Technical Specifications

Steel Belt Specifications: 50 × 0.7 mm (custom sizes available)

Hole Diameter: φ18 mm

Compatible Wood Thickness: 5–10 mm

Production Efficiency: 10,000–12,000 staples per 8-hour shift

Control System: Siemens PLC with touchscreen program control

Total Installed Power: 6 kW

Processing Accuracy: ±1 mm

Overall Dimensions: 3500 × 5000 × 1500 mm

Total Weight: Approximately 1.1 tons

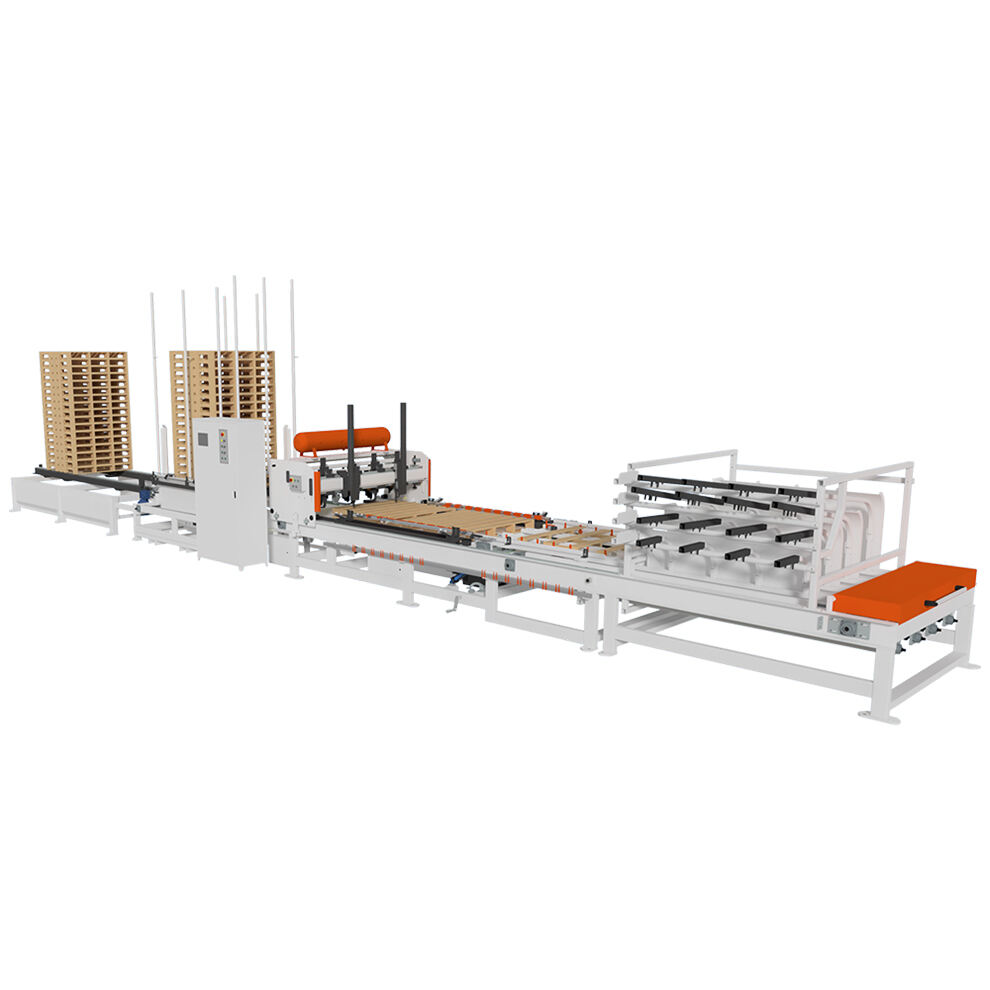

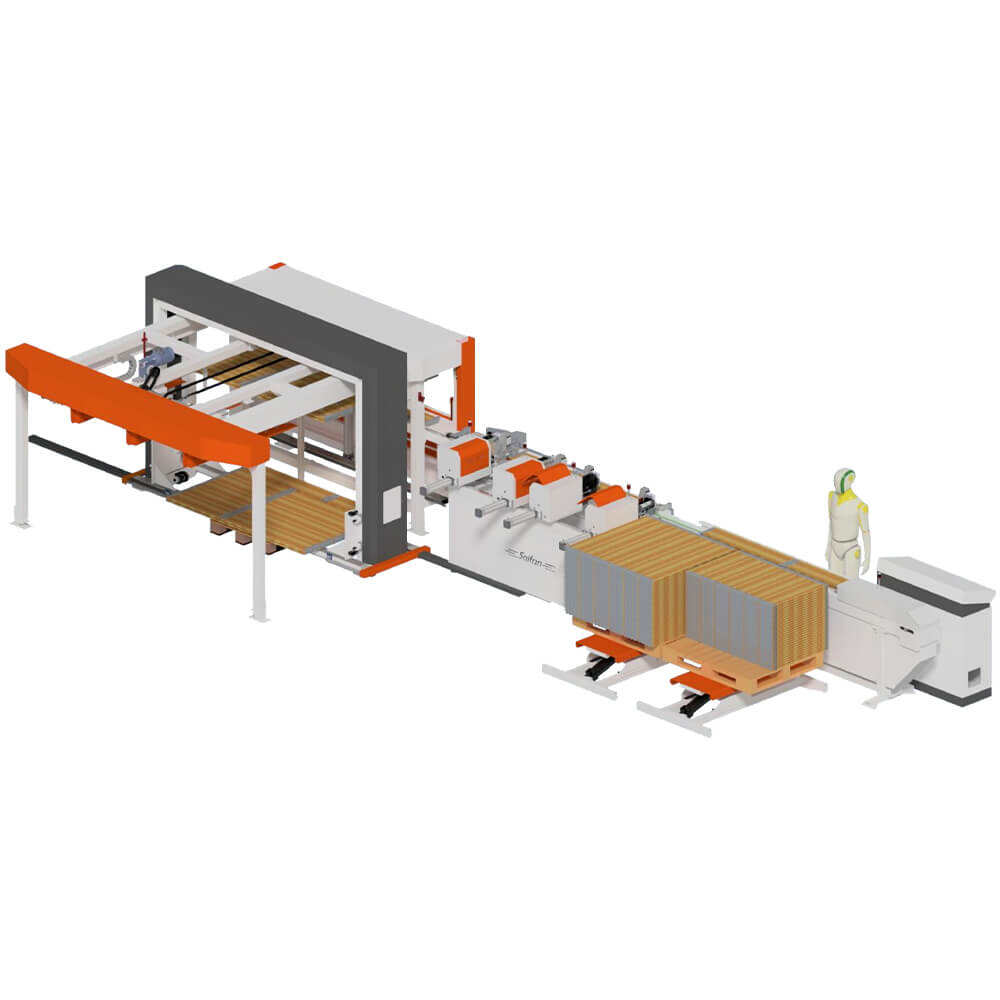

Nail-less Box Stapling Machine Overview

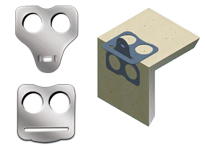

The Nail-less Box Stapling Machine is a core piece of equipment for manufacturing nail-less steel-belted wooden boxes, also known as quick-assembly boxes or inserted-plate wooden boxes. The machine integrates steel belts with specialized locking clips to enable rapid box assembly and convenient disassembly.

This solution is widely adopted in logistics, export packaging, and industrial manufacturing due to its environmental friendliness, reusability, and significant labor savings. Within the industry, this equipment is commonly referred to as a stapling machine, nail stapler, locking stapler, steel stapler, or nail-less box equipment. The technology is mature and supported by multiple suppliers offering customized configurations.

Application Scenarios and Industry Use

Export Packaging

Because the packaging does not require fumigation treatment, it complies with International Plant Protection Convention (IPPC) standards. This makes it especially suitable for export packaging of machinery, equipment, and high-value goods.

Logistics and Storage

The machine is used to produce reusable, quick-assembly wooden boxes and foldable containers. These boxes can be easily disassembled, stored flat, and reused, improving warehouse efficiency and reducing logistics costs.

High-End Manufacturing

It is well suited for packaging precision instruments, household appliances, hardware components, and other products that require strong protection against impact, deformation, and corrosion.

