Sanding and Polishing Equipment for Wooden Door Production

Sanding technology is a widely used processing technique in today’s wooden door and furniture manufacturing industries. It is not only used for thicknessing engineered wood and solid wood components but also for fine sanding of veneer faces and paint films, improving product quality, enhancing decorative effects, and saving costs.

Various types of machinery are used for sanding. The commonly used equipment for sanding wooden doors includes: handheld sanders, narrow belt sanders, irregular multifunctional sanders, and wide belt sanders.

|

Handheld Sanding Machine

|

Narrow Belt Sander

|

Handheld Sanding Machine

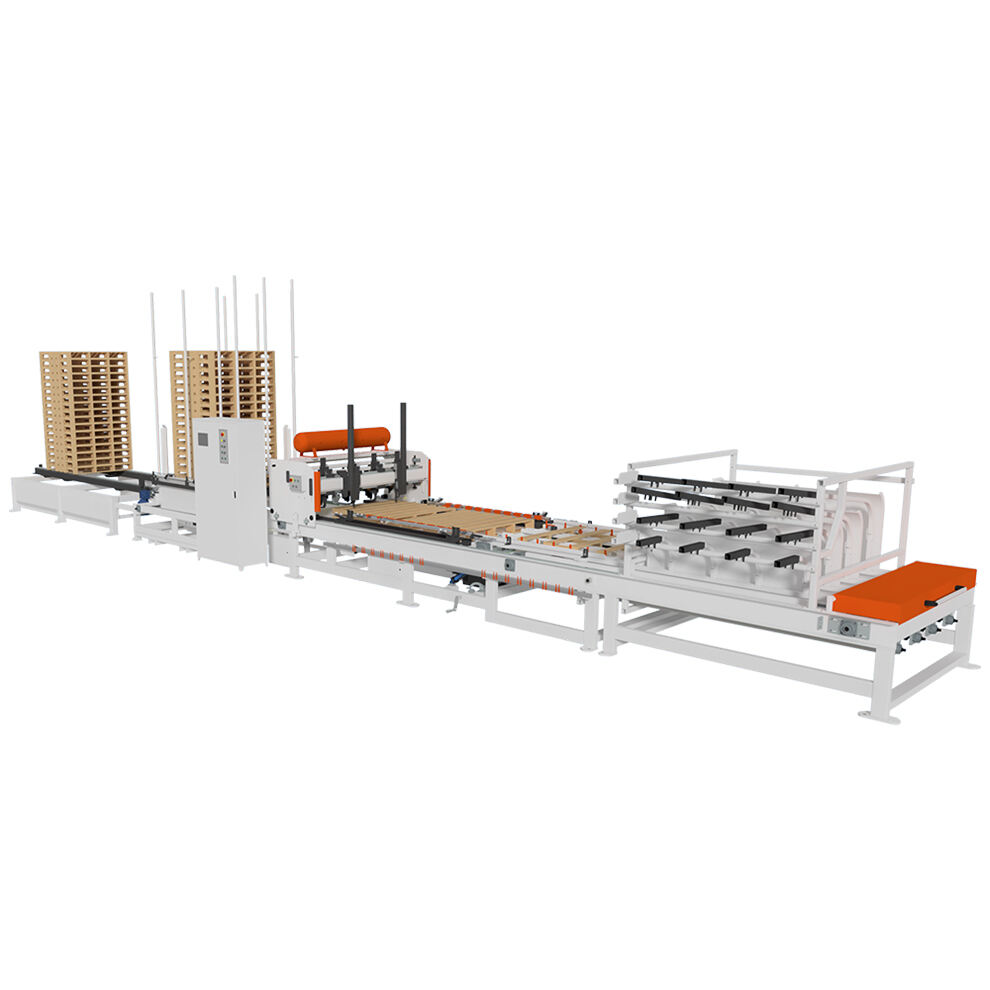

Due to its flexibility and efficiency, the handheld sanding machine holds an irreplaceable position in many industries. However, over long-term use, it poses certain labor intensity and environmental impact issues. To effectively reduce these problems, automated equipment can replace handheld sanders, as shown below:

|

Sanding Machine

|

Internal images

|

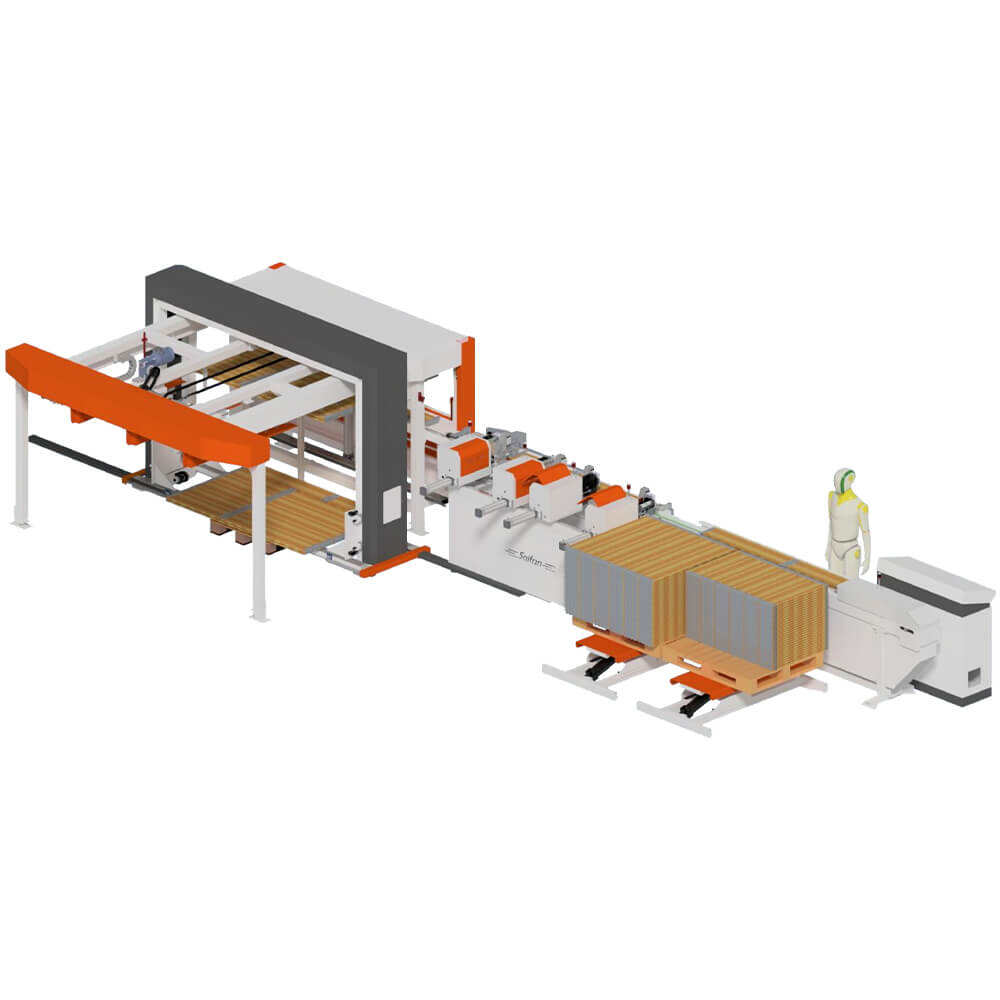

Sanding Machine

The sanding machine is designed for primer sanding, suitable for resin paints, polyester paints, water-based paints, PV, PU, PE, melamine, and other primers. The sanding rollers are raised and lowered by a servo motor, and the height of each sanding roller can be precisely controlled via PLC. The control system adopts an industrial computer, ensuring accuracy and durability.

The sanding machine uses an upward-floating design with a conveyor speed of 4-30 meters/min. The vacuum adsorption conveyor belt and pressure wheel design ensure the sanding effect.

