Understanding Wood Pallet Nailing Machine Types

1. American vs. European Pallet Machine Designs

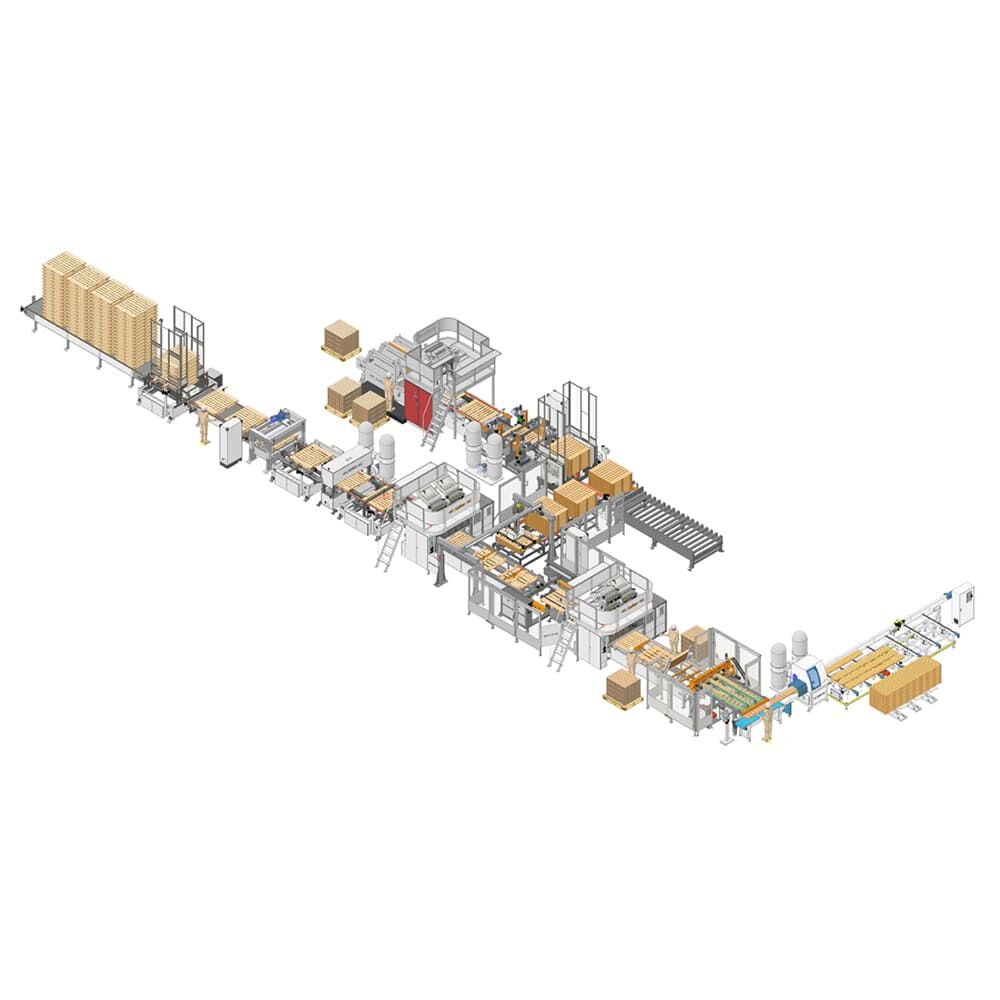

When comparing American and European pallet machine designs, there's a clear difference in approach between the two regions. The US tends to build machines that can crank out pallets fast, using straightforward mechanical systems that keep costs down while maximizing output. This makes sense given the massive warehouses and distribution centers across North America that need constant supply. Meanwhile, Europeans take a different route altogether. Their machines are built for accuracy first, with lots of adjustable parts that let operators handle all sorts of pallet sizes and configurations. Many factories in Europe deal with smaller batches and custom orders regularly, so having equipment that adapts quickly becomes essential rather than just pushing through volume.

Take the American made US Pallet Machine for example. It was built specifically for standard American pallets and comes with full automation thanks to those imported PLC control systems that really speed things up. On the other side of the pond, there's the European Wood Pallet Nailing Machine which relies on advanced CNC tech. These machines are all about precision work and handle various types of Euro pallets that have different requirements across industries. Looking at what's happening in the market right now, American style machines tend to be the go to choice in places where production volume matters most. But when it comes to operations needing more flexibility or custom solutions, European models often win out. This difference actually shapes how companies approach their logistics planning depending on where they operate.

