|

|

|

| Double-Sided Production |

Digital Control |

Technical Specifications

Steel Belt Specifications: 80 × 0.7 mm (custom sizes available)

Tooth Length: 9.5 mm

Compatible Wood Thickness: 5–10 mm

Control System: PLC + industrial computer with dedicated Porket2023 software

Production Efficiency: 4,000–4,500 meters per 8-hour shift

Total Installed Power: 6 kW

Number of Forming Wheels: 10 sets

Processing Accuracy: ±1 mm

Steel Belt Distribution: 20 × 20 mm

Machine Dimensions: 3200 × 1100 × 1450 mm

Total Weight: Approximately 1.15 tons

Single Steel Belt Machine SF3103

Steel Belt Production

CNC Operation

Technical Specifications

Steel Belt Specifications: 42 × 0.7 mm (custom sizes available)

Tooth Length: 9.5 mm

Compatible Wood Thickness: 5–10 mm

Control System: PLC + industrial computer with dedicated Porket2023 software

Production Efficiency: 2,200–2,500 meters per 8-hour shift

Total Installed Power: 6 kW

Number of Forming Wheels: 10 sets

Processing Accuracy: ±1 mm

Steel Belt Distribution: 20 × 22 mm

Machine Dimensions: 3200 × 1100 × 1450 mm

Total Weight: Approximately 1.15 tons

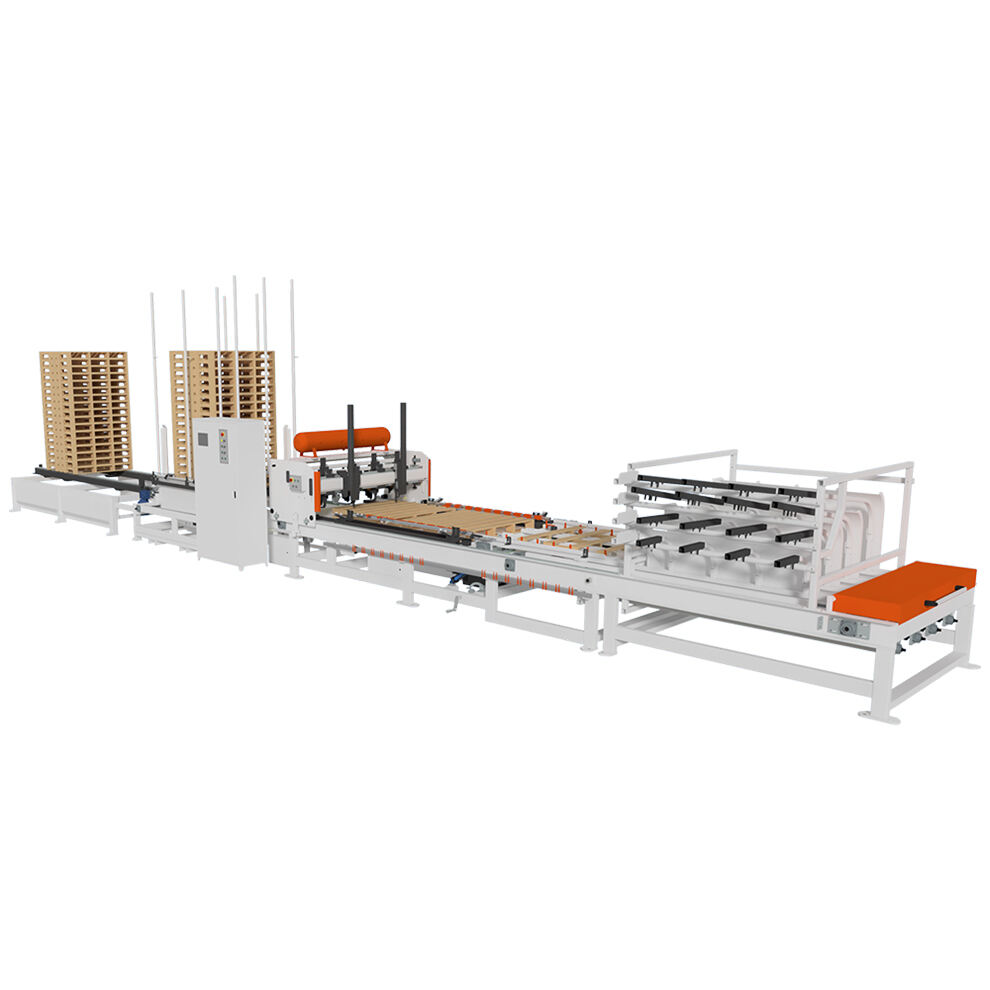

Nail-less Box Steel Belt Machine Overview

The Nail-less Box Steel Belt Machine is designed for the automated production of nail-less steel-belted wooden packaging boxes. It enables high-efficiency manufacturing with reduced labor input and precise dimensional control. This equipment is also commonly known as a nail-less packaging box steel belt machine or a wooden box steel belt edge banding machine.

