Core Differences in Automation: How Semi-Automatic and Fully Automatic Pallet Nailing Machines Work

Defining Semi-Automatic Pallet Nailing Machine Operations

Semi-automatic pallet nailing systems require operator involvement for tasks like board alignment and feeding. Workers manually place materials at designated stations, while the machine handles nail driving and reloading. This hybrid approach balances automation with human oversight, achieving output rates of 100–120 pallets/hour under standard conditions.

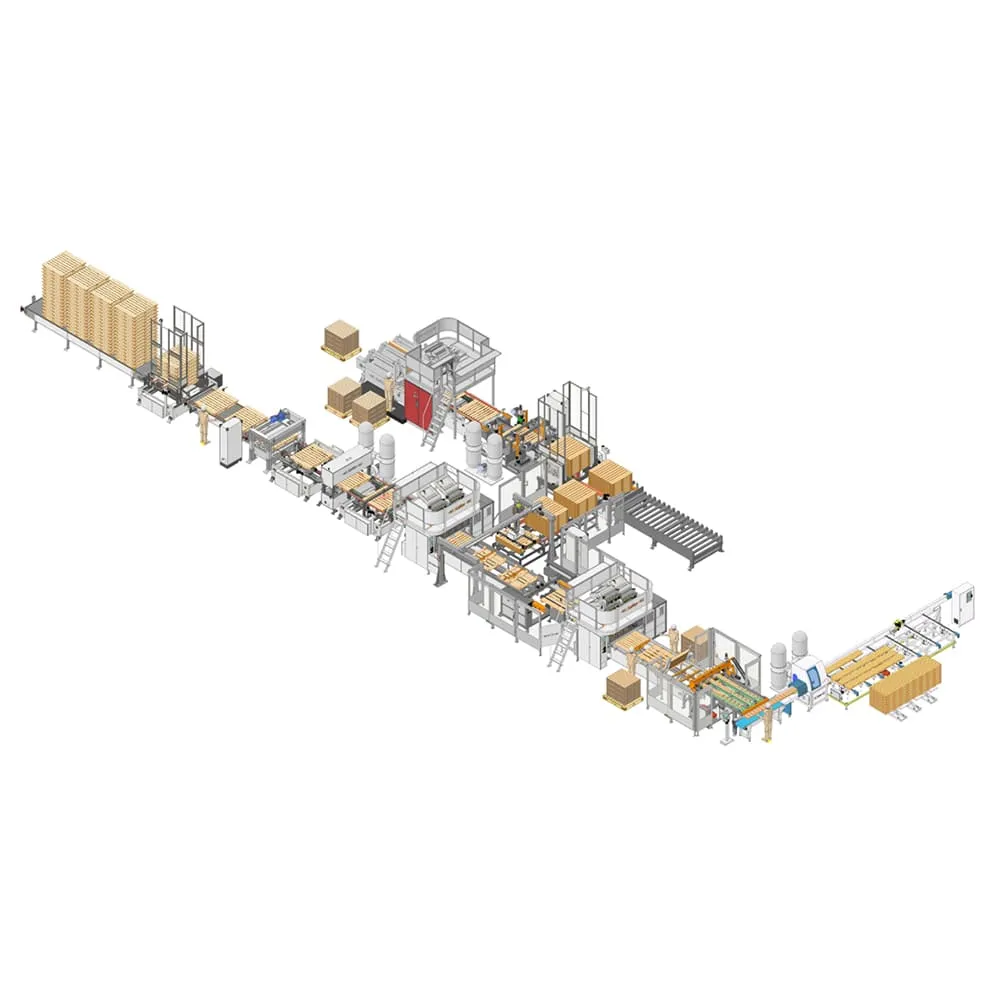

How Fully Automatic Pallet Nailing Machine Systems Function

Automatic systems these days basically take over all the manual work thanks to their built-in servo motors, PLC controls, and those handy robotic arms we see everywhere. The machines handle everything from positioning boards correctly to placing nails at impressive speeds around 4 per second, then stack the finished pallets without needing much supervision. Better versions come equipped with CNC guided alignment that keeps things accurate within half a millimeter or so. Most factories report they can crank out between 180 to 200 pallets each hour with very few mistakes happening along the way according to industry reports from last year.

Key Distinctions in Automation Levels and Human Intervention

The core differences between semi-automatic and fully automatic systems lie in labor needs, error correction, and operational continuity:

- Labor dependency: Semi-automatic lines typically require 2–3 operators per shift, whereas automated systems run with minimal supervision (0–1 personnel)

- Error correction: Fully automatic machines use laser sensors for real-time adjustments; semi-automatic units rely on manual recalibration

- Uptime: Automated lines support 22-hour daily operation, outperforming semi-automatic systems limited to ~16 hours due to operator fatigue

Production Capacity and Cycle Time: A Comparative Baseline

Automated nailing lines offer a 60–75% throughput advantage over semi-automatic setups. While semi-automatic systems produce one pallet every 30 seconds, automated configurations achieve cycle times as low as 18 seconds. Under sustained operation, automated systems maintain 95% efficiency even during 20+ hour shifts, while semi-automatic productivity drops by 15–20% due to human factors.

Efficiency and Throughput: Measuring Output Gains in Automated Nailing Systems

Measurable Efficiency Gains: Average Output Increase of 60–75% with Automation

Wood pallet nailing machines on production lines boost output significantly, typically between 60 to 75 percent more than when workers do it manually or with partially automated setups. The reason? These machines keep running nonstop without all the breaks people need for changing tools or moving materials around. Factory managers report seeing real money savings because there's less waste and fewer mistakes happening during mass production runs. Some recent studies point out that companies investing in full automation see their return on investment grow faster thanks to better material usage and those reduced error rates. Makes sense really when looking at large scale operations where even small improvements multiply across thousands of units.

