Smart Manufacturing: Automation and AI in Wooden Pallet Production

How automation enhances efficiency and precision in wooden pallet manufacturing

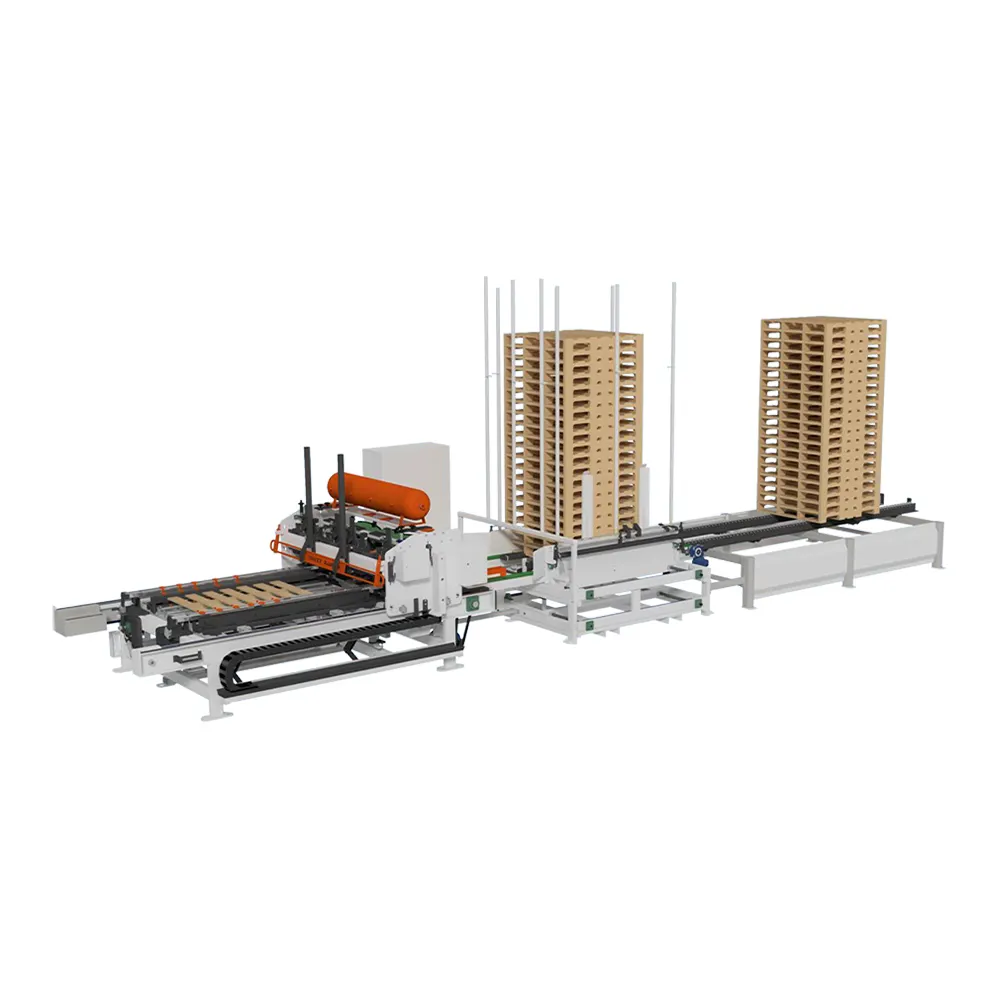

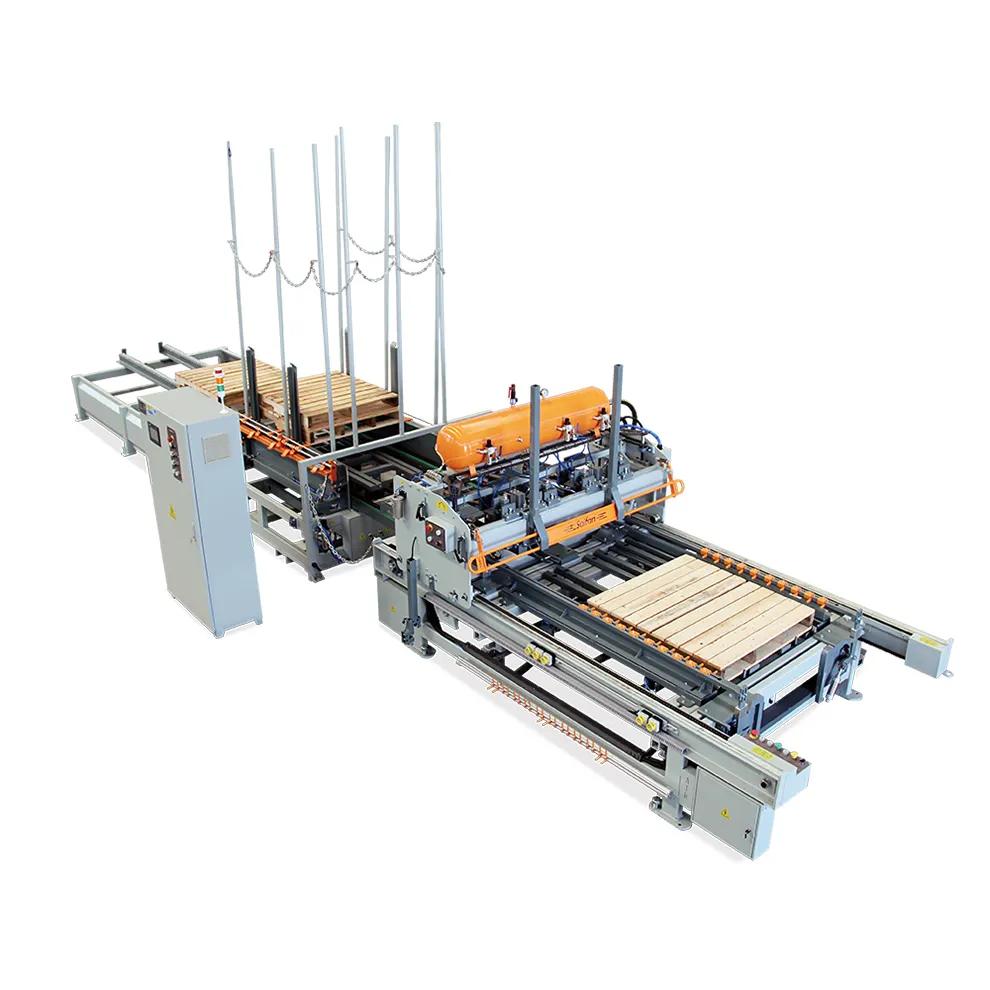

The way we make wooden pallets these days has changed completely from what it used to be back when workers did most of the work by hand. Now there are machines doing all sorts of tasks that used to take hours for people to complete. Take those automatic nailers for instance they can hammer nails into wood at speeds no human could match, getting them placed just right so mistakes happen less often and less good wood gets wasted on bad joints. Conveyor belts run through the factory sorting out different pieces of lumber based on their size and how straight they are, making sure only the best boards actually get put together. All this machinery isn't just about speed either. Manufacturers need to meet very specific requirements for how strong and dimensionally accurate pallets must be when shipping goods around the world, and these automated systems help them hit those targets every time while getting more products made throughout the day.

Integration of robotics in high-speed wooden pallet assembly lines

In the world of fast paced wooden pallet assembly, robotics have become pretty much essential these days. Collaborative robots, or cobots as they're often called, take care of those boring, repetitive jobs that would wear out human workers after a few hours. Take robotic arms for instance they place those deck boards and stringers with surgical precision. Meanwhile, those automated guided vehicles zipping around the factory floor handle all the heavy lifting when it comes to moving parts from station to station without anyone needing to lift a finger. The whole setup lets factories run non stop day and night with hardly any breaks needed, which is exactly what modern manufacturing needs to keep up with customer demands. Looking at numbers from early 2023 shows that most big name pallet makers had already rolled out some kind of robot system into their operations, showing how serious the industry is about cranking out volume efficiently.

