The Role of Automation in Modern Pallet Manufacturing

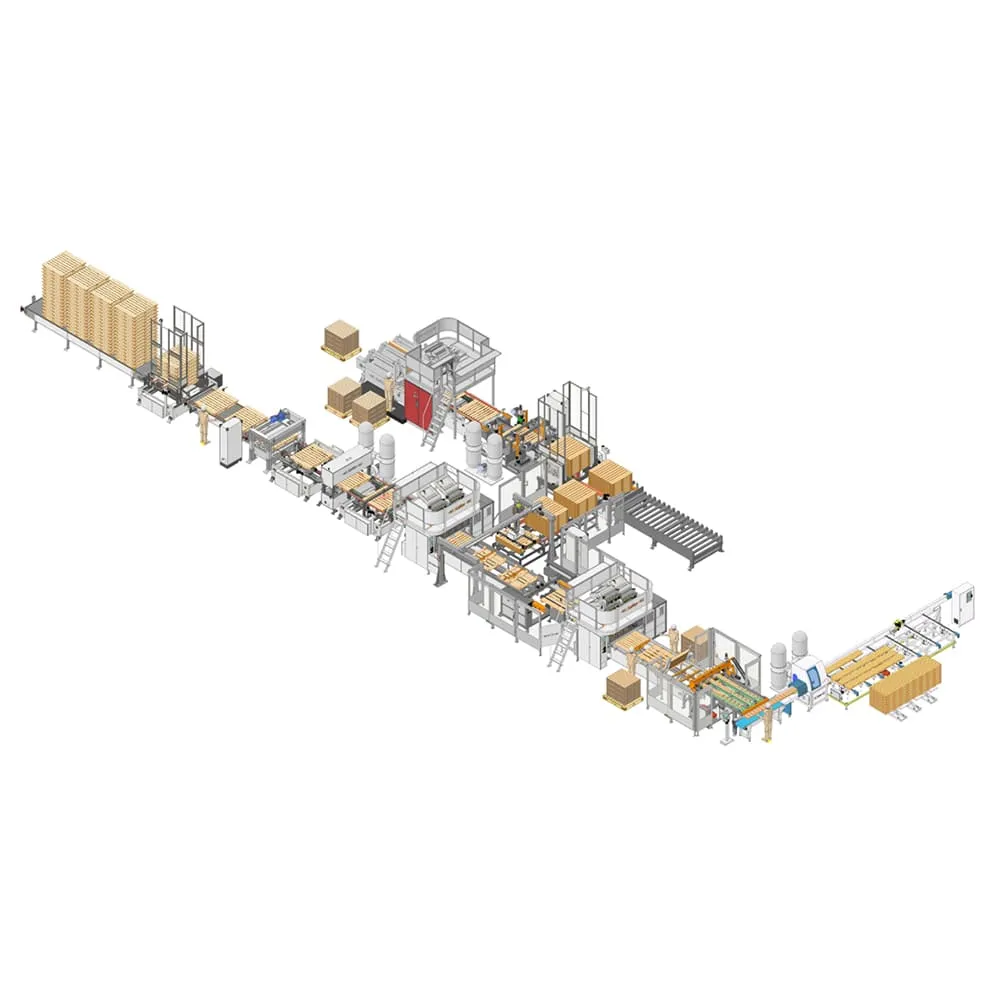

Today's pallet manufacturing operations rely heavily on automation, cranking out around 300 units every single hour with incredible precision down to fractions of a millimeter. According to PalletLab's latest research from 2023, this represents a massive jump in productivity—roughly seven times better than what workers could manage manually. The production lines themselves are controlled by PLC systems and consist of several components working together seamlessly. There are conveyor belts moving materials along, powerful robotic nail guns doing the actual assembly work, and advanced vision systems keeping everything aligned properly. These technologies combine forces to basically wipe out those pesky human errors when it comes to positioning stringers correctly and placing fasteners exactly where they need to go.

