Irregular Curved Sanding Machine Replacement Rate

The composite doors can achieve a replacement rate of over 90%, but for solid wood doors, the difficulty is higher, and the irregular sanding machine can achieve 60% to 80% of the task.

Products Suitable for Processing by Irregular Sanding Machines:

1. Doors: Solid wood doors, composite doors, molded doors

2. Various furniture

3. Cabinet doors, windows

4. Complete home furnishings

5. Stairs, skateboards, picture frames, gift boxes, etc.

Application Standards for Processed Products:

The judgment of the processed product is based on whether it is below or above a flat surface.

Example: For doors, if the door panel is below the flat surface, it is called a flat door.

Flat door

If the door panel has raised lines above the flat surface, it is called a groove door.

Groove door

Sanding Range for Carving, Flat White Areas, and Painted Surfaces:

Shallow carving sanding range: within 10mm

Hollow sanding range: within 5mm

White area sanding range: within 30mm

Paint sanding range: within 20mm

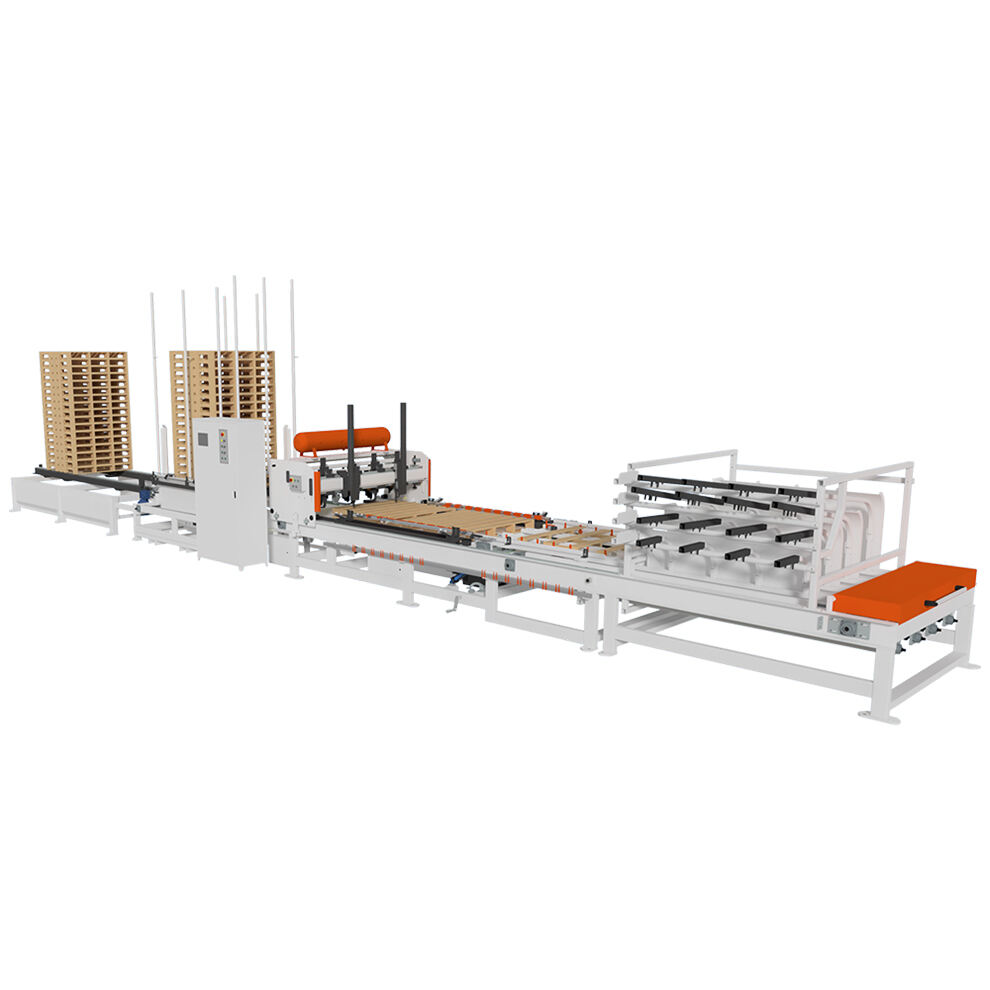

Functions of the Irregular Sanding Machine with Sanding Heads:

It is used to resolve the longitudinal and transverse sanding marks on the processed products.

Main Advantages of Kuimu Irregular Sanding Machine:

1. Overall lifting type: Two lifting devices are used. The first allows each sanding unit to lift as a whole, while the second allows individual units to lift separately, enhancing the sanding effect.