The machine forms and wraps metal steel belts around the edges of plywood boxes and locks them securely in place, completely eliminating the need for traditional nails. This design allows for rapid assembly and convenient disassembly, making the finished boxes reusable, non-heat-treated, and suitable for export packaging applications.

The system is widely used in export packaging, logistics, and industrial transport, particularly where compliance with international shipping standards and environmental requirements is critical.

Core Features and Technical Characteristics

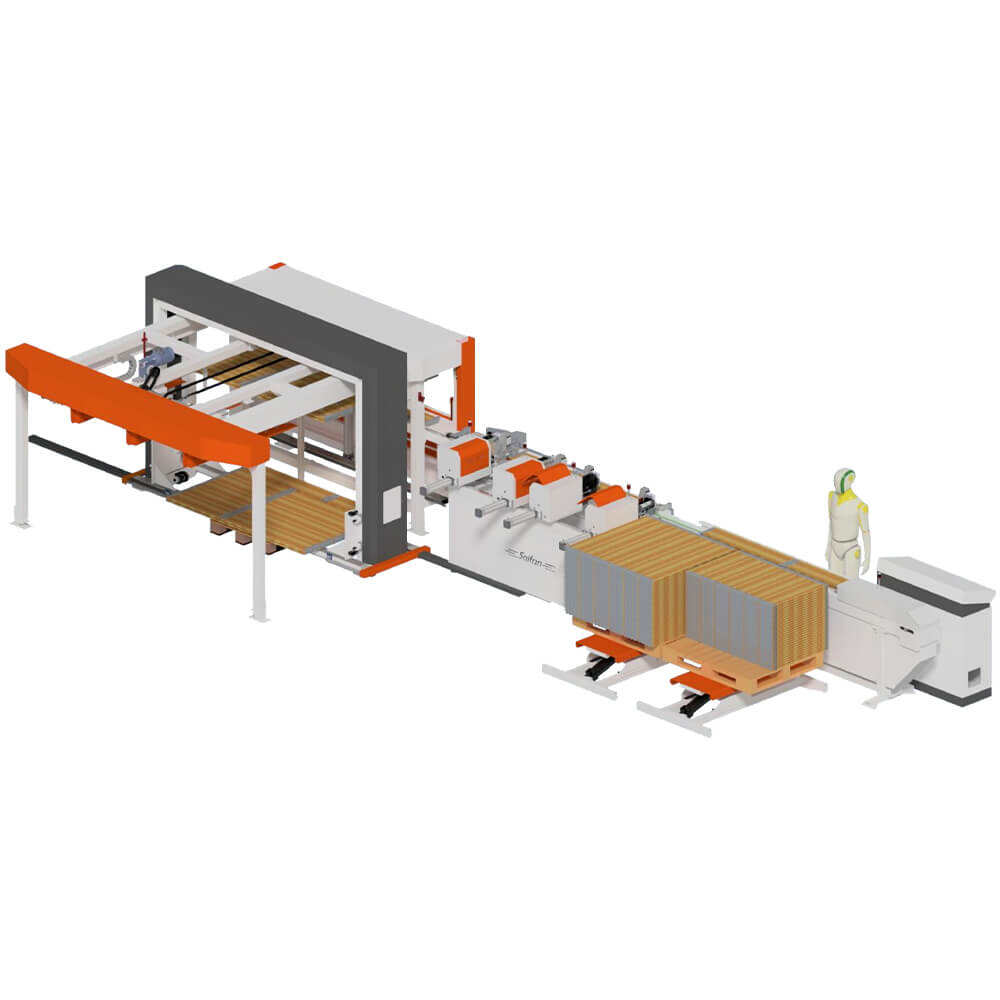

High Automation and Ease of Operation

The machine supports fully automated operation through a touchscreen-based control interface. One-click start functions allow operators with varying skill levels to manage production efficiently, and a single operator can typically oversee the entire process.

Durable Forming Molds

The forming molds are manufactured from high-strength steel materials, offering excellent wear resistance. This design minimizes deformation, reduces oil leakage risk, and significantly extends the service life of the molds and the overall machine.

Intelligent Software Management

Equipped with dedicated control software, certain models support advanced production planning functions. Operators can preset production schedules ranging from one day to one week, quickly switch between different steel belt specifications, and reduce material waste caused by frequent manual adjustments.

Energy-Efficient and Stable System Design

The optimized hydraulic and servo-driven systems ensure stable operation with low energy consumption. Enhanced heat dissipation and oil circulation designs prevent overheating and leakage, allowing the equipment to support long-term, 24-hour continuous operation with high reliability.

Hot News

Hot News