Maximizing Throughput: Cycle Speed and Sustained Output in High-Volume Production

At peak performance, automated systems operate at 800–1,200 cycles/hour with ±2% speed consistency across continuous 24/7 runs. Real-time adjustments to nail depth and pressure ensure quality, while predictive maintenance algorithms schedule servicing without halting production. These capabilities enable long-term reliability and maximum uptime in demanding logistics and distribution settings.

Bottlenecks in Semi-Automatic Lines Under Continuous Operation

Semi-automatic systems lose 18–22% efficiency during extended shifts due to manual interventions for alignment, inspection, and jam clearing. Operators must stop production every 90–120 minutes for routine adjustments, accumulating up to 40 minutes of downtime daily at scale. These limitations make semi-automated lines less suitable for weekly outputs exceeding 5,000 pallets.

Labor Cost Savings and Workforce Transformation in Automatic Wood Pallet Nailing Making Machine Production Lines

Reducing Labor Costs in High-Volume Pallet Manufacturing

The numbers tell the story pretty clearly these days. Fully automated production setups slash labor costs somewhere around 70 to maybe even 85 percent when compared against traditional manual methods according to Industrial Automation Journal from last year. When we talk about what gets automated, think about all those boring repetitive jobs like moving boards into place, feeding nails through machinery, and checking for quality issues. With everything handled automatically, one person can actually manage anywhere from eight up to twelve different machines at once without breaking a sweat. Now look at semi-auto systems where each station still needs three to five workers standing around doing similar work. That means much bigger payroll costs and definitely not the same kind of cost effectiveness that full automation brings to the table.

Flexibility and Adaptability: Matching Pallet Production Lines to Business Needs

Semi-Automatic Systems for Small-Batch or Variable Pallet Production

Semi automatic nailing systems work really well for manufacturers who produce moderate volumes and need to switch products often. The operators get to tweak things like nail placement, how boards fit together, and pressure levels which matters a lot when making those custom or specialty pallets that come up so frequently. Companies that handle under 500 units each week find these systems pay off because they cut down on initial costs and boost productivity compared to doing everything by hand. Some studies suggest around 70% improvement in efficiency, though results vary depending on setup. What makes these machines stand out is their capacity to stop and change during production runs. This proves particularly handy in fields such as farming equipment manufacturing or pharmaceutical packaging where different seasons bring completely different size requirements for containers and crates.

Integration, Scalability, and Long-Term Growth in Modern Pallet Nailing Production Lines

Integrating Automatic Wood Pallet Nailing Making Machine Production Line with Existing Workflows

The modular approach makes it much easier to fit automated nailing systems into already running production lines without major disruptions. When these systems work well with existing conveyor belts, sorting machines, and quality check points, companies save around 30 to maybe even 40 percent on remodeling costs instead of replacing entire production lines from scratch according to industry reports from last year. The built-in monitoring system gives operators live updates showing how many nails are being used, when cycles go off track, and overall machine condition. Take the CNC guided alignment feature as one practical application. It adjusts itself automatically when dealing with planks of different thicknesses, keeping accuracy within about half a millimeter most of the time during regular operations.

Scalability Advantages of Fully Automatic Systems for Future Expansion

Fully automatic lines offer superior scalability through three core features:

- Production Capacity Elasticity: Adding parallel units increases output by 70–110% without expanding floor space

- Adaptive Software Architecture: Cloud-based controls enable instant deployment of new pallet specifications across multiple facilities

- Energy-Efficient Scaling: Smart power management reduces incremental energy costs by 18–22% per added unit

According to a 2023 Automation Scalability Study, facilities with fully automatic systems ramp up production 92% faster during peak seasons than those using semi-automatic setups. These systems also support future-ready upgrades such as AI-powered predictive maintenance and IoT-enabled tool monitoring—all without requiring hardware overhauls.

FAQ Section

What are the main advantages of fully automatic pallet nailing machines?

Fully automatic machines offer higher throughput, reduced labor costs, and enhanced efficiency due to minimal human intervention. They also support long-term growth and scalability with features like adaptive software architecture and energy-efficient scaling.

Can semi-automatic systems be cost-effective?

Yes, semi-automatic systems can be cost-effective for manufacturers producing moderate volumes or requiring frequent product switches. They provide flexibility and are suitable for operations handling under 500 units weekly.

How do automated systems improve operational safety?

Automated systems enhance safety by reducing the need for human interaction with dangerous components. Protective enclosures decrease injury rates significantly, and operators oversee processes from control panels.

Table of Contents

- Core Differences in Automation: How Semi-Automatic and Fully Automatic Pallet Nailing Machines Work

- Efficiency and Throughput: Measuring Output Gains in Automated Nailing Systems

- Labor Cost Savings and Workforce Transformation in Automatic Wood Pallet Nailing Making Machine Production Lines

- Flexibility and Adaptability: Matching Pallet Production Lines to Business Needs

-

Integration, Scalability, and Long-Term Growth in Modern Pallet Nailing Production Lines

- Integrating Automatic Wood Pallet Nailing Making Machine Production Line with Existing Workflows

- Scalability Advantages of Fully Automatic Systems for Future Expansion

- FAQ Section

- What are the main advantages of fully automatic pallet nailing machines?

- Can semi-automatic systems be cost-effective?

- How do automated systems improve operational safety?