Automated vs. Semi-Automated Systems

Getting to know the differences between automated and semi-automated pallet nailing machines really matters for how well operations run and what kind of money gets spent on labor. The fully automated ones basically take over most tasks without needing much hands-on work from people, which cuts down on payroll expenses quite a bit. These machines come packed with smart programming that handles everything from positioning to actually driving nails into place. For big warehouses or manufacturing plants running nonstop shifts, going all-in on automation makes total sense when efficiency needs to be at its peak level day after day.

Semi automated systems aren't quite as hands off as full automation, but they strike a nice middle ground between human supervision and machine work. These setups need quite a bit more manual involvement particularly at the start up phase and throughout quality checks. However many small businesses find them perfectly suited to their needs when money is tight. According to industry reports, factories that switch from semi auto to fully automatic equipment often see productivity jump around 30%. When deciding which approach works best, look at how big the operation really is, what the financial limitations are, and just how much tailoring will be needed. Both options come with their own advantages, so picking one depends largely on what exactly the business wants to achieve operationally speaking.

2. Specialized Machines for Photovoltaic Pallets

Photovoltaic pallets are really important in the renewable energy field, especially when it comes to moving around those solar panel components that make up complete installations. With so many companies jumping on the green energy bandwagon lately, there's been growing need for custom made equipment to produce these special pallets. Most photovoltaic panels come in all sorts of different sizes that don't fit standard pallet dimensions, so manufacturers have had to adapt their production processes accordingly. The industry now requires machinery capable of dealing with these size variations while still maintaining quality standards. Many factories report challenges when trying to balance cost effectiveness with the ability to handle oversized loads during transportation.

Machines made specifically for photovoltaic pallet construction come packed with specialized tech that helps them hit those tough industry requirements. Take dual side nail guns for instance. These gadgets let workers drive nails from above and below at the same time, which really cuts down on hands-on work and gets things done faster on the production line. Most folks who know this business well point out that many models now have built-in IoT capabilities too. This means better tracking across warehouses and factories while also keeping tabs on performance metrics something we see more and more in smart manufacturing setups within renewable energy fields. And don't forget about all those official certifications hanging around either. They basically guarantee these machines pass current safety tests and run efficiently enough to stay relevant in day to day operations across the whole sector.

Key Selection Criteria for Optimal Performance

1. Assessing Production Volume Requirements

Getting the production numbers right matters a lot when picking out a wood pallet nailing machine. When companies know what kind of output they need, they can match it up with the right specs for their equipment like how fast it works and what it can handle overall. The wrong choice here affects money spent on running things day to day. Too big of a machine sitting around doing nothing wastes resources while something too small just gets bogged down trying to keep up. Take a warehouse that buys an expensive high speed model but only needs basic functionality most days? That's basically throwing cash away. On the flip side, if the machine gets pushed beyond what was planned, everyone ends up waiting longer between batches which slows everything down. We've seen plenty of shops waste time and money because they didn't do their homework on these numbers first. Checking those production figures regularly against what the actual machines can do makes all the difference in keeping things running smoothly without breaking the bank.

2. Nail Type Compatibility (Helical, Smooth, Ring Shank)

Knowing what kind of nails go into wood pallet building matters when picking out the right nailing machine. There are basically three main options: helical, smooth, and ring shank nails. Each has its own strengths depending on what needs to be built. Helical nails really stick things together well, so they work great for heavy duty pallets that need extra strength. Smooth nails are good for basic jobs where speed counts since they go in fast without much fuss. Ring shank nails are special because they won't come loose easily over time, which means pallets last longer during shipping and storage periods. When nail type matches up properly with the machine specs, it makes a big difference in how often maintenance happens and how solid those finished pallets turn out. Machines that can handle several nail varieties cut down on wasted time switching settings, and generally run better for longer periods before needing repairs.

Material Durability and Machine Longevity

When choosing materials for pallets and nailing machines, going for something that lasts longer means less downtime overall, which is pretty important if we want our operations running smoothly. Machines constructed from good quality stuff generally cost less to maintain than cheaper alternatives, according to what most people in the business observe. Strong materials help equipment handle the wear and tear of regular factory work without breaking down so often. Look out for certifications like ISO or DIN ratings when shopping around for wood pallet nailing machines these days. These marks usually point towards better build quality and reliability. Investing in machines that stand the test of time pays off in the long run too. It cuts down on replacement expenses while keeping production moving consistently forward throughout its service life.