AI-driven quality control and real-time workflow optimization

AI takes quality control and operations to another level when combined with computer vision tech and machine learning algorithms. On factory floors today, smart cameras are scanning every single pallet looking for problems like crooked boards, missing fasteners, or weak spots in construction materials. When something looks off, the system flags it immediately so workers can fix issues right there instead of letting bad products move further along the assembly line. What makes these systems really valuable is their ability to analyze past performance data. They spot patterns that humans might miss, which helps predict when equipment will need servicing and when to schedule different tasks. This kind of foresight cuts down on those frustrating production delays and unexpected shutdowns that waste time and money. Manufacturers see better consistency in what they produce, spend less time dealing with breakdowns, and get much better control over how resources are used throughout the entire facility.

Sustainable Resource Management: Closed-Loop Systems and Pallet Lifecycle Extension

Principles of sustainability and closed-loop pallet systems in modern logistics

Closed loop pallet systems work pretty much like what they sound like. They grab those old pallets back from wherever they've been, check them over, fix anything broken if needed, then send them right back into circulation rather than just throwing them away. The whole thing cuts down on how much new wood we need to cut down, means less trash overall, and also makes companies less dependent on constantly making brand new stuff. A lot of modern logistics companies are jumping on board with these kinds of packaging programs lately. It helps build those sustainable material loops that everyone keeps talking about these days. Plus it supports environmental targets because there's less digging up resources and fewer things ending up in landfills.