2. Modular design concept from abroad**: Each sanding unit adopts variable frequency speed control.

3. Equipped with an English touch screen.**

4. Each sanding unit is equipped with independent rotating and swinging machines.**

5. Each sanding unit uses imported high-precision linear guides** to ensure stable swinging.

6. Each sanding shaft is electronically controlled** for safety and convenience.

7. Quick sandpaper replacement** via numbers on the spiral shaft.

8. Each sanding unit is independent**, making it easier to collect dust and protect the machine’s lifespan.

9. Frame welded with overall profiles** to ensure the machine is more stable.

10. Each sanding unit displays thickness**, making operation convenient with an optional memory function.

11. Sanding roller’s left and right swinging** increases the sanding force, improving the sanding effect.

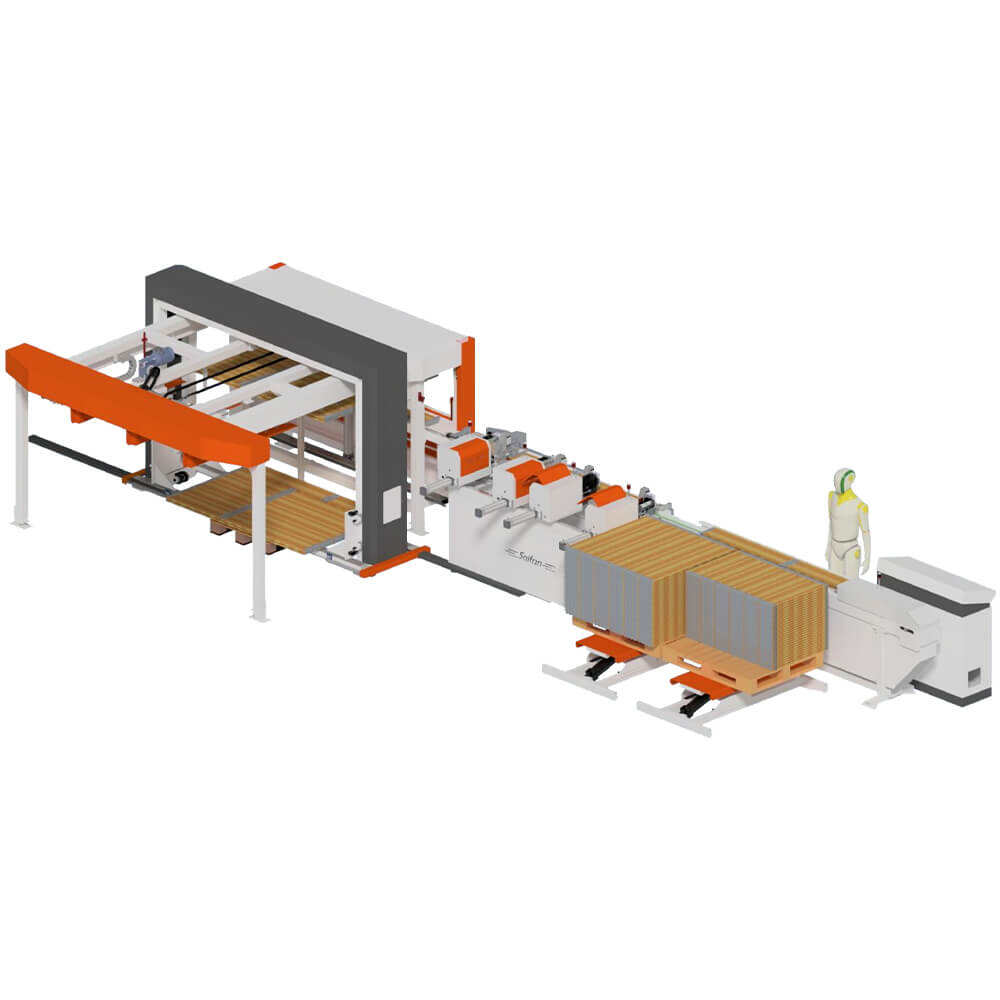

Three Types of Polishing Rollers in Kuimu Irregular Sanding Machine:

1. Longitudinal Shaft:

Each group has 4 rollers (total 8), which sand from left to right and right to left, providing excellent sanding results on chamfers and flat surfaces.

2. Transverse Spiral Roller Sanding Unit:

Each group has one spiral shaft (total 4), which sands from front to back and back to front. The spiral sanding system uses different types of sandpaper and sanding rotation directions for coarse and fine sanding. Using large diameter spiral rollers increases the contact area between the roller and the board, effectively solving the issue of vertical sanding marks on carved furniture parts and cabinet doors. This system is suitable for wooden doors, cabinet doors, shutters, furniture, picture frames, carved furniture parts, and improves work efficiency.

3. Disc Brush:

Using our company's innovative design with a patented disc brush rotating sanding unit, the large disc drives the small disc, using both self-rotation and 360-degree sanding. It features quick-detach technology for easy equipment replacement and offers better independence. Compared to traditional sanding systems on the market, this system provides cleaner and more even sanding, with excellent results on grooves. This is one of the standout advantages of our equipment.

Hot News

Hot News