Labor Shortages Accelerating Adoption of Fully Automated Pallet Production Lines

Shrinking Industrial Workforce in North America and Europe

Manufacturers are really feeling the pinch from ongoing worker shortages, which has pushed many to invest in completely automated pallet production systems. According to data from The Manufacturing Institute, we could see around a quarter fewer manufacturing jobs across North America by 2030. Things look even worse in Europe where factory job openings jumped nearly 40% last year alone. The problem hits hardest in those constant-on-the-move pallet stacking positions. These jobs have become notorious for causing repetitive stress injuries, leading to about one third of workers leaving each year. That's why automation makes so much sense here it allows machines to work nonstop without worrying about fatigue or injury risks, something traditional methods just can't match.

| Labor Factor | Manual Operation | Automated Line |

|---|---|---|

| Workers per shift | 8–12 | 2–3 |

| Annual turnover rate | 45% | 8% |

| Labor cost reduction potential | — | 68% |

Faster ROI: How a Tier-1 Food Manufacturer Reduced Onboarding Time by 78%

One major food company saw their return on investment come in at just 14 months flat out - that's about 40 percent quicker than what most folks see in this business - after they rolled out a completely automated system for making pallets. The whole setup uses smart grippers powered by artificial intelligence, which basically wiped out those old fashioned six week training periods for operators. Now new hires can get up to speed in just five days instead. Production rates shot up by around 35% too. And according to some research from Ponemon Institute back in 2023, they saved themselves nearly $740 thousand each year on injuries alone. What really stands out though is what happened to the workers who lost their jobs. About nine out of ten found new positions doing quality checks and other tasks that actually add real value to the operation. This shows that when companies plan their automation right, they don't just boost productivity but also create better opportunities for their people.