Common Challenges: Nail Placement Variability in High-Speed Lines

Even advanced systems face performance hurdles:

- Material Inconsistencies: Fluctuations in wood density lead to 12–18% nail deflection rates

- Synchronization Errors: A 0.1-second timing mismatch can result in 7–9 misplaced nails per minute

- Wear Compensation: Nail gun tips degrade by 0.02mm weekly, necessitating regular recalibration

Leading manufacturers mitigate these issues with real-time monitoring systems that dynamically adjust parameters mid-cycle, cutting scrap rates by 62% (Automation Quarterly 2023).

Optimizing Machine Performance for Precise Nail Placement

Key Factors Affecting Nail Pattern Consistency in Automated Lines

Material inconsistencies account for 38% of nail placement errors in automated pallet lines (PalletTech 2023). Three primary factors impact precision:

- Wood density variations: Hardwood vs. softwood stringers require dynamic pressure adjustments

- Machine alignment tolerances: Just 0.5mm misalignment in nailing heads increases defect rates by 12%

- Pneumatic pressure stability: Fluctuations beyond ±7 PSI disrupt penetration depth

Proper calibration—combining laser-guided positioning with humidity-compensating algorithms—reduces placement variability by 63%.

Advancements in Nail Gun Precision, Speed, and Synchronization

Modern servo-driven nail guns deliver 0.02mm repeatability at speeds up to 120 nails per minute—240% improvement over 2019 pneumatic models (IFPS 2024). Key innovations include:

- Self-adjusting driver heads that respond to wood grain irregularities

- Microsecond-level synchronization between feed mechanisms and nailing stations

- Predictive collision avoidance systems reducing misfires by 89%

These capabilities allow production lines to sustain 98.7% placement accuracy across mixed-material batches without manual intervention.

Integrating Real-Time Monitoring for Immediate Feedback and Correction

Vision-assisted quality control systems now detect nail protrusions as small as 0.3mm using 360-degree imaging. When integrated with PLCs, corrections are executed in <50ms—92% faster than human response times (Industrial Automation Journal 2023). This real-time feedback loop includes:

- Infrared sensors verifying nail depth during insertion

- Torque monitors analyzing driver head resistance

- Adaptive algorithms adjusting subsequent nailing patterns

This closed-loop approach reduces scrap rates by 41% and supports sustained output of 22 pallets/hour in 8-hour production tests.

How PLC Integration Enhances Automatic Pallet Nailing Machine Operation

The use of Programmable Logic Controllers, or PLCs for short, allows automatic wood pallet nailing systems to make on the fly changes to how deep nails go, their angles, and even the amount of force applied during installation. Some industry reports indicate that these PLC controlled systems can hit precision levels down to the micron range, which really matters when dealing with heavy loads over 2500 pounds without compromising structural strength. When factories swap out old fashioned manual adjustments for automated sensors and control logic, they tend to see dramatic improvements. One warehouse saw about a 90 something percent drop in those pesky alignment issues that used to plague them when they relied solely on compressed air systems back in the day.

Synchronizing Sensors and Actuators Through PLC Logic for Precision

The latest PLC systems work together with vision sensors, servo motors, and those nail feeders all inside just 5 milliseconds - that's about 40 times quicker than what we used to get from old school relay controls. The system stays so synced up it actually stops those annoying misfires that happen when dealing with tricky wood grains or when the conveyor belt isn't running perfectly smooth. Take pressure sensitive actuators for example. These little gadgets adjust how hard the nail gun hits whenever it runs into those tough hardwood knots. So even though the material gets harder in spots, the nails still go in properly without splitting the deck boards apart.

Case Study: Reducing Nail Misfires by 92% with PLC Firmware Upgrades

One pallet maker in North America cut down on rejected products by around 18,000 pieces each year once they installed PLC controlled quality checks that compare nail patterns to CAD designs. When they later upgraded their system with firmware that automatically adjusts for worn tools, things really took off. The mistake rate plummeted from nearly 9% all the way down to just 0.7% over half a year period. Plus, production cycles sped up by almost a quarter during this time. Looking at numbers from last year, we see these smart algorithms catch roughly 8 out of every 10 problems before bad pallets even make it to the curing area where they'd be wasted.

