Evaluate Build Quality and Performance of Wood Working Machine Manufacturer Products

Understanding testing and evaluation criteria for machines

Industrial buyers should prioritize manufacturers that follow ISO 9001-certified testing protocols. Key performance indicators include torque consistency (±3% variance), cutting precision (<0.1mm tolerance), and vibration control (<2.5 m/s²). According to a 2023 production efficiency study, machines meeting these standards reduced material waste by 18% compared to non-certified models.

Assessing build quality of power tools and components

Durability begins with material selection—aircraft-grade aluminum frames and hardened steel gears that show ≤0.05% wear after 500-hour stress tests are ideal. Research from materials science experts confirms that tungsten-carbide blade coatings improve impact resistance by 40% in hardwood milling applications.

Analyzing durability and longevity in real-world applications

Field data from 142 cabinet shops highlights significant differences between premium and economy models:

| Metric | Premium Machines | Economy Models |

|---|---|---|

| Mean Time Between Failures | 2,100 hours | 680 hours |

| Part Replacement Cost/Year | $320 | $1,450 |

Machines maintaining ≥85% performance after five years typically feature dual-bearing motors and thermal overload protection, contributing to longer service life and lower operating costs.

Comparing performance metrics across leading wood working machine manufacturer brands

When comparing brands, evaluate these operational benchmarks:

- Cutting Speed: 25–35 m/min for precision joinery tools

- Dust Extraction: ≥98% efficiency in capturing 5-micron particles

- Power Consistency: ≤5% voltage drop under maximum load

Units exceeding these thresholds demonstrated 31% faster production times in peer-reviewed woodshop trials, underscoring the impact of high-performance engineering on workflow efficiency.

Assess Brand Reputation and Customer Trust in Wood Working Machine Manufacturer Selection

Role of brand reputation in purchasing decisions

Brand reputation reflects decades of consistent performance and reliability. Over 85% of professional woodworkers prefer established manufacturers, viewing them as indicators of rigorous quality control and engineering excellence. In industrial settings where downtime is costly, trusted brands reduce risk and support confident investment decisions.

Customer reviews and third-party ratings for reliability assessment

Looking at third party reviews gives people an idea of how these machines actually perform when put through their paces in everyday situations. Many folks have noticed problems with things like motors that don't deliver consistent power or blades that start wearing down way too soon after purchase. Industry experts often check several different review sites side by side to spot any common complaints that keep coming up again and again across different customer experiences. A machine that maintains around 90 percent good ratings for at least five years on the market tends to last much longer than average models. Getting ISO 9001:2015 certified isn't just some paperwork exercise either it shows manufacturers follow strict quality control procedures throughout production, which ultimately translates to fewer defects and better overall product reliability for end users.

Country of origin and manufacturing quality perceptions

Certain regions are historically associated with precision engineering and strict regulatory oversight, often correlating with a 30% longer service life in machinery. However, leading manufacturers globally now adhere to international quality standards, making factory audits a more reliable measure of build integrity than country of origin alone.

Examine Product Range and Innovation Across Wood Working Machine Manufacturer Offerings

Matching product lines to use cases: hobby, home business, and commercial

When it comes to manufacturing equipment, companies design their product ranges around what different users actually need. Hobby woodworkers typically go for smaller benchtop options, stuff like those 10 inch table saws and portable planers that fit nicely on a garage workbench. For people running home workshops as side businesses, there's a whole category of mid range combo machines out there. These jointer planer hybrids can handle roughly 500 board feet weekly without breaking a sweat. Then we get to commercial shops where things get serious fast. They're talking about big ticket items like industrial CNC routers and heavy duty hydraulic presses meant to run non stop day after day. These machines come with all sorts of built in features too dust collection systems and reinforced frames that stand up to constant pounding.

Integration across tool ecosystems and compatibility

The best tool makers are now building products that work together digitally without much fuss. Think smart docking stations, remote controls that connect wirelessly, and software that keeps everything in sync whether it's a router, sander or saw. No more recalibrating each machine separately when they all talk to each other. Manufacturers also include standard dust ports and rail mounts so accessories can be shared between different machines. Getting the control software to play nice with older gear is another big deal since disconnected workflows waste time and money. Research indicates these isolated systems can actually cut down productivity anywhere from 15 to 22 percent over time.

