The Evolution of Automatic Wood Pallet Nailing Machines: From Manual to Robotic Systems

Integrating robotics for precision and consistency in pallet assembly

Six-axis robotic arms equipped with vision-guided nailers now complete pallets in 3.2-second cycles, 15% faster than traditional automated lines. These systems maintain 99.4% fastener accuracy even with warped lumber, a feat unattainable with manual labor. This precision reduces quality control costs by 23% for high-volume operations.

Balancing upfront investment with long-term ROI in automation adoption

While automated nailing lines require 60–80% higher initial capital than manual setups, they cut labor costs by 42% within three years. The break-even point typically occurs at 22 months for mid-sized plants producing 800+ pallets daily, with energy-efficient servo motors slashing power consumption by 62% compared to hydraulic systems.

How automated nailing lines reduce human error and increase output speed

Automation eliminates 92% of alignment errors caused by fatigue in manual workflows. A single robotic cell produces 2,100 pallets per 8-hour shift—triple the output of a 5-person manual team. This scalability supports just-in-time manufacturing models while maintaining OSHA-compliant injury rates below 0.4 incidents per 100 workers.

Core Components of Fully Automated Pallet Nailing Lines

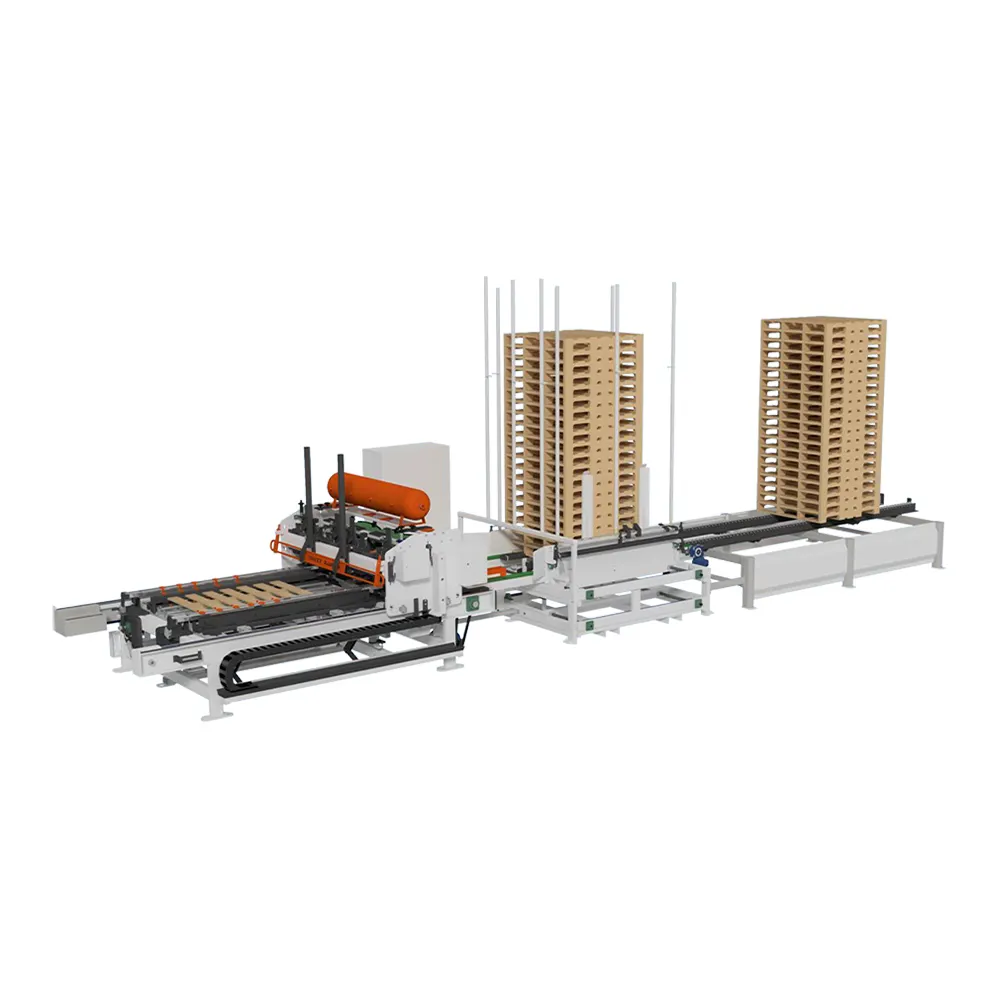

Synchronized Conveyor Systems for Seamless Material Flow

The core component of most automatic wood pallet nailing machines is actually a very carefully designed conveyor system. These systems handle all sorts of tasks at once - keeping track of where boards go, when clamps need to close, and what order nails should be driven in across several different stations. The result? Some pretty impressive production numbers, often pushing past 1,200 finished pallets during just an 8 hour workday. Specialized servo motors move the lumber through this whole process step by step: first feeding it into position, then aligning everything properly, followed by actual nailing operations, and finally getting those completed pallets ready for shipment. The level of precision here is remarkable too, staying within half a millimeter accuracy throughout. This kind of automation basically removes all those frustrating manual handling issues that used to slow things down so much.

Programmable Nail Patterns Enabling Rapid Customization

The system lets operators set up over 200 different nail pattern templates using those touchscreen PLC interfaces, covering standard EUR pallet blocks all the way through to totally custom designs. These dual mode actuators actually change out between 90mm spiral shank nails for softer woods and 70mm ring shank versions when working with hardwoods, and they do it all within just 8 seconds per cycle. What makes this so valuable is that manufacturers can move back and forth between ISO certified pallet formats and special order configurations without stopping production at all. That kind of seamless transition time is gold dust in just-in-time manufacturing setups where every minute counts.

Smart Tooling and Adaptive Manufacturing for Variable Wood Materials

Adaptive Clamping and Smart Tooling Interfaces for Inconsistent Lumber

