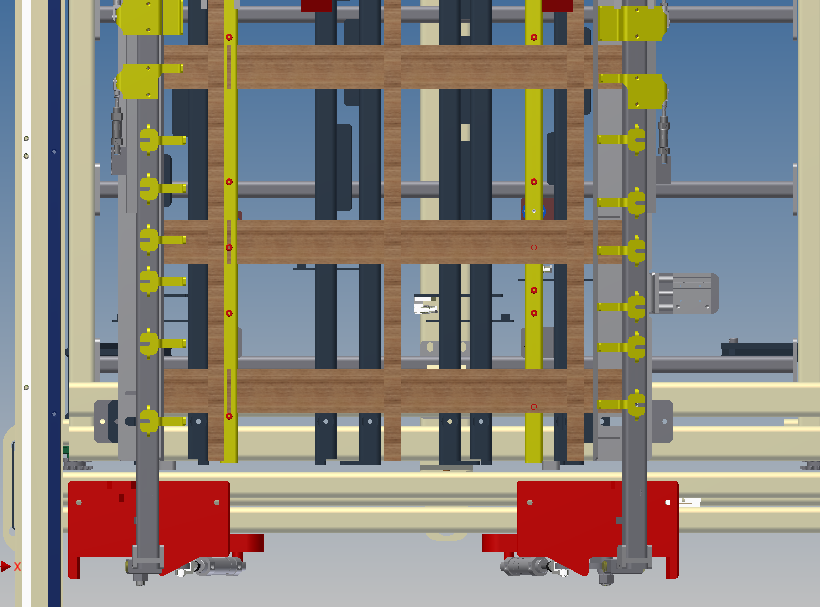

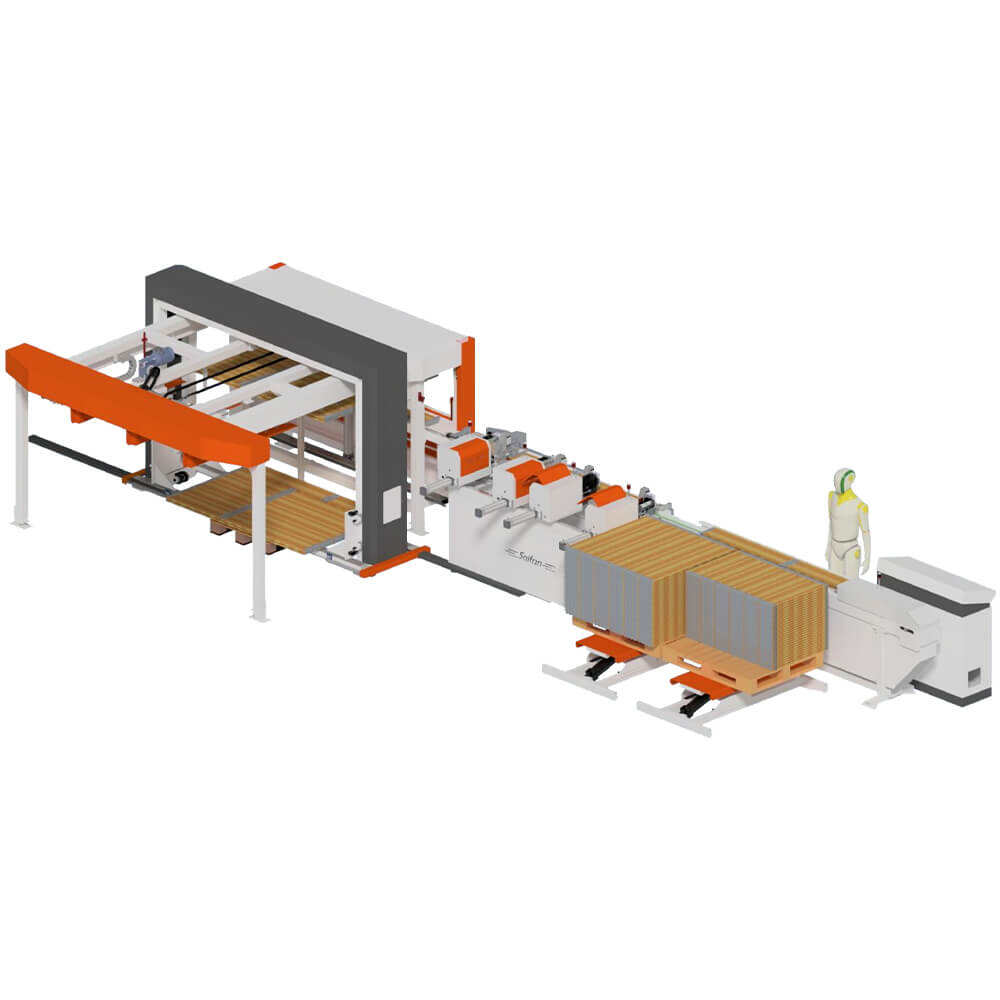

Adjust the mold and nail gun position according to the actual size of the pallet. Try not to adjust the mold and nail gun on the side close to the electrical box. The procedure for adjusting the specifications is as follows:

1. Loosen the fastening screws at both ends of the mold, move the mold to the required position, and ensure that the mold is vertical and not skewed.

2. After adjusting the mold position, tighten the screws.

3. Place the longitudinal beam into the mold, press the wooden material tightening button to clamp the longitudinal beam. At this point, the positioning plate of the longitudinal beam base will rise, and the base plate will be placed into the mold.

4. Set the overhead crane switch on the main electrical cabinet to "manual", and press the "crane forward" button on the control panel to move the crane near the edge of the pallet. Then loosen the tightening screws on the top of the nail gun bracket and the front of the nail gun, as well as the tightening screws on the top of the nail magazine. Adjust the position of the nail gun and nail magazine, making sure the nail gun nozzle is aligned with the center of the pallet's longitudinal beam. Tighten the screws.

5. Adjust the nail gun height:

(1) Loosen the handle bolts on both sides of the crane. Using the tool provided at the time of delivery, rotate as shown in the diagram. Turn clockwise to raise and counterclockwise to lower. Adjust the nail gun so that its protective cover is close to the bottom plate of the pallet. Once adjusted, tighten the handle bolts again.

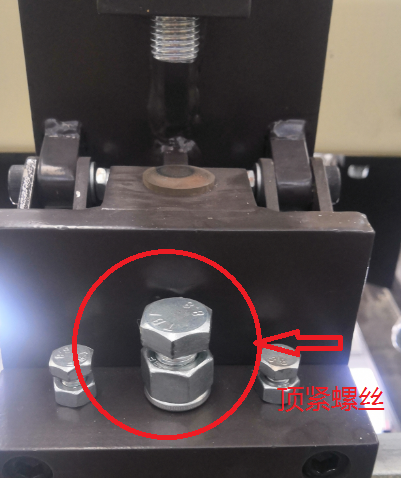

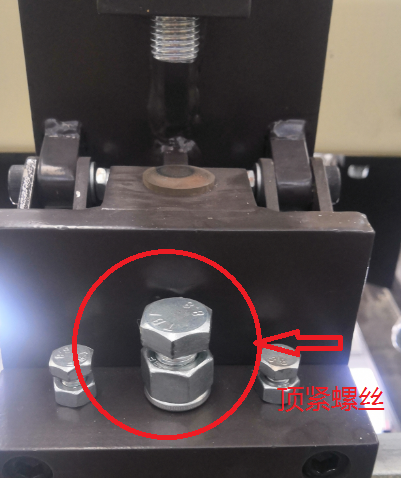

(2) If the nail gun cannot reach the required position even after raising it to the highest setting, adjust the top bolts on the nail gun bracket as shown in the diagram. Turn clockwise to raise and counterclockwise to lower the nail gun. After adjusting, tighten the locking screws.

Note: After adjusting the nail gun, move the crane back and forth once to check if the nail gun and the reverse nail groove interfere with the mold.

6. Start Nailing:

(1) Set the switch on the control panel to "automatic," press "nail servo reset," and once the crane returns to zero, prepare the panel. Press the "nail start" button on the crane to begin work.

(2) During the nailing process, if any unexpected situation occurs, press the emergency "pause" button located at the front of the crane. After resolving the issue, press the reset button to resume the machine’s operation.

(3) If the emergency stop button is pressed, after handling the situation, the crane needs to be reset to zero, and the pallet production must restart.

Hot News

Hot News