Implementing Predictive Maintenance for Long-Term Equipment Reliability

Impact of Wear and Tear on Nail Gun Performance Over Time

When machines run at high speeds for long periods, important parts like the nail feed system, guide rails, and driver blades start to show signs of wear over time. The constant friction between these components actually reduces their alignment precision by around 0.3 millimeters each year, which means nails aren't placed exactly where they should be. If operators don't address this gradual deterioration, things get worse pretty quickly. Misfires become much more common after just 1,000 hours of production work, jumping from normal levels to about 18% higher. This affects the structural integrity of the finished pallets and leads to more wasted materials on the factory floor. Maintenance teams need to keep a close eye on these wear patterns to maintain quality standards and reduce waste costs.

Reactive vs. Predictive Maintenance: Best Practices for Pallet Facilities

When companies rely on reactive maintenance, they typically face between 2 to 5 hours of unexpected downtime for each incident, and the repair bills tend to be around 2.7 times what they would cost if addressed through planned maintenance. On the other hand, predictive maintenance works differently. It uses sensors and some pretty advanced algorithms to spot when parts start showing signs of wear and tear. This lets technicians fix problems while everything else is running smoothly during regular maintenance windows. Shops that have switched to these predictive approaches often see about 40 percent fewer interruptions in their operations, plus their machines last roughly 22 percent longer overall. Take construction sites for instance where real time vibration monitoring can catch early signs of bearing issues in pneumatic nailers as much as three days before something actually breaks down, giving workers plenty of time to swap out worn components before major breakdowns occur.

Creating a Preventive Maintenance Schedule for Nailing Heads and Feed Systems

An effective, data-driven maintenance plan prioritizes:

- Nail heads: Replace driver blades every 50,000 cycles; clean ejection channels biweekly

- Feed systems: Inspect pneumatic pressure valves monthly; lubricate feeder chains every 500 operating hours

A 2023 implementation study found such schedules reduced unplanned downtime by 62% and maintained 98% equipment availability. Automated work order systems with PLC-integrated alerts further optimize task execution by aligning maintenance with natural production gaps.

Ensuring Pallet Quality and Automation Readiness Through Integrated Controls

Maintaining Uniform Build Quality Across Stringers and Deck Boards

Automated nailing heads perform best when supplied with components exhibiting less than 1% moisture variance and less than 0.5° angular deviation. Facilities utilizing real-time moisture sensors and automated board orientation systems experience 91% fewer alignment-related nail errors than those relying on manual inspection.

FAQ

What components are involved in automated pallet nailing systems?

Automatic wood pallet nailing systems consist of several key components, such as servo-driven rollers, pneumatic nail guns, laser sensors, Programmable Logic Controllers (PLCs), and real-time monitoring systems.

How does a PLC enhance the automation process?

PLCs allow for on-the-fly changes in nail depth, angle, and force. This helps in achieving greater precision and reducing alignment issues, improving overall process efficiency.

What are the common challenges faced by automated pallet nailing systems?

The systems often face challenges like material inconsistencies, synchronization errors, and wear compensation issues. Real-time monitoring systems are used to mitigate these challenges effectively.

What advancements have been made in modern nail guns?

Modern servo-driven nail guns boast repeatability of 0.02mm and can operate at speeds up to 120 nails per minute. Innovations include self-adjusting driver heads and predictive collision avoidance systems.

Why is predictive maintenance important for these systems?

Predictive maintenance helps identify early signs of wear and tear, reducing unexpected downtimes and increasing equipment lifespan by up to 22%. This proactive approach is more cost-effective than reactive maintenance.

Table of Contents

- The Role of Automation in Modern Pallet Manufacturing

- Common Challenges: Nail Placement Variability in High-Speed Lines

- Optimizing Machine Performance for Precise Nail Placement

- How PLC Integration Enhances Automatic Pallet Nailing Machine Operation

- Synchronizing Sensors and Actuators Through PLC Logic for Precision

- Case Study: Reducing Nail Misfires by 92% with PLC Firmware Upgrades

- Implementing Predictive Maintenance for Long-Term Equipment Reliability

- Ensuring Pallet Quality and Automation Readiness Through Integrated Controls

- FAQ