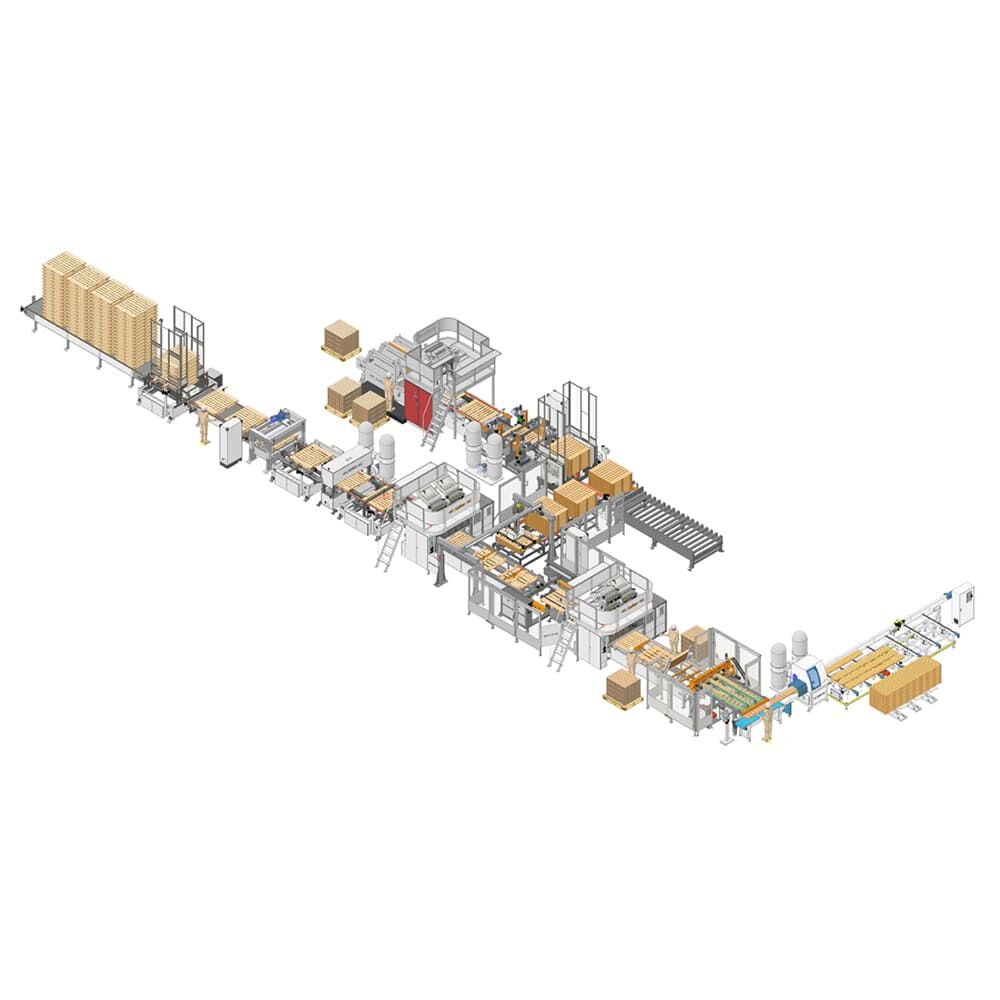

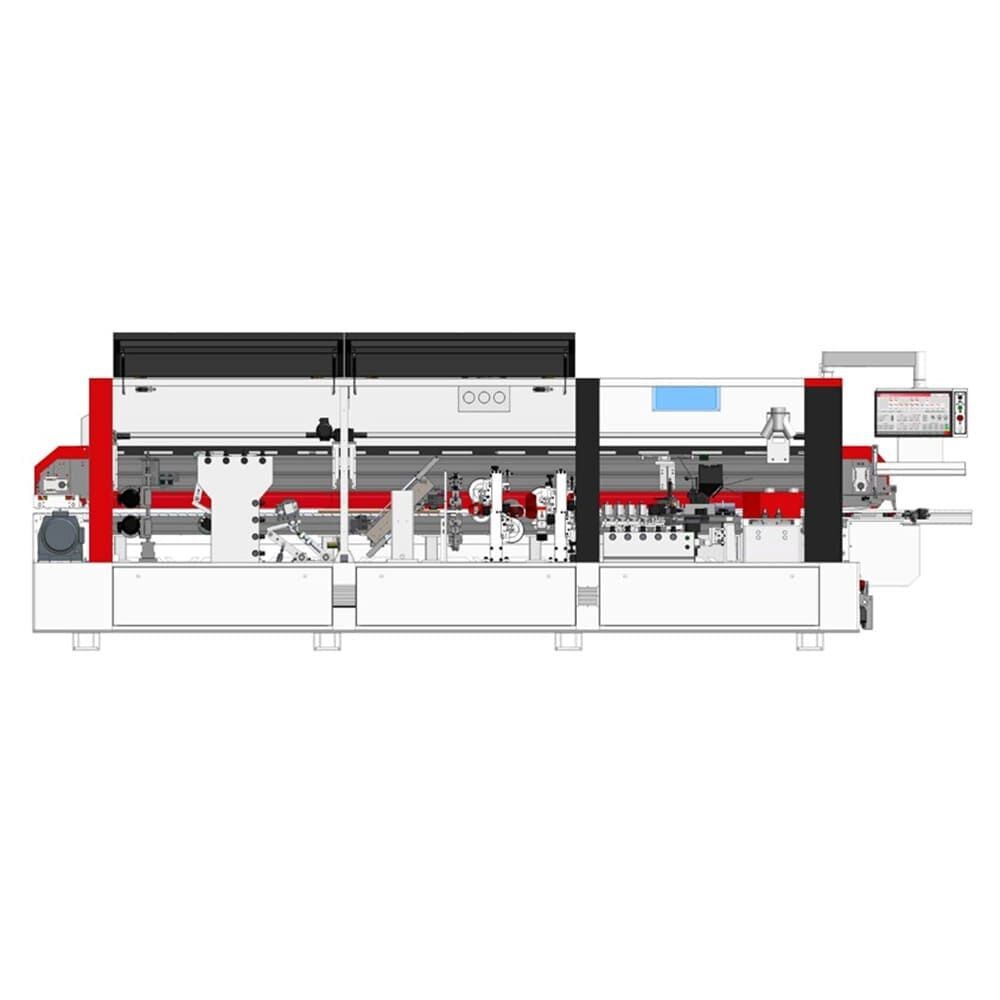

HICAS предлагает высококачественные, индивидуальные решения для производства деревянных паллет с опытом работы более 25 лет по всему миру. Наши разработки, сертифицированные ISO9001, UL и CE, обеспечивают точность, эффективность и беспрецедентное качество обслуживания во всем мире.

Контактная информация

-

Электронная почта

[email protected] -

Телефон

8618562586815 -

Адрес

Фабрика в Чэнъян: промышленная зона аэропорта, улица Хуэйда, улица Шуанъюань, район Чэнъян, город Циндао, провинция Шаньдонг, Китай.