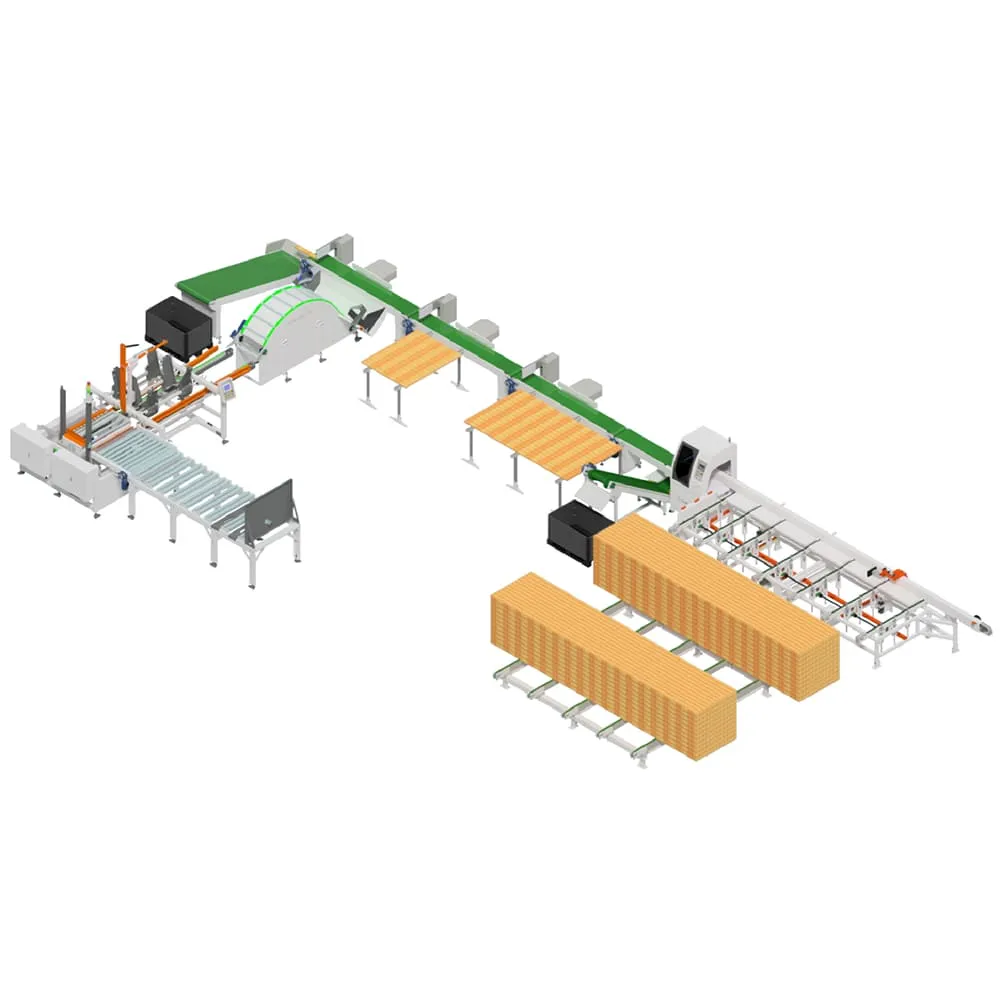

Seamless Smart Manufacturing Integration in Fully Automated Pallet Production Lines

MES/WMS Synchronization Cuts Pallet Dispatch Latency by 41%

When Manufacturing Execution Systems (MES) communicate directly with Warehouse Management Systems (WMS), it basically removes those tedious manual steps in our fully automated pallet production lines. The connection allows for seamless coordination between production and logistics operations. As soon as a pallet finishes production, the system automatically starts the dispatch process without any delays. Companies have seen some impressive results too. These synchronized workflows slash pallet staging errors down by around 92%. What's even better is that dispatch times have dropped dramatically from an average of 38 minutes all the way down to just 22 minutes. That represents a 41% speed boost according to research conducted at 17 different facilities last year by the Material Handling Institute.

| System Integration Benefit | Impact Metric | Outcome |

|---|---|---|

| Automated job-to-dispatch routing | Real-time MES/WMS handshaking | Zero manual data entry required |

| Digital twin validation | Protocol compliance checks | 99.4% first-pass accuracy rate |

| Dynamic route optimization | Forklift travel reduction | 27% fewer warehouse movements |

The bidirectional data flow allows WMS to communicate inventory constraints back to production, dynamically adjusting pallet batch sizes. This closed-loop control prevents warehouse congestion while sustaining 98.6±0.3% line utilization—proving how interoperability unlocks continuous throughput in automated pallet environments.

Operational Flexibility: Rapid SKU Adaptation and Scalable Batch Handling

Sub-8-Minute Changeover Between SKU Families Using Digital Twin Validation

Pallet production lines that run fully automated offer something pretty amazing when it comes to how flexible operations can be, all thanks to digital twin technology. The engineers working on these systems rely on live sensor information combined with detailed material analysis to test out new pallet designs virtually first. This approach completely removes the need for those time consuming physical trials that used to slow everything down. What does this mean in practice? Changeovers between different product groups now happen in just under eight minutes flat. That's actually a massive jump forward compared to older systems where this same process took way longer. Before any actual changes get implemented, digital twins check everything from weight distribution to stacking arrangements and stability factors. Manufacturers report keeping their machines running at around 99.4% efficiency even when switching between products. They adapt quickly to whatever happens next season or whenever customers ask for something special, no waiting around for equipment adjustments. For companies dealing with unpredictable markets, this kind of responsiveness turns what would normally be problems into real business advantages as they keep producing goods efficiently despite changing conditions.

FAQ Section

Q: Why are manufacturers adopting fully automated pallet production lines?

A: Manufacturers are facing labor shortages and high employee turnover rates, particularly in the pallet stacking positions that lead to repetitive stress injuries. Automation helps resolve these issues by offering nonstop work without fatigue or injury risks.

Q: How do automated pallet production lines affect production throughput?

A: With fully automated lines, production throughput sees a significant boost, often increasing output by up to 220% compared to semi-automated systems. This is due to continuous operation and synchronized handling of materials.

Q: What are the benefits of integrating MES/WMS in automated pallet production?

A: Integrating MES with WMS ensures seamless coordination between production and logistics operations, reducing dispatch latency and staging errors significantly.

Q: How flexible are fully automated pallet production lines in handling different products?

A: Thanks to digital twin technology, automated lines can adapt quickly to different products, completing changeovers in under eight minutes while maintaining high efficiency.