces connected together, this kind of automation really helps move things along faster.

Key Components: Servo Motors, Touch Screen PLC Control, and Auto-Stacking Features

Three critical systems drive performance:

- Servo motors (0.02mm positioning accuracy) ensure component alignment within ±0.5mm tolerance

- Touch screen PLC interfaces enable operators to preset nail patterns for 28+ pallet configurations

- Auto-stacking mechanisms with vertical lift capacities up to 1,200kg/hour streamline post-assembly handling

Facilities using these components achieve 98.3% first-pass quality rates in pallet joint integrity tests, according to industry reports.

The Role of Precision Engineering and Automation in Consistent Nail Placement

The latest motion control tech actually adjusts on the fly when dealing with different wood densities ranging from around 350 to 750 kg per cubic meter, which helps keep those nails going in at consistent depths every time. We've got these laser sensors now that check where each nail lands in relation to the edge of the boards, getting it right within just 0.8mm. That kind of precision matters a lot because if nails are off even slightly, whole pallet racks can fail under load. The 2023 report on pallet durability showed something pretty impressive too - fully automated systems cut down structural problems by nearly two thirds compared to what we see with semi-automated setups. Makes sense really, since all that engineering detail just works better than trying to mix human oversight with machine work.

Boosting Production Efficiency with Automated Nailing Systems

Maximizing Throughput: Cycle Speed and Output Capacity in High-Volume Production

Modern automated nailing machines achieve production speeds of 80–120 cycles per minute through servo motor technology and PLC-controlled workflows. This enables facilities to produce 1,200+ standardized pallets per 8-hour shift—triple the output of manual operations. The integration of auto-stacking features further optimizes throughput by eliminating downtime between production batches.

Measurable Efficiency Gains: Average Output Increase of 60–75% Post-Automation

Wooden pallet manufacturers achieve 60–75% higher daily output after implementing fully automatic systems. This stems from three key factors:

- Continuous 24/7 operation without fatigue-related slowdowns

- 0.5mm nail placement precision reducing material waste

- Instant toolpath adjustments via touchscreen interfaces

These improvements contribute significantly to overall production scalability and consistency.

Fully Automatic vs. Semi-Automated Systems: Performance Comparison

| Metric | Fully Automatic Systems | Semi-Automated Systems |

|---|---|---|

| Output/Hour | 90–110 pallets | 45–60 pallets |

| Labor Requirements | 1 operator | 3–4 workers |

| Error Rate | <0.2% | 1.8–2.5% |

Fully automated configurations demonstrate 92% higher energy efficiency per pallet compared to manual-driven semi-automated models.

Scalability of Automatic Nailing Machines for Growing Demands

Modular designs allow manufacturers to scale production capacity by 40–200% through:

- Adjustable nail pattern presets for custom pallet specifications

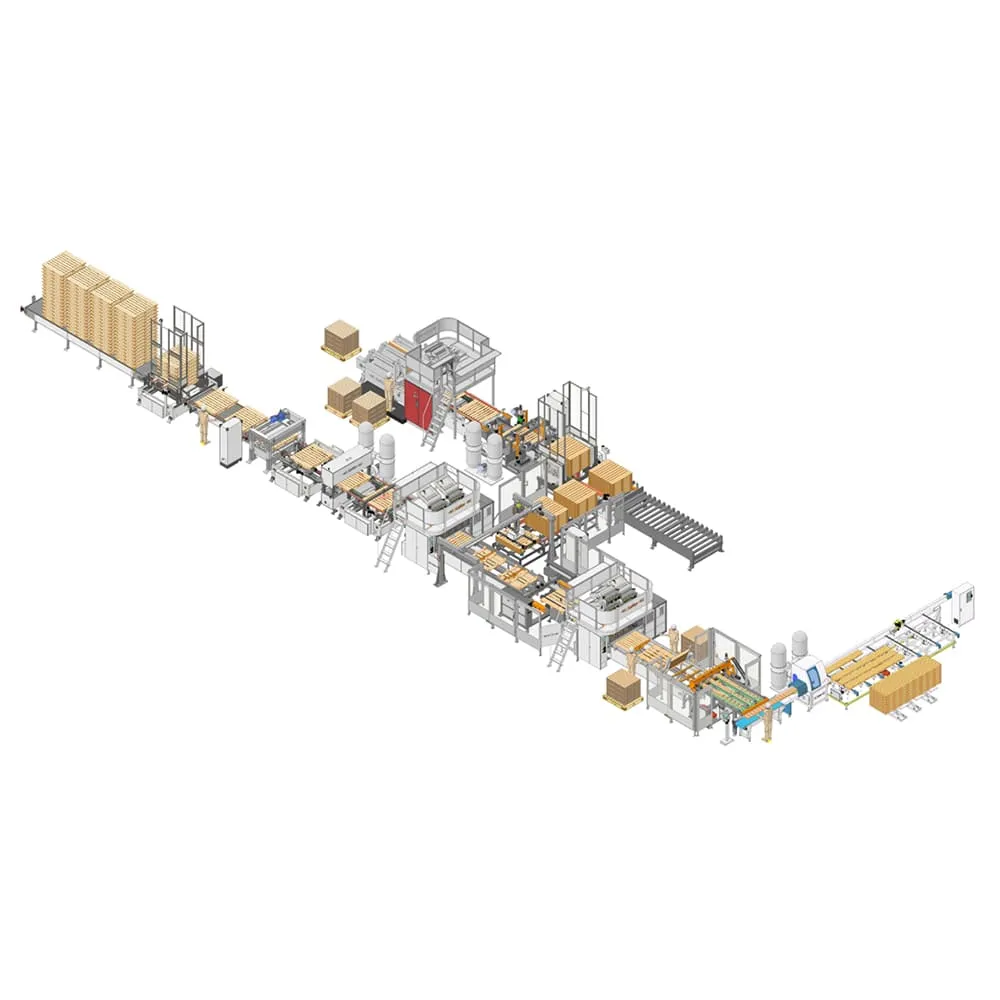

- Expandable conveyor integrations for multi-stage assembly lines

- Cloud-enabled PLC systems that synchronize machine networks

This scalability enables facilities to handle +300% order volume fluctuations without workflow overhauls.

Reducing Labor Costs and Enhancing Operational Output Through Automation

Labor cost reduction by minimizing manual involvement in pallet nailing

Nailing machines that automate the process cut down on labor costs because they take over those boring repetitive jobs that would normally need 3 or 4 people at each workstation. Plants that have adopted this technology report saving around 60 to 75 percent of their manual labor time without any drop in product quality according to CCR Magazine from last year. These machines place nails with such accuracy that mistakes which cost money just don't happen anymore. Woodworking businesses see their operating expenses go down between 30 and 50 percent when switching to automated systems. The savings come not only from fewer worker hours but also from less wasted material due to misfired shots or crooked fastenings.

Case study: Labor efficiency improvements at a leading industrial machinery manufacturer

One major manufacturer based in East Asia managed to cut down their pallet assembly labor expenses by around 40% just six months after bringing in automated nailing technology. They installed these servo controlled machines right into their current production lines and moved 15 of their experienced workers over to handle quality checks and fine tuning processes across different departments. What makes this case interesting isn't just the money saved on wages though. The shift shows how smart investments in automation create multiple advantages that keep growing over time. Looking at industry data from similar companies, most see returns on their automation spending anywhere between double and triple what they invested initially, usually within about three years of implementation.

Seamless Integration into Existing Lines and the Path to Smart Manufacturing

Integrating Automated Nailing Machines into Current Pallet Production Workflows

Factories today can install automated nailing machines right into their current setup without tearing everything apart, which means they don't have to throw away money already spent on conveyors and other material handling gear. The new nailing tech actually hooks up pretty well with older machinery thanks to standard connection points. Workers still follow the same basic routines they've always used, but now those boring repeat nailing jobs get handled automatically. When these systems talk to the cutting area ahead of time and coordinate with the stackers afterward, production just keeps moving at an even pace without hiccups. Most shops find this integration works surprisingly smoothly once it's all set up properly.

Matching Automation Levels to Facility Size and Production Goals

Small businesses typically go with semi automated setups where workers still place boards manually, whereas big volume factories have moved to completely automatic feeding systems and stackers. The modular approach gives companies room to grow their capabilities step by step. They can start simple then later add things like robotic arms or those fancy AI scanners when business picks up. This kind of gradual expansion stops companies from spending too much on automation upfront. Instead, they match their equipment investments to what actual production demands look like month to month.

PLC-Driven Automation as a Foundation for Smart, Connected Pallet Factories

PLC systems turn those automated nailing machines into real data hubs inside smart manufacturing setups. The sensors built right in monitor things like how long each cycle takes, where nails actually land compared to where they should go, and when parts need replacing. All this information gets sent to central dashboards so operators can see what's happening in real time. Some studies looking at these integrated platforms found that connected systems let factories predict when equipment might fail, cutting down unplanned stoppages by around 20% in woodworking shops. As companies keep improving their PLC compatibility, it opens doors for bigger IoT projects across entire operations. This connection between shop floor data and warehouse systems means manufacturers can finally get all their information talking to each other instead of sitting in silos.

FAQ

What are automated nailing machines?

Automated nailing machines are equipment that automate the process of aligning boards and driving nails, reducing the need for manual labor. They are designed to efficiently assemble items like wooden pallets by using technology such as servo motors and PLC systems.

How do automated nailing machines improve production efficiency?

These machines streamline workflows by significantly increasing the speed of assembly, achieving up to 12 nails per second, and reducing manual labor, which saves time and increases output compared to hand-nailing methods.

What components make up these automated systems?

Key components of automated nailing systems include servo motors for precise alignment, touch screen PLC controls for programmable functions, and auto-stacking mechanisms for efficient post-assembly handling.

Can automated nailing machines be integrated into existing production lines?

Yes, automated nailing machines can be seamlessly integrated into existing setups with minimal alterations, aligning with current workflows and machinery through standard connections.

What are the labor cost benefits of automated nailing machines?

By reducing manual involvement, automated nailing systems lower labor costs by decreasing the number of required workers and minimizing mistakes related to manual errors, thus saving on operational expenses.