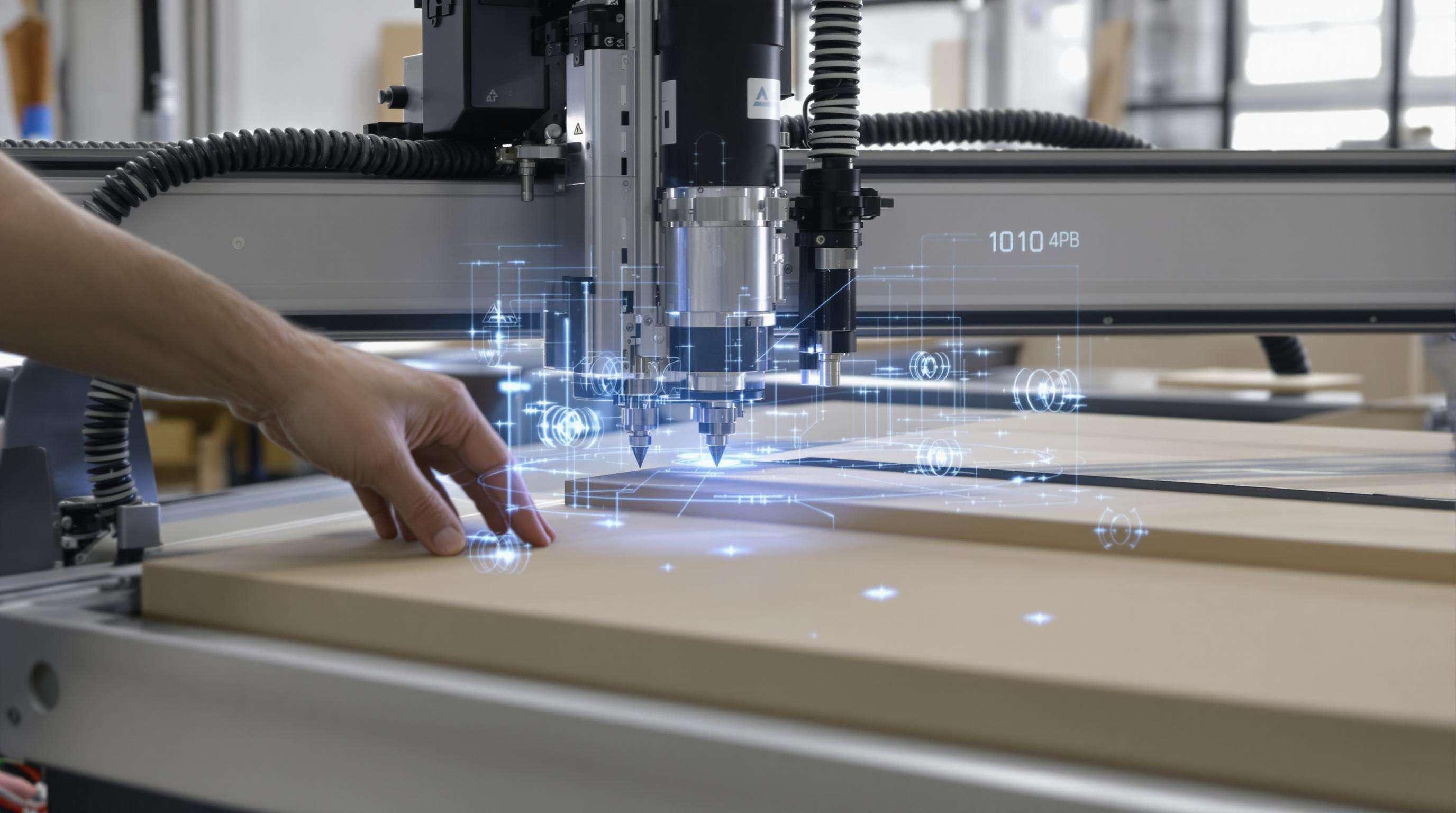

Innovation in usability, safety, and digital features

The latest tech advancements are all about making things safer, more accurate, and easier to handle. With augmented reality now being used in workshops, workers can see exactly where cuts need to be made right on the material itself, which cuts down those pesky layout mistakes we all hate. There's also this amazing contactless braking system that actually stops blades super fast—in just half a second when it detects skin contact. Pretty impressive safety feature if you ask me. Manufacturers are installing IoT sensors everywhere these days to keep an eye on vibrations and blade tension. These little gadgets help predict when something might fail, cutting down equipment failures by around 40%. Another cool development is digital twin technology. Before making any actual cuts, these virtual models let operators test out their plans first, so everything turns out much more accurate than before. According to industry reports, shops using these connected systems report about 32% fewer processing errors compared to older methods that didn't have all this smart connectivity built in.