The control screen uses a true color screen, making operation simpler and more intuitive.

|

irregular multifunctional sander

|

Internal images

|

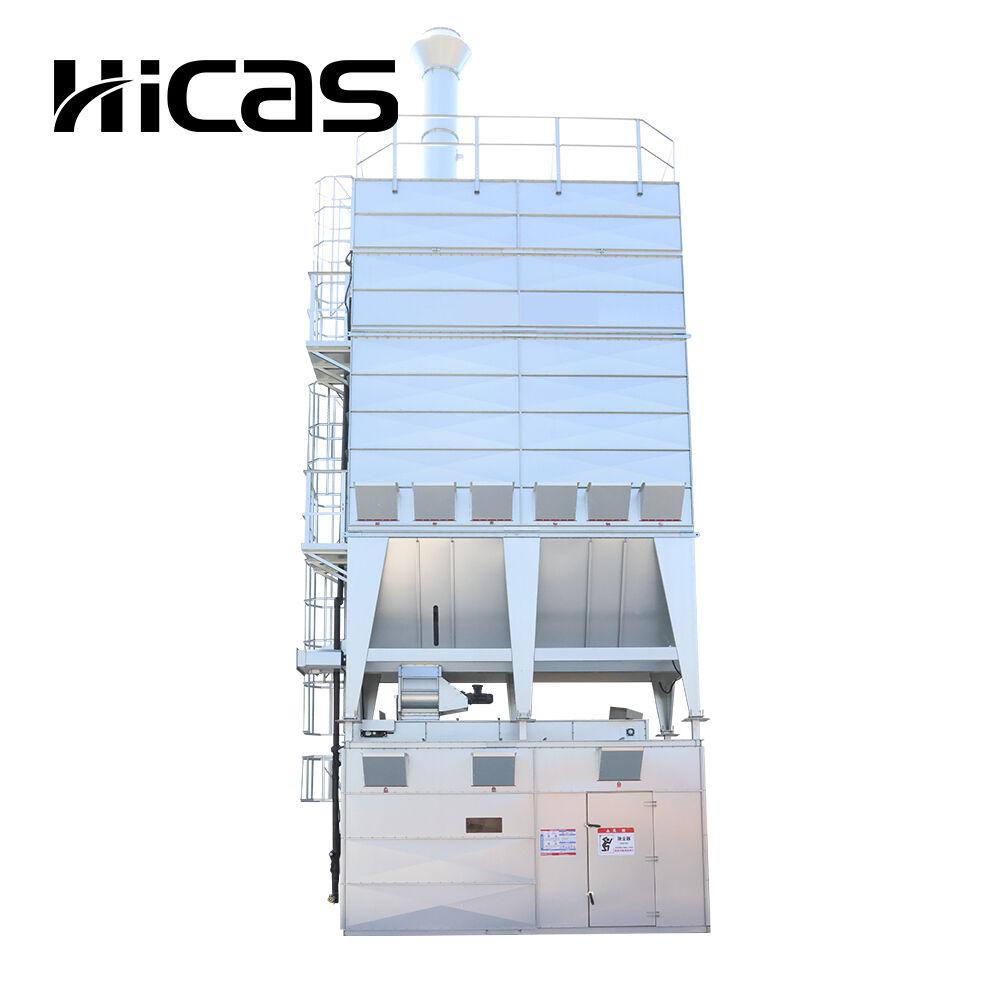

Irregular Sanding Machine

This machine is specifically designed for polishing curved surfaces of indoor doors, cabinet doors, furniture, and other shapes. It handles the surface treatment of solid boards, colored boards, and primers. It performs well on irregular workpieces, improving production efficiency.

It can apply various types of paints, such as PU, UV, and water-based paints, with coating thickness controlled within 5-10g/m².

The control electrical box is separated.

The anti-collision design includes a feeding guard plate protection device, preventing damage to the coating rollers when the board deforms.

Handheld sanders and narrow belt sanders are commonly used for small batch production, while irregular multifunctional sanders and wide belt sanders are suitable for large batch production. The primary function of the irregular multifunctional sanding machine is to address the uneven sanding surfaces of wooden doors, providing irregular polishing. Additionally, vertical sanding heads can be added on both sides of the equipment, enabling simultaneous sanding of the door surface and sides, effectively avoiding repetitive labor and greatly saving on manpower. This machine is especially suitable for sanding solid boards and painted surfaces, with particularly excellent results for painted surfaces. The wide belt sander is mainly used for sanding large flat surfaces of solid wood composite doors.

Choosing the appropriate equipment depends on the factory’s scale, processing tasks, workpiece characteristics, production capacity, and economic conditions. This ensures the improvement of product quality, product grade, and cost reduction.

Hot News

Hot News