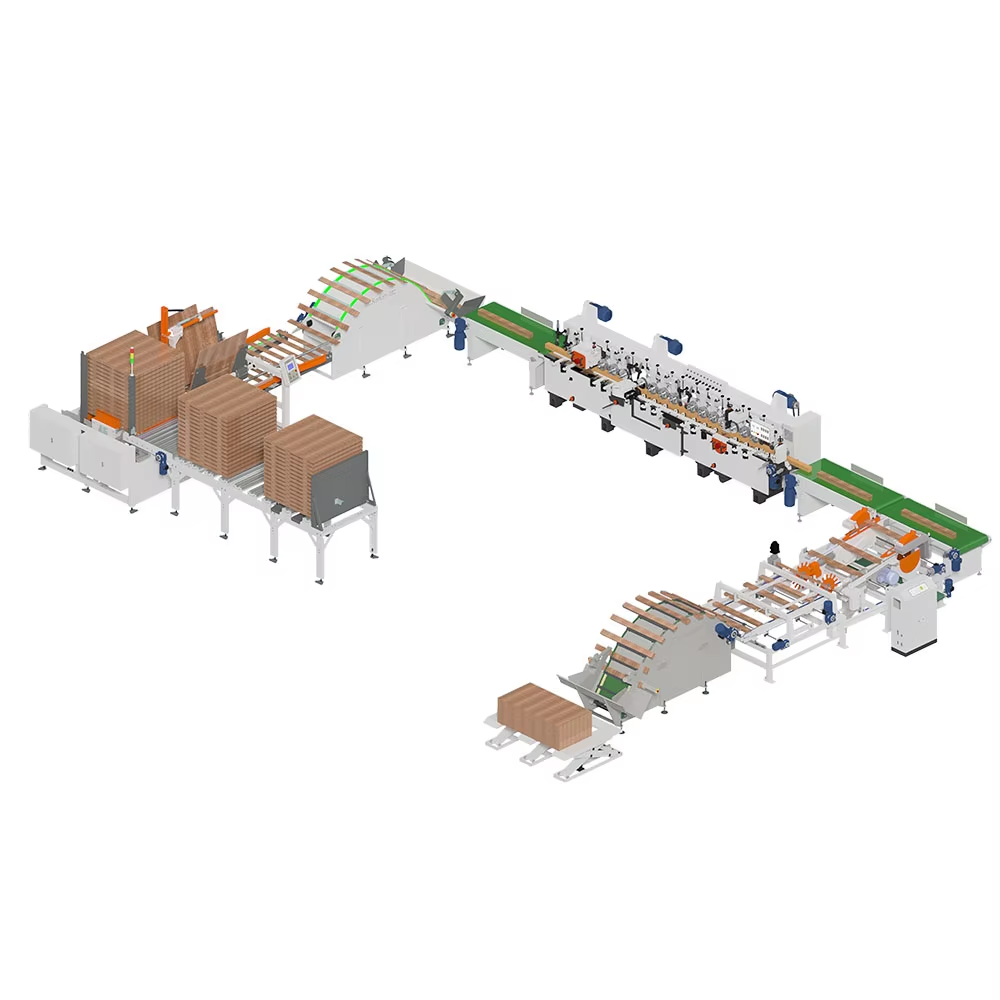

Boosted Production Speed and Dimensional Consistency

300% Uptime Increase vs. Manual Assembly Lines

Automated wooden pallet making machines deliver 300% higher operational uptime than manual assembly lines—eliminating bottlenecks in material handling and enabling facilities to process pallets three times faster. Real-time monitoring systems reduce unplanned downtime by 60%, ensuring continuous operation that meets urgent shipping windows without overtime labor.

CNC-Controlled Precision Within ±0.5mm Tolerance

CNC technology keeps pallet dimensions consistent throughout manufacturing, staying within plus or minus half a millimeter. The accuracy makes a real difference during shipping since it cuts down on product damage by almost half when loads are properly balanced. Laser guided systems also handle the tricky part about different wood densities, so deckboards stay evenly spaced despite natural variations in the material. With these improvements, we see around 30% less waste from defective pallets, which obviously saves money on materials. Plus, having standard sizes means automated guided vehicles can load and unload pallets faster, gaining about 22 seconds per unit in the process. These small gains add up significantly over time for warehouse operations.

Seamless Integration with Warehouse Automation Systems

Automated wooden pallet making machines serve as the operational backbone of modern warehouses, natively syncing with core automation technologies to eliminate manual handoffs between production and logistics—cutting fulfillment cycle times at the source.

Real-Time Sync with WMS and AMR Fleets

These systems communicate with Warehouse Management Systems (WMS) and Autonomous Mobile Robots (AMRs) at millisecond intervals, enabling dynamic rerouting of pallets based on live inventory shifts, fully automated AMR task allocation, and predictive maintenance alerts that reduce downtime by 19% (Logistics Tech Review 2023).

Measurable Cost Optimization and ROI Acceleration

Integrating an automated wooden pallet making machine transforms warehouse economics—delivering quantifiable cost reductions and accelerating financial return.

Labor Savings, Material Waste Reduction, and Payback in <14 Months

When it comes to pallet assembly, automation can slash the number of staff needed by around 70 percent, which obviously brings down payroll costs quite a bit. The precision of CNC cutting technology also makes a big difference, reducing wood waste compared to old school methods by somewhere between 25 and 30 percent. That means companies get better value from their raw materials. Throw in reduced downtime and fewer mistakes during production, and most businesses see their investment pay off within just over a year. Plants that hit this mark typically find their overall production costs drop anywhere from 20 to 40 percent. These real world savings speak volumes about how investing in automated systems isn't just good for the bottom line but also helps operations scale up without breaking the bank.

Enhanced Safety, Sustainability, and Scalability

When companies switch from manual to automated pallet assembly, they're basically taking workers out of dangerous situations involving power tools and lifting heavy loads. Safety gets better right away since people aren't handling those risky operations anymore. From an environmental standpoint, there's another big plus. The computer programs used in these systems cut down on wasted materials significantly. Some reports suggest around 22% less wood goes to waste when using automated cutting versus what happens during traditional methods. Plus, these machines don't rely on human operators for speed control. That means production can ramp up or down depending on what the market needs at any given time. Businesses can handle busy seasons without breaking a sweat and still grow steadily over years. All this helps meet those corporate sustainability goals too, which has become pretty important for many manufacturers these days.

FAQ Section

What is the operational uptime increase with automated pallet making?

Automated wooden pallet making machines provide a 300% higher operational uptime than manual assembly lines, reducing bottlenecks and enabling faster processing.

How accurate is the CNC technology in pallet manufacturing?

CNC technology maintains pallet dimensions within ±0.5mm tolerance, significantly reducing product damage and material waste.

How does the integration with warehouse systems work?

These machines seamlessly sync with Warehouse Management Systems and Autonomous Mobile Robots, optimizing logistics and reducing downtime.

What are the cost savings associated with automated pallet making?

Labor costs can drop by 70%, material waste is reduced by 25-30%, and most businesses see a payback on their investment in less than 14 months.