Analyze Price, Warranty, and Long-Term Value from a Wood Working Machine Manufacturer

Balancing upfront cost with long-term ROI and operational efficiency

Looking only at what something costs when bought misses out on all those hidden expenses down the road. Machines that aren't efficient tend to eat through energy bills and materials faster than they should. Sure, premium equipment comes with a bigger price tag upfront, but these often end up costing about 30 percent less over their whole lifespan. Think about everything involved in owning machinery: how much power it guzzles, how often parts need replacing, production speed, and time lost when things break down. The Department of Energy reported in 2023 that switching to high efficiency motors saves around nine hundred fifty dollars each year just on electric bills alone. Better dust collection systems also mean filters last longer before needing replacement, which cuts down on both hassle and repair costs over time.

| Cost Factor | Short-Term Impact | Long-Term Impact |

|---|---|---|

| Energy Consumption | Immediate utility bills | 5-7 year operational costs |

| Maintenance Frequency | Service intervals | Cumulative downtime hours |

| Production Yield Rates | Daily output | Annual material savings |

Evaluating warranty coverage, length, and claim ease

When manufacturers stand behind their products with solid warranties, it usually means they believe in what they're selling. For serious equipment purchases, aim for minimum three year coverage on those essential parts such as spindles and controllers, covering not just replacement parts but also the actual labor costs when technicians need to come onsite. Maintenance logs matter a lot too many folks don't realize that roughly 4 out of 10 warranty claims get rejected simply because proper maintenance wasn't documented according to Industrial Equipment Journal from last year. Before finalizing any purchase, check if travel expenses will be absorbed by the warranty and whether common wear-and-tear components like bearings or drive belts are actually included. Some top manufacturers have started implementing QR code systems for processing claims these days, which cuts down on how long it takes to resolve issues by almost two thirds compared to traditional methods.

Hidden costs: Maintenance, parts availability, and downtime risks

When equipment breaks down unexpectedly, companies often lose thousands each day just sitting idle waiting for repairs. We've seen instances where one broken gear alone can set back operations by around $12k in lost production time. Make sure to check if the manufacturer keeps spare parts readily available within the country. If they don't have warehouse locations across the US, expect waits of about two weeks before replacements arrive. There are other hidden expenses too like expedited shipping charges at roughly $280 per component needed, plus paying outside tech experts at about $160 an hour when internal staff can't fix things fast enough. While shopping around for new equipment, it's worth pushing for those regular maintenance packages and asking specifically about their Mean Time Between Failures stats. A few forward-thinking suppliers even throw in lifetime access to online support centers complete with handy diagnostic software at no extra charge.

Prioritize After-Sales Support and Manufacturer Ecosystem for Sustainable Operations

Training, Documentation, and Software Integration Support

According to Machinery Safety Quarterly from 2023, around 60% of all downtime related to equipment happens because people just don't know how to use things properly. That's why good training really matters. Top companies in the industry aren't just handing out manuals anymore. They actually invest time in proper onboarding processes. Some offer video guides showing step by step how to maintain different machines. Others bring engineers into factories for hands-on sessions where workers learn to program complicated setups like those pneumatic clamps everyone struggles with. And let's not forget about documentation either. The best manufacturers now provide multiple formats so people can access information however works best for them. Plus there's usually some kind of software support built right into these systems, which makes getting comfortable with newer tech like CNC routers or automated planers much less intimidating than it used to be.

Service Network Responsiveness and Field Technician Access

Having a round-the-clock hotline means nothing if there's no tech support within driving distance. The best equipment vendors have local service centers across different regions, usually guaranteeing under ninety minutes response time when things go south with major issues such as broken spindles or clogged dust collection systems. For folks shopping from remote locations, checking whether these service points actually cover their area makes all the difference. Nobody wants to wait days for repairs on expensive machinery like big belt sanders or heavy duty jointers that need specific diagnostic gear and specialty tools for fixes.

Case Study: How Reliable Manufacturers Enable Small Workshop Growth

The little woodworking shop in Vermont saw their monthly production jump nearly triple when they partnered with a manufacturer that had these smart edge banding machines. The system sends warnings before things break down, cutting unexpected stoppages by around 41 hours each month. And no more waiting weeks for replacement parts either since the new setup delivers what's needed right when it's needed. What this shows is pretty straightforward really: when manufacturers build better support systems around their equipment, what was once just another expense becomes something that actually helps grow the business over time.

FAQ Section

What should I consider when evaluating woodworking machines?

Key factors include torque consistency, cutting precision, vibration control, and compliance with ISO 9001-certified testing protocols.

How does brand reputation impact my purchasing decision?

Brand reputation often reflects consistent performance and reliability. Established brands are preferred for their rigorous quality control.

What are the hidden costs of owning woodworking machines?

Hidden costs can include maintenance, parts availability, and downtime risks. It's important to factor in these aspects when purchasing equipment.

Why is after-sales support important for woodworking equipment?

Good after-sales support ensures proper training, documentation, and quick repair services, minimizing downtime and maximizing productivity.

Table of Contents

- Evaluate Build Quality and Performance of Wood Working Machine Manufacturer Products

- Assess Brand Reputation and Customer Trust in Wood Working Machine Manufacturer Selection

- Examine Product Range and Innovation Across Wood Working Machine Manufacturer Offerings

- Analyze Price, Warranty, and Long-Term Value from a Wood Working Machine Manufacturer

- Prioritize After-Sales Support and Manufacturer Ecosystem for Sustainable Operations

- FAQ Section