Food and Pharmaceutical Industries

By eliminating iron nails, the risk of metal contamination is reduced. This supports compliance with GMP and other clean-environment standards required in food and pharmaceutical packaging.

Energy Efficiency and Environmental Performance

The machine features a sealed structural design and brushless motor systems, which help minimize noise and dust emissions during operation. Selected configurations can be equipped with vacuum dust collection systems to further improve workshop cleanliness.

Compared with traditional hydraulic or nail-based equipment, this solution operates with lower energy consumption and without welding, riveting, or similar high-pollution processes. As a result, there is no smoke or exhaust gas generation, supporting clean and sustainable production.

Core Advantages

Material Savings

The system completely eliminates the need for traditional iron clips and steel nails. A single machine can save more than 100,000 iron clips annually.

Joint lengths are typically 40–80 mm shorter per connection compared with traditional buckle straps, directly reducing steel belt or PET strap consumption.

Finished wooden boxes are reusable, extending their service life and significantly lowering raw material demand.

Energy Efficiency and Environmental Protection

The servo-based control system ensures precise motion control and stable performance. Compared with older hydraulic systems, it operates with lower power consumption and produces no dust during normal operation.

The absence of welding and riveting processes avoids smoke and waste gas emissions, ensuring compliance with modern environmental and clean-production standards.

High Automation and Productivity

The machine is designed for single-operator use, with a high level of automation that reduces labor requirements.

Fast forming and stapling cycles significantly improve packaging efficiency, shorten production time, and indirectly reduce energy consumption per unit produced.

Hot News

Hot News