The Evolution and Impact of Fully Automatic Pallet Production Systems

Fully automatic pallet production systems have revolutionized wood processing, with the global market for pallet making machine for sale expanding by 24% annually since 2020 (Ponemon 2023). These systems address three critical challenges: labor-intensive workflows, material waste, and inconsistent output quality.

How automation in pallet manufacturing is transforming the industry

Modern machines now complete a pallet in 90 seconds—6 faster than manual methods—while reducing wood waste by 18% through AI-optimized cutting patterns. This shift enables manufacturers to meet big-box retailer demands for 48-hour turnaround on custom pallet orders.

Key drivers behind the adoption of automated production processes

Three factors dominate automation decisions:

- Labor costs: Automated systems reduce workforce requirements by 73% per production line

- Precision: Vision-guided nailing achieves 0.2mm alignment tolerance vs 3mm manual variance

- Scalability: Modular designs let manufacturers add capacity in 25-pallet/hour increments

Data insight: 68% increase in demand for industrial automation in wood processing (2020–2023)

The COVID-era supply chain crisis accelerated adoption, with 82% of mid-sized manufacturers now prioritizing automation investments. Early adopters report 14-month ROI timelines through combined gains in output (+220%), defect reduction (-91%), and energy efficiency (+34% kWh/pallet).