The latest generation of automatic wood pallet nailing machines comes equipped with smart clamping systems designed to handle all sorts of lumber irregularities. These machines feature sensors that detect varying thicknesses and tweak grip strength along multiple axes at once. No need for constant readjustments when dealing with tricky pieces that have knots, splits, or just plain wonky shapes. What makes these systems so valuable is their ability to keep boards intact during assembly while still achieving pretty impressive placement accuracy around half a millimeter, even when working with cheaper, lower quality wood that would normally be a nightmare for traditional equipment.

IoT, Data Analytics, and AI in Automatic Wood Pallet Nailing Machine Performance

IoT-enabled remote monitoring and predictive maintenance

Modern automatic wood pallet nailing machines integrate IoT sensors to monitor vibration, temperature, and energy consumption in real time. This connectivity enables predictive maintenance by detecting component wear patterns before failures occur, reducing unplanned downtime by up to 18% in high-volume operations.

AI-driven models to minimize unplanned downtime

Machine learning algorithms analyze equipment performance data to forecast maintenance needs with 92% accuracy. Advanced models predict component degradation 7–10 days in advance, allowing manufacturers to schedule repairs during planned pauses without disrupting workflow continuity.

Optimizing nail usage and reducing waste through data analytics

Automated systems achieve 10–22% reductions in material waste by dynamically adjusting nail patterns based on wood density and load requirements. As detailed in recent material efficiency studies, pattern optimization delivers the highest savings with minimal implementation complexity compared to depth or material-specific adjustments.

Cyber-physical systems for on-demand custom pallet production

IoT-enabled machines synchronize with design software to produce custom pallet configurations in under 90 seconds. This capability eliminates manual retooling while maintaining structural integrity across 15+ standardized and bespoke designs.

FAQ Section

What are the advantages of using CNC-controlled nailing systems?

CNC-controlled nailing systems provide precise placement accuracy and significantly reduce material waste, accommodating various pallet designs with programmable settings.

How do robotic arms improve pallet assembly speed?

Robotic arms equipped with vision-guided nailers complete pallets faster than traditional automated lines, maintaining high fastener accuracy and reducing quality control costs.

What is the break-even point for investing in automated nailing lines?

For mid-sized plants producing over 800 pallets daily, the break-even point occurs at approximately 22 months, with substantial labor and energy cost savings thereafter.

Table of Contents

- The Evolution of Automatic Wood Pallet Nailing Machines: From Manual to Robotic Systems

- Core Components of Fully Automated Pallet Nailing Lines

- Smart Tooling and Adaptive Manufacturing for Variable Wood Materials

- IoT, Data Analytics, and AI in Automatic Wood Pallet Nailing Machine Performance

- FAQ Section