Understanding Flexible Adjustment Mechanisms

1. Core Components Enabling Multi-Pallet Adaptability

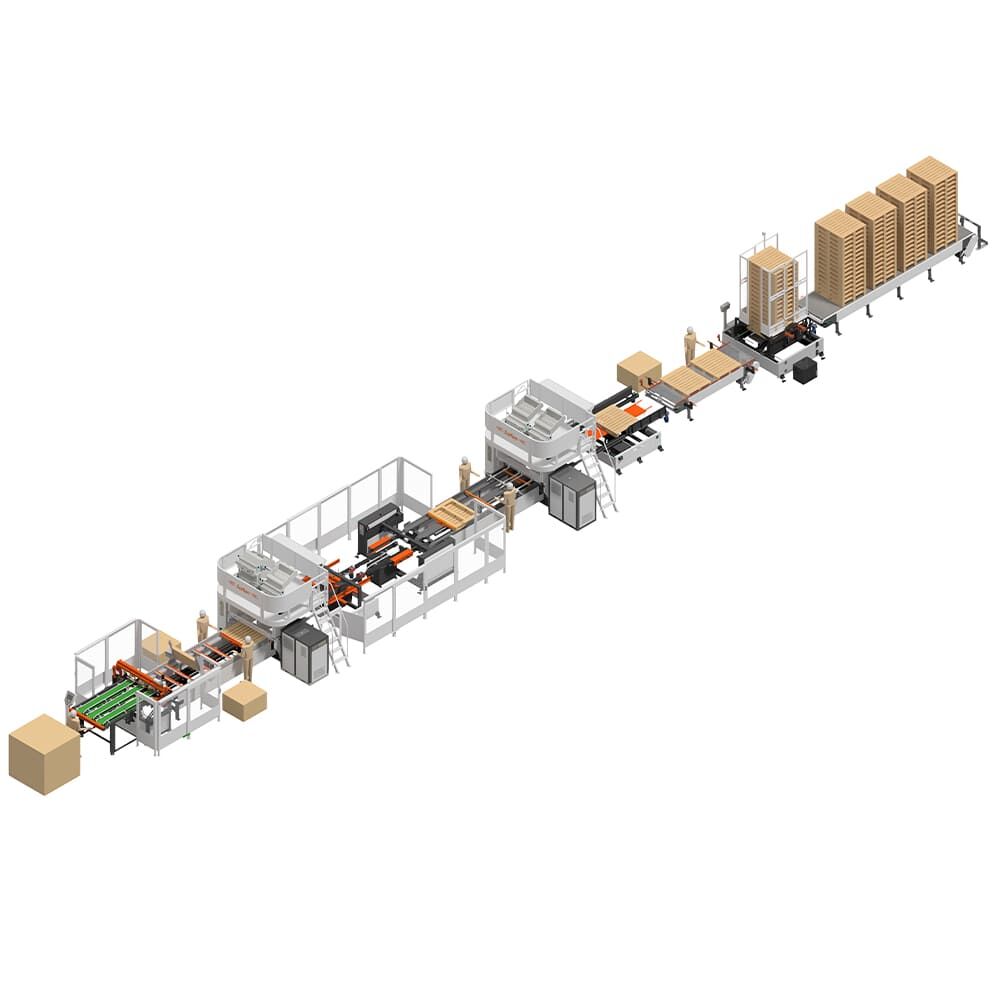

Woodworking machines with flexible adjustment features really boost what shops can produce because they come with things like adjustable frames and those modular attachments everyone talks about. The whole point is these parts let manufacturers handle all sorts of different pallet sizes and shapes without breaking a sweat. That kind of flexibility means shops can switch between projects quickly when customers ask for something unexpected. Some numbers floating around show that getting these adjustable systems into place might actually increase productivity by as much as 30 percent. Makes sense too since being able to tweak equipment on the fly saves time and money across the board for most manufacturers trying to stay competitive in today's market.

2. Role of Modular Jigging Systems

Modular jig systems are really important for getting things aligned properly when making adjustments to pallets on woodworking machines. Woodworkers can pick from different kinds of jigs depending on what they need to do. Some help create those straight, even edges every time while others handle oddball shapes or custom sizes that just won't fit any standard template. People who spend hours online discussing woodwork talk about how these modular setups cut down on mistakes during assembly. That matters a lot because nobody wants their project ruined by something going off track midway through. Beyond better accuracy, these systems actually save time too. Workflows become smoother and faster once everything clicks into place correctly from the start, so shops end up producing more finished pieces without sacrificing quality.

3. CNC Controls for Precision Configurations

Woodworking shops rely heavily on CNC controls to get those fine adjustments right when working with nailing machines. These systems let operators set things up with pinpoint accuracy, which means every piece coming off the line looks pretty much the same. Shops that have adopted CNC tech report better results across the board. Take custom panel makers for instance they need those measurements spot on or their panels just won't fit together properly. What makes CNC so valuable is how it works alongside regular tools. It brings automation into the mix without replacing the skilled hands that know what works best. This combination allows woodworkers to tackle complex designs while still maintaining that reliable performance needed for serious projects.

Step-by-Step Adjustment Process

1. Preparing Machine for Pallet Type Switching

Getting ready for a pallet type changeover requires sticking to certain procedures if we want to keep things safe and accurate around here. Start by doing those safety checks first thing - look out for anything that might be dangerous or broken parts that need replacing. Makes sense really, because this kind of maintenance keeps everyone working safely and actually extends how long the machines last before needing repairs. Next step after checking safety is getting everything calibrated properly so it matches up with whatever new pallet sizes are coming through. Most shops will tell us this matters a lot since skipping these basics just leads to more problems down the line when machines stop working right. What do we need? Basic hand tools mostly: wrenches of different sizes, good quality screwdrivers, maybe even some specialized calibration gear depending on what exactly needs adjusting. These little details matter when dealing with different designs over time. Following all this stuff isn't just good practice, it's pretty much standard across woodworking operations looking to maintain both efficiency and safety standards.