Core Technologies in Pallet Making Machine for Sale

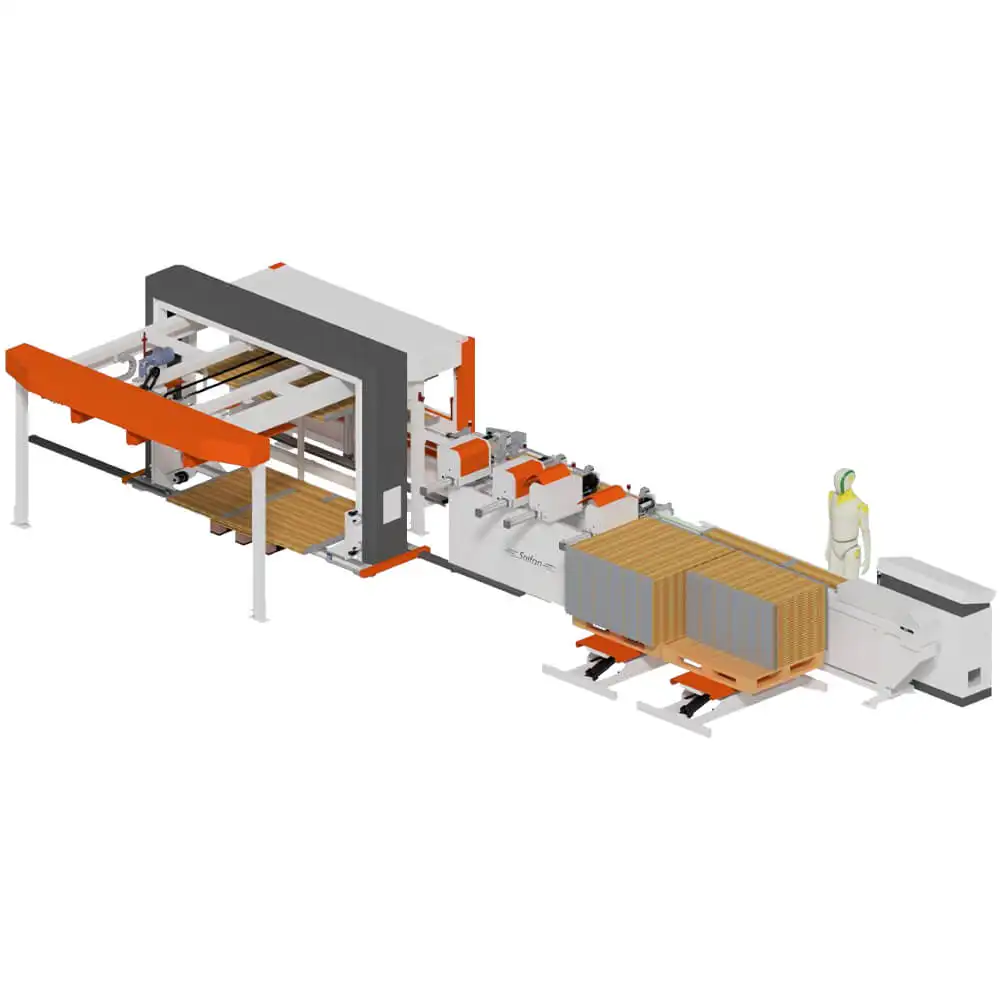

Integration of manufacturing robotics in scalable pallet production solutions

The latest pallet making machines on the market are starting to incorporate what's called collaborative robots or cobots that team up with CNC routers and nailing equipment. These little helpers take care of all the boring repetitive stuff like placing boards just right and applying those fasteners with pretty impressive precision around 0.1 mm give or take. This setup lets factories run nonstop day after day. Shops that have made the switch to these robot partners report seeing their productivity jump nearly double compared to when workers did everything by hand, plus they save about a third on labor expenses. And here's another bonus for manufacturers looking to scale up: most systems come with modular designs so companies can simply plug in additional robotic arms whenever business picks up without having to completely redesign their whole operation from scratch.

Vision-based cutting technology for pallets: Precision meets efficiency

Camera-guided cutting systems now achieve 99.5% material utilization in pallet making machines for sale. Laser scanners map wood grain patterns to optimize cuts, minimizing waste while maintaining ISO 6780 load-bearing standards. This technology reduces raw material costs by 12–18% compared to manual sawing, according to 2024 timber efficiency benchmarks.

Role of material handling automation in minimizing downtime

Automated conveyors and pallet stacking systems eliminate manual transfers between workstations—historically responsible for 23% of production delays. One Midwest manufacturer reduced machine idle time by 41% after implementing automated material handling, processing 880 pallets per shift instead of 620.

High initial cost vs. long-term ROI: Evaluating the financial case for automation

| Metric | Manual Production | Automated System |

|---|---|---|

| Labor Cost/Hour | $38 | $9 |

| Error Rate | 8.2% | 0.9% |

| Max Output (Pallets/Day) | 1,200 | 3,400 |

While automated pallet making machines for sale require $250k–$800k upfront investments, most operations break even within 18–24 months. A European case study showed full automation reduced total labor costs by 81% while doubling production quality scores.

Performance Comparison: Manual vs. Fully Automatic Pallet Production

Manual vs. Automated Production Processes: Output, Accuracy, and Labor Costs

When workers build pallets by hand, they typically manage around 40 units each hour, but quality can vary quite a bit because mistakes happen. Automated systems completely change this picture, cranking out between 120 to 220 pallets per hour thanks to PLCs and robots doing the heavy lifting. Manual operations need anywhere from four to six people working during a single shift, whereas automation cuts down on staffing requirements by roughly 70 percent according to Material Handling Institute data from last year. Another big plus for automation is how it slashes material waste. Studies show automated processes cut waste levels by about 12 to 18 percent over traditional methods since smart software actually calculates optimal ways to use every piece of lumber efficiently throughout production runs.

| Metric | Manual Production | Fully Automated | Improvement (%) |

|---|---|---|---|

| Output/Hour | 40 | 220 | 450% |

| Labor Cost/Pallet | $3.80 | $0.90 | 76% Reduction |

| Defect Rate | 5.2% | 0.7% | 87% Improvement |

Case Study: German Manufacturer Increases Output by 220% with Full Automation

One pallet maker based in Central Europe made the switch to completely automated nailing and stacking equipment last year, and saw their output jump by around 220% over just six months. They spent about $1.2 million on those fancy robotic arms guided by computer vision technology, which started paying for itself after roughly 14 months. The biggest wins? Overtime expenses dropped nearly two thirds, and they had far fewer customer complaints about pallets that didn't fit properly because of size issues. Looking at industry reports from around the world, most companies see their money back on similar automation projects between 18 and 22 months later even though the initial price tag is definitely steep. Still, the long term benefits seem worth it for many manufacturers trying to stay competitive.

Global Trend Toward Materials Handling Automation in Logistics and Manufacturing Hubs

The demand for automation in wood processing industries jumped about 68% from 2020 to 2023 according to the Ponemon Institute report last year, mainly because companies are struggling to find enough workers and online shopping keeps growing fast. Most of these automated pallet machines get bought in Asia Pacific regions, which makes up around 41% of all purchases there. People in this area really like modular systems since they can expand alongside warehouses when business grows. Looking at the latest data from the Logistics Automation Report 2024 shows similar trends too. Nearly 8 out of 10 manufacturers said having consistent output rates was what made them invest in those pallet making machines available on the market today.

Customization and Flexibility in Modern Pallet Making Machines

How modern pallet making machines support variable pallet specifications

Modern automated systems can manage all sorts of different pallet sizes thanks to their programmable features and adaptable hardware. Warehouse staff typically toggle between standard sizes like the familiar 48x40 inch pallets and custom options such as European pallet formats or special arrangements needed for drinks distribution, all controlled via intuitive touchscreens that take just a few minutes to set up. No more wasting time with manual adjustments means factories can run multiple product types back to back without slowing things down. Smart control systems automatically tweak nail placement and spacing between boards according to digital plans, keeping everything within tight tolerances around half a millimeter. These flexible manufacturing options cut down on wasted materials by roughly a quarter, which makes sense when companies need to produce small batches quickly to meet unusual shipping requirements or last minute orders.

Flexible tooling systems for diverse material types and sizes

The machine comes with interchangeable tool heads that work just fine on all sorts of materials including softwoods, hardwoods, plastic composites, even recycled stuff without needing to stop production for retooling. The modular jigs are pretty smart too. When the sensors pick up changes in material thickness, they automatically adjust the guides and clamps. Works smoothly across thicknesses ranging anywhere from 15mm right up to 50mm. Swapping out cutting assemblies takes less than eight minutes thanks to those quick release mechanisms, so we can switch back and forth between regular timber and heat treated wood without missing a beat. This kind of flexibility really helps deal with unpredictable supply chains because it opens up about 40-45% more options for raw materials. Looking ahead, newer models will feature RFID tagged tools that connect with industrial internet of things systems. These connections let the equipment make predictions and adjustments as new sustainable materials come onto the market, like that compressed agricultural waste everyone's talking about lately.

Scalable and Future-Ready Pallet Production Solutions

Modular automation for growing warehousing and logistics operations

Modular pallet makers adjust well to changing production needs without requiring total system replacements when expanding operations. Companies simply add more robotic assembly parts or extend conveyors as their output demands increase. Logistics automation research from last year shows these systems keep downtime below 1% even during major expansions. The ability to scale this way cuts down on money tied up in equipment by around 40% versus traditional fixed setups, all while keeping product quality consistent across different locations. Being able to work with over 30 types of pallets lets warehouses switch back and forth between European standards, display models, and regular industrial pallets. This kind of flexibility matters a lot for distribution centers that serve several retailers at once.

Future-proofing investments with expandable fully automatic pallet production systems

Putting money into expandable pallet production machines makes sense for companies wanting to stay ahead of changing market demands without hurting their bottom line. These machines come with standard mounting spots and control systems that work with outside hardware, so factories can easily add new tech down the road. Think about those fancy sensors that predict when parts might fail or quality check systems powered by artificial intelligence. Once these machines are up and running, there's no need to wait until everything is installed upfront. When manufacturers skip out on proprietary restrictions, they actually keep around 22 percent more value in their equipment after it's used for years. Plus, these systems tend to run efficiently for about 15 years according to what leading equipment makers have found through their testing over time.

FAQ

What are the main benefits of fully automatic pallet production systems?

Fully automatic pallet production systems provide significant advantages in labor cost reduction, precision, scalability, and material waste reduction. They also ensure faster turnaround times and increased output efficiency.

How do automated systems improve pallet production accuracy?

Automated systems utilize vision-guided nailing and AI-driven processes to maintain high alignment tolerance and ensure precise cuts, dramatically reducing error rates compared to manual production methods.

What financial aspects should be considered when investing in automated pallet machines?

Investments in automated pallet machines may require substantial upfront costs, but these are often recouped within a short term due to reduced labor costs, increased output, and improved product quality.

What role does scalability play in pallet production automation?

Scalability allows manufacturers to adjust production capacity easily without major system overhauls, making it easier to handle fluctuating demand and expand operations as needed.

How does automation impact the defect rate in pallet production?

Automation significantly reduces the defect rate due to consistent and precise operations, resulting in high-quality product outputs that are largely error-free.

Table of Contents

- The Evolution and Impact of Fully Automatic Pallet Production Systems

- Core Technologies in Pallet Making Machine for Sale

- Performance Comparison: Manual vs. Fully Automatic Pallet Production

- Customization and Flexibility in Modern Pallet Making Machines

- Scalable and Future-Ready Pallet Production Solutions

-

FAQ

- What are the main benefits of fully automatic pallet production systems?

- How do automated systems improve pallet production accuracy?

- What financial aspects should be considered when investing in automated pallet machines?

- What role does scalability play in pallet production automation?

- How does automation impact the defect rate in pallet production?