Pallet reconditioning and repair programs: Cost savings and lifecycle extension

Wooden pallet reconditioning can save companies money while getting more years out of their equipment. When pallets get damaged during shipping or storage, instead of throwing them away, many businesses send them to repair centers where workers fix what needs fixing. The cost? Usually under half price compared to buying brand new ones. What do these repair shops actually do? They take out rusty nails, replace broken boards, and reinforce weak spots so the pallet works just like it did when first purchased. For warehouse managers, this means spending less on buying fresh stock and tossing out fewer damaged items each month. Budget planning becomes easier too since there's less surprise expense coming through. Plus, keeping old pallets in circulation cuts down on waste going to landfills. Companies that run these programs aren't just being economical they're also doing their part for the environment by reducing the need for constant manufacturing of new wooden products.

Industry data: Over 350 million wooden pallets reconditioned annually in the U.S.

Reconditioning on a massive scale across America shows just how well circular economy principles work for wooden pallets. Every single year, somewhere around 350 million old pallets get fixed up and put back into circulation instead of being thrown away. That means fewer trees need cutting down for new pallet manufacturing. And what's really impressive is that all these repairs keep roughly millions upon millions of tons of scrap wood out of our landfills nationwide. The wooden pallet sector has basically created its own recycling system right within the supply chain, offering real world proof that sustainable packaging doesn't have to be expensive or complicated.

Waste Reduction and Carbon Footprint: Green Innovations in Wooden Pallet Production

Innovations in recycling and wood waste management to minimize landfill use

Manufacturers who are thinking ahead have started seeing wood waste not just as something to throw away but actually as something useful they can work with. New tech makes it possible to sort out good pieces of lumber from the damaged bits, then send those scraps off to make things like particle board, garden mulch, or even composite panels for construction projects. Some operations manage to use around 90-95% of all their materials, which means way less stuff ending up in landfills than before. What's interesting is how companies in older industries are finding ways to go green without hurting their bottom line or slowing down production speeds at all.

From scrap to energy: Biomass conversion in sustainable wooden pallet facilities

If leftover wood scraps just aren't going to make it into anything else, there's still something good we can do with them through biomass conversion. The process works pretty well too gasification systems take all those little bits of sawdust, scrap pieces, and wood shavings and turn them into actual heat energy. This powers things like kilns and other machinery around the factory floor. What makes this approach so great is that it cuts down on our reliance on regular old fossil fuels while also saving money on running costs. Some major manufacturing facilities have already managed to run almost entirely on their own generated power from these biomass systems during normal working hours. Not only does this make operations greener, but it also means they can keep producing even when outside energy sources get unreliable.

Strategies for reducing carbon emissions in wooden pallet production

Reducing carbon starts at the forest level and continues throughout manufacturing processes. Many top companies now get their wood from nearby sources to slash emissions from transport. They also invest in better kiln technology which cuts down on energy needed for drying by around 40 percent. These practices fit into bigger industry trends toward cutting carbon footprints. The EPA has actually highlighted these approaches in their Sustainable Materials Management initiative as smart ways to lower environmental effects throughout the whole supply chain network.

Adoption of low-emission kilns and electric forklifts in manufacturing plants

Facilities across the industry are swapping out old drying systems for new low-emission kilns equipped with smarter controls and cleaner burning fuels to cut down on harmful emissions. At the same time many warehouses have started adopting electric forklifts instead of their gas powered counterparts. These electric models don't emit exhaust fumes and actually make the air inside factories much cleaner. The combination of these changes has led to safer working conditions while also making operations greener overall. With batteries getting better all the time and more charging stations popping up everywhere, we're seeing electric equipment become pretty much standard in modern wood pallet production facilities these days.

FAQs

What are the main benefits of automation in wooden pallet manufacturing?

Automation improves efficiency and precision by speeding up tasks that used to be manual. It reduces errors and wastage of materials while ensuring that pallets meet specific strength and accuracy standards.

How do closed-loop systems contribute to sustainability in pallet production?

Closed-loop systems involve recycling old pallets instead of discarding them, which conserves resources, reduces waste, and supports environmental targets by minimizing reliance on new materials.

What role does AI play in quality control within pallet manufacturing?

AI, combined with computer vision and machine learning, helps detect discrepancies in pallets instantly and analyzes data for optimizing workflows, predicting equipment maintenance, and preventing production delays.

Table of Contents

- Smart Manufacturing: Automation and AI in Wooden Pallet Production

- Sustainable Resource Management: Closed-Loop Systems and Pallet Lifecycle Extension

-

Waste Reduction and Carbon Footprint: Green Innovations in Wooden Pallet Production

- Innovations in recycling and wood waste management to minimize landfill use

- From scrap to energy: Biomass conversion in sustainable wooden pallet facilities

- Strategies for reducing carbon emissions in wooden pallet production

- Adoption of low-emission kilns and electric forklifts in manufacturing plants

- FAQs