2. Adjusting Nail Depth and Spacing Parameters

Getting the right nail depth and spacing makes all the difference when building sturdy pallets. When nails are properly placed at correct depths, they help the pallet hold up under heavy loads without wobbling or breaking apart. To get the depth right, most woodworkers grab some measuring tools first before driving those nails in too deep or shallow. The type of wood matters here too since denser materials need different treatment than softer ones. Spacing between nails should be pretty even across the whole pallet frame so nothing feels off balance later on. Industry pros who've been working with wood for years always stress checking everything over regularly. They see problems like nails sticking out unevenly or not going in far enough all the time. Sticking to consistent patterns just makes sense if anyone wants their pallets lasting longer and holding together better through rough handling.

3. Calibrating Feed Systems for Different Wood Thicknesses

The thickness of wood being processed really affects how well the feed system is calibrated, so getting this right matters a lot for production. When calibrating, operators need to tweak both the feed speed and pressure settings based on what kind of thickness they're dealing with. This helps keep things running smoothly and stops those annoying jams that waste time and materials. Begin by measuring the wood carefully using good quality tools, then input those numbers into the machine's control panel to get proper calibration settings. Many woodworking shops talk about how important this process is, pointing out better results and less wasted stock as major advantages. Following through with these calibration steps makes sure machines run at their best, delivers consistent product quality across batches, and ultimately saves money by making better use of available raw materials.

Calibration Techniques for Precision

1. Laser Alignment for Deck Board Positioning

Laser alignment tech makes all the difference when it comes to getting those deck boards positioned just right during assembly work. When manufacturers use these laser systems, they get much better consistency across their production runs. The boards end up in exactly the spot they need to be, which means stronger joints and overall better quality products coming off the line. Setting up these laser systems properly takes some know-how. First things first, installers need to mount the lasers at precisely the right height relative to the work surface. Then there's fine tuning required so the beam lines up perfectly with each individual board as it moves through the assembly station. Getting this right from day one saves headaches down the road when trying to troubleshoot misaligned components later on.

2. Optimizing Pneumatic Pressure Settings

Getting a handle on how pneumatic pressure settings affect machine performance makes all the difference when it comes to running operations efficiently. When set correctly, these pressure parameters actually boost production rates because machines run smoother without fighting against unnecessary force or friction. To get things just right, most facilities spend time experimenting with different pressure levels across their various processes until they strike that sweet spot where everything works at peak capacity. Factory managers report seeing real gains after fine tuning these systems too many times to count. Some plants have clocked anywhere from 15% to 30% increases in output once they got the pressure calibrated properly, plus they tend to save money on energy costs over time as well.

3. Fine-Tuning Angle Grinders for Specialty Cuts

Getting angle grinders set up right makes all the difference when doing those specialty cuts that need to fit exact measurements. Woodworkers should tweak things like how the grinding wheel sits at an angle, what speed they run it on, and where the handles are positioned based on what kind of cut they actually need to make. Most experienced craftsmen will tell anyone who listens that checking these adjustable parts regularly keeps everything running smoothly and safely over time. When folks take the time to follow this advice, their cuts end up cleaner, straighter, and faster than if they just wing it. This attention to detail really shows in the final product coming out of any good woodworking shop.

Maintaining Versatility Across Pallet Types

1. Lubrication Protocols for Moving Parts

Proper lubrication practices matter a lot when it comes to keeping woodworking equipment versatile and functional over time. The main spots where grease goes makes all the difference between smooth running or premature wear. Take pallet nailing machines for instance their bearings, drive mechanisms, and joint areas need consistent attention with oil or grease applications. Putting together a realistic maintenance calendar helps extend component life spans considerably. And dont forget about matching the right lubricant to each part specifications some parts just cant handle certain oils without causing damage down the road. Most equipment makers include detailed care instructions in their manuals because they know from experience what happens when people skip routine maintenance. Machines that get proper upkeep simply break down less often and save money in repair bills long term.

2. Cleaning Procedures for Jam Prevention

Keeping wood nailing machines clean plays a big role in preventing jams and keeping production running smoothly. Without regular maintenance, debris and sawdust tend to build up inside these machines, which can really slow things down or even stop operations completely. Most technicians recommend giving attention to key areas like air passages and nail channels at least once a day to avoid blockages forming. Many shop floor workers will tell anyone who'll listen how much difference proper cleaning makes in their daily work - they simply don't deal with near as many jams and get way better output rates. When shops establish good cleaning habits, they see two main benefits: machines run more efficiently overall and last longer before needing repairs or replacement parts.

3. Wear Plate Inspection Schedules

Checking wear plates on a regular basis keeps woodworking equipment running smoothly, especially important stuff like pallet nailing machines. When someone actually looks at those plates during routine checks, they spot problems early before small issues turn into big headaches for the whole operation. Most shops find that sticking to monthly inspections gives them plenty of warning about worn out parts, which saves money down the road since nobody wants to replace expensive components unnecessarily. The numbers back this up too – manufacturers report around 30% less downtime when maintenance follows a proper schedule. Operators who get into the habit of checking wear plates every few weeks usually see better productivity across the board while their machines last longer than expected. Some woodworkers even keep track of inspection dates right next to their toolboxes so nothing gets forgotten between jobs.

By incorporating these maintenance strategies, we can optimize pallet nailing machines to handle various wood nailing operations effectively, ultimately improving productivity while minimizing machine downtime.