Technical Specifications to Prioritize

1. Cycle Speed and Output Capacity

How fast a wood pallet nailing machine cycles through its work really matters when talking about productivity. Basically, cycle speed means how many pallets get assembled by the machine during a certain amount of time, which obviously affects how much gets produced overall. When machines run faster, they generally crank out more product, helping manufacturers hit their production goals without breaking a sweat. Most industries see different levels of output depending on equipment, but going automated makes a huge difference over doing things manually. Take it from experience: fully automatic machines can knock out dozens of pallets every single hour, while those semi-automated versions barely scratch that number. Getting a handle on how cycle speed connects with what comes out of the factory floor and what it actually costs to operate is pretty important stuff when picking the right setup for business needs and staying within budget limits. Focusing on these key specs helps companies keep running smoothly without spending unnecessary money.

2. Pallet Size Adjustability Features

The ability to adjust pallet sizes matters a lot when running machines in custom production setups. With this kind of flexibility, manufacturers can switch back and forth between different pallet dimensions pretty easily, meeting all sorts of client needs. What makes these systems work? Adjustable nailing heads and those fancy PLCs (programmable logic controllers) are big parts of it. These features give operators more options during production runs without getting stuck waiting for machine changes. Real world testing shows that companies save time and money because workers don't have to constantly tweak things manually anymore. Industry pros who've seen these machines in action talk about how valuable they become especially when dealing with frequent product changes. For anyone looking at long term investments, spending on equipment with good adjustment capabilities means the production floor stays nimble enough to handle whatever comes next while keeping things running smoothly day after day.

3. Energy Efficiency and Power Requirements

Wood pallet nailing machines need to be energy efficient these days, mainly because companies want to cut costs and follow regulations at the same time. The newer models come with stuff like variable speed controls and better wiring setups that really cut down on power usage. Some shops report saving around 30% on electricity bills after upgrading from old school machines. When shopping for equipment, most savvy operators look closely at how much power different models consume since this affects both bottom line profits and green credentials. Regulations have been getting tighter too, so manufacturers now build machines according to certain efficiency thresholds set by government agencies. Anyone serious about running a competitive operation should prioritize finding a nailing machine that doesn't drain the wallet month after month while still meeting all those pesky environmental rules everyone keeps talking about.

Evaluating Automation Levels

1. Fully Automatic Systems for High-Volume Needs

Wood pallet nailing systems that run completely automatically were built for places where they need to make lots of pallets quickly, giving both speed and accuracy. What sets these apart is their smart design elements that cut down on wasted time during production, which is why many big operations turn to them when they need massive quantities. Sure, buying one of these全自动 systems upfront costs a pretty penny, but most manufacturers find they save money over time because fewer workers are needed and mistakes happen less often. Take some factories making standard US pallets for example, after switching to full automation they saw their output jump while errors dropped dramatically. For anyone running a serious pallet business looking to crank out volume day after day, spending on an automatic nailing system usually pays off in the long run despite the sticker shock at first glance.

2. Semi-Automatic Solutions for Flexible Operations

Wood pallet nailing machines that work semi automatically give companies a lot of flexibility when dealing with different production requirements. The operators still have to handle some parts manually while other aspects get done automatically, striking a good balance between hands on control and getting things done faster. Training staff properly matters quite a bit if these machines are going to perform at their best level. These kinds of semi automatic setups really shine for businesses needing to tweak production based on what comes up next week or month. Take furniture makers who sometimes need special size pallets or warehouse operators handling various product types. They find these machines super helpful because they can switch between different configurations so easily. The ability to adapt like this keeps operations running smoothly without locking companies into expensive full automation systems that might not fit all their needs.

3. PLC Controls and User Interface Considerations

PLCs have become essential components in modern wood pallet nailing machines, fundamentally changing how these systems work. These controllers allow operators to maintain tight control over every aspect of the nailing process while keeping an eye on machine performance at all times. Many newer models now feature user friendly interfaces with touchscreen displays that make it much easier for workers to adjust settings and monitor operations without needing extensive training. With recent improvements in PLC tech, manufacturers can program their machines quickly and tweak parameters to suit different types of pallets or production runs. This kind of adaptability means companies get better results from their equipment, matching machine output exactly to what's needed on the factory floor day after day.

For businesses evaluating automation levels, considering these aspects will ensure informed decisions that align with operational goals. Embracing the right level of automation will undoubtedly lead to improved efficiency and cost-effectiveness in production processes.