1. Pre-milling

Two wear-resistant diamond tools are used to effectively remove the wavy patterns produced by precision panel saw cutting, ensuring the flat edge of the board for easy edge sealing.

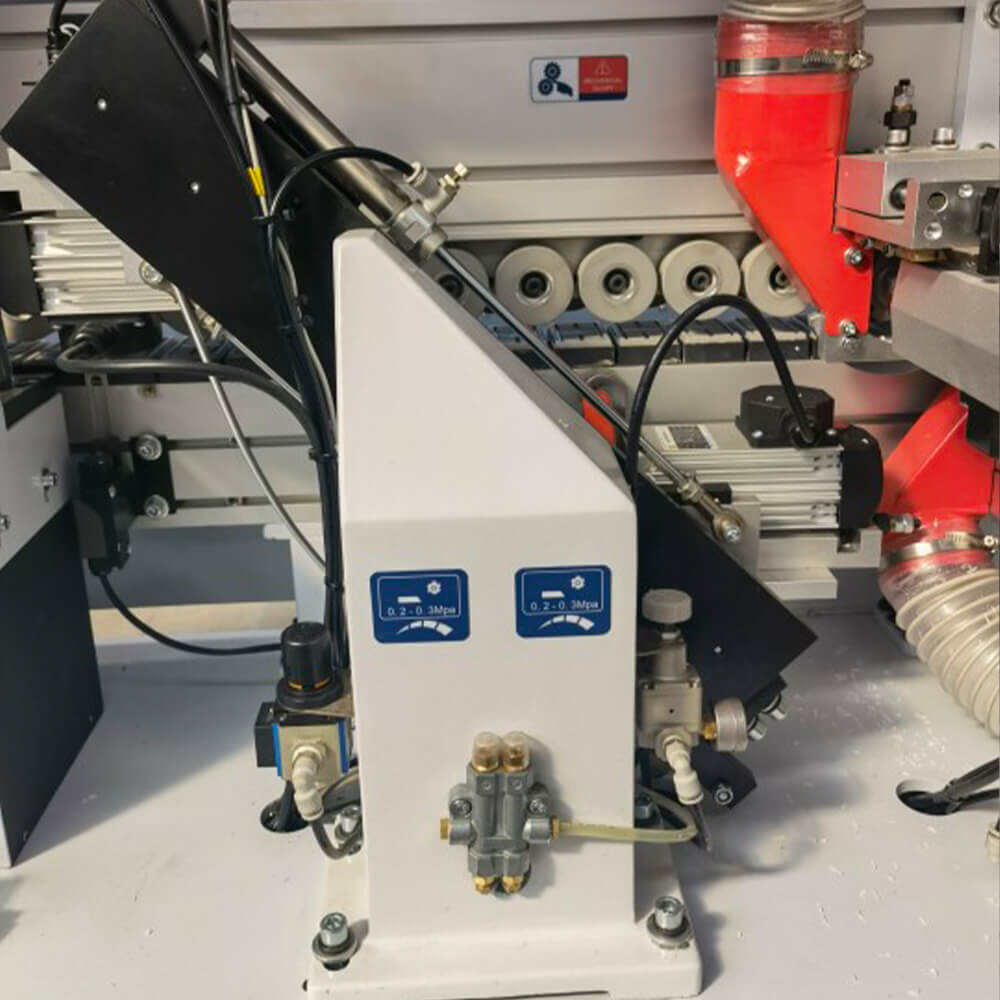

2. Gluing

Hot melt glue is added through the glue tank, and a spiral glue supply structure is used to evenly coat the board and sealing material.

3. End cutting

HX290 edge banding machine adopts a standard high-matching technical structure, and ensures a smooth cutting surface through precise linear guide motion, automatic mold tracking and high-frequency and high-speed motor fast cutting structure.

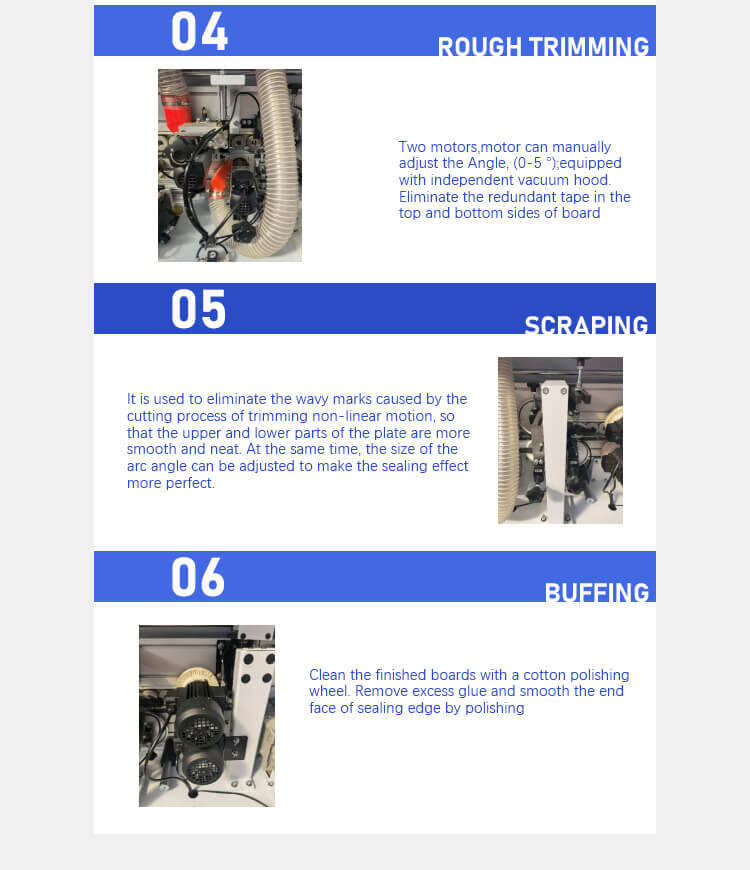

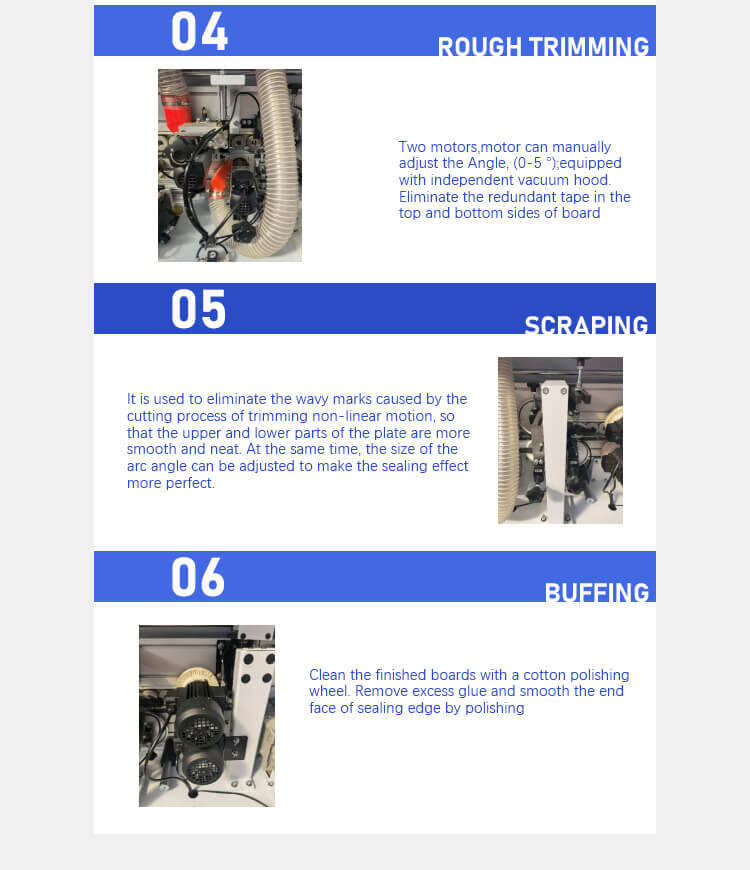

4. Rough trimming

Dual motors, the motor can manually adjust the angle (0-5°), equipped with an independent dust cover, effectively remove the excess tape on the upper and lower sides of the board.

5. Scraping glue

It is used to eliminate the wavy patterns produced during the cutting process of trimming nonlinear motion, making the board smoother and smoother from top to bottom. At the same time, the arc angle can be adjusted to make the edge sealing effect more perfect.

6. Polishing

Clean the completed board with a cotton polishing wheel. Remove excess glue and polish the edge sealing